Blending method of small-space crushing soybean milk machine

A technology of small-space crushing and small-space pulverizer, which is applied to milk substitutes, beverage preparation devices, household appliances, etc., and can solve the problems of reducing the quality of slurry, potential safety hazards, and affecting the taste of soy milk for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

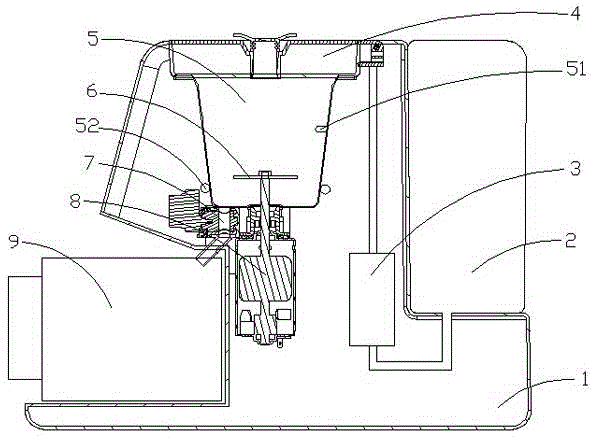

[0028] Such as figure 1 As shown, the small-space crushing soybean milk machine of this embodiment includes a body 1, a water tank 2 is assembled on the body 1, the water tank is connected with the instant heating device 3, and the small-space pulverizer 5 is arranged on the top of the body 1, which is the output of the heating device. The nozzle leads to the small space pulverizer, the inner wall of the small space pulverizer 5 is provided with a temperature measuring part 51, the heating device 52 is arranged on the outer wall of the small space pulverizer 5, the motor 8 is arranged at the bottom of the small space pulverizer 5, and the motor shaft Through the bottom of the small space pulverizer, the top of the motor shaft is provided with a pulverizing knife 6, the pulverizing knife 6 is inside the small space pulverizer body, and the bottom of the small space pulverizer 5 is provided with a slurry discharge valve 7 for discharging slurry / paste to the slurry receiving cup 9...

Embodiment 2

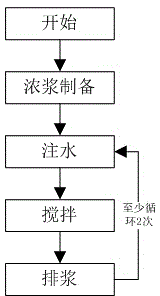

[0050] Such as image 3 As shown, the difference between this embodiment and the above-mentioned embodiments is that the blending stage starts with homogeneous blending, that is, after the thick slurry is prepared, water is first injected into the pulverizer in a small space and stirred to complete a homogeneous blending, so that the small space The slurry in the space pulverizer is diluted once before the first pulping. After the first pulping, complete the whole blending stage according to the steps of Embodiment 1.

[0051] The volume of water injected into the small space pulverizer for the first homogeneous blending is A0, 10%V1≤A0≤25%V1. The volume of discharging the slurry in the small space pulverizer into the pulp receiving cup for the first time is B1, B1<40%V1, and the volume of discharging the slurry in the small space pulverizer into the pulp receiving cup for the second time is B2, 30%V1≤B2≤60%V1.

[0052] Still taking the soya-bean milk of 1200ml as an exampl...

Embodiment 3

[0056] The difference between this embodiment and the above-mentioned embodiments is that in this embodiment, a heating device is provided at the bottom of the pulp receiving cup. After the first pulp discharge is completed, the control system of the soybean milk machine will control the heating device to heat, so that The slurry in the slurry cup is in a boiling state, and when the slurry discharged for the second time enters, it is convenient for the slurry of two different concentrations to be fully mixed.

[0057] Of course, if a heating device is provided, the slurry in the slurry cup can also be heated to keep it warm, so as to better bring user-friendly experience. Or carry out the infusion stage in the slurry cup.

[0058] Of course, it is also possible to cook the slurry in a small-space pulverizer and then discharge it. At this time, you can choose to install an ultrasonic wave or an oscillating device at the bottom or around the pulp cup so that during the second an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com