Traction-type subsoil fertilization and soil-rock separation machine

A soil-rock separation and traction technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problem that the effect of screening and separation and sand-stone coverage cannot meet the production requirements of the recovery of sandy field properties, and the boundary between sandy-stone and soil layers is not very obvious , high power consumption and other issues, to achieve the effect of complete functions, large vibration swing, and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

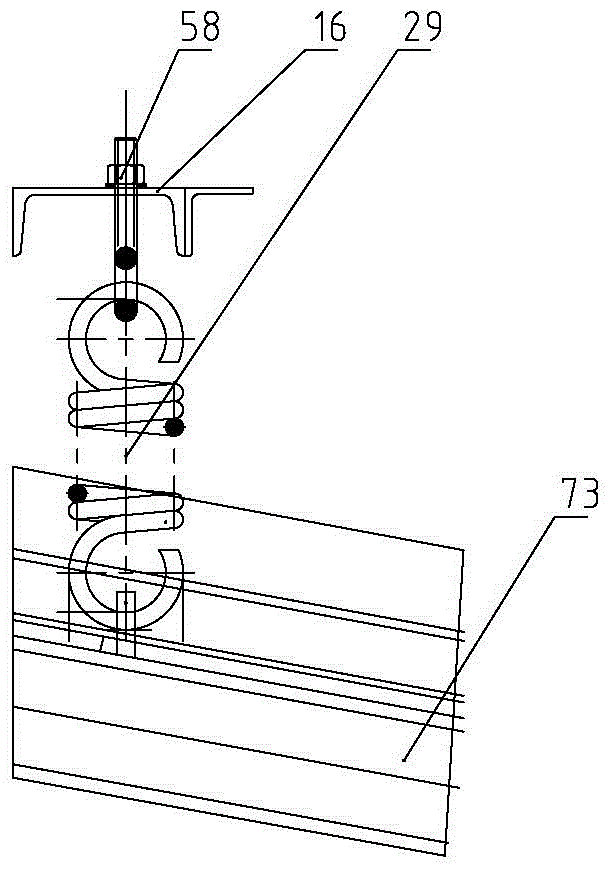

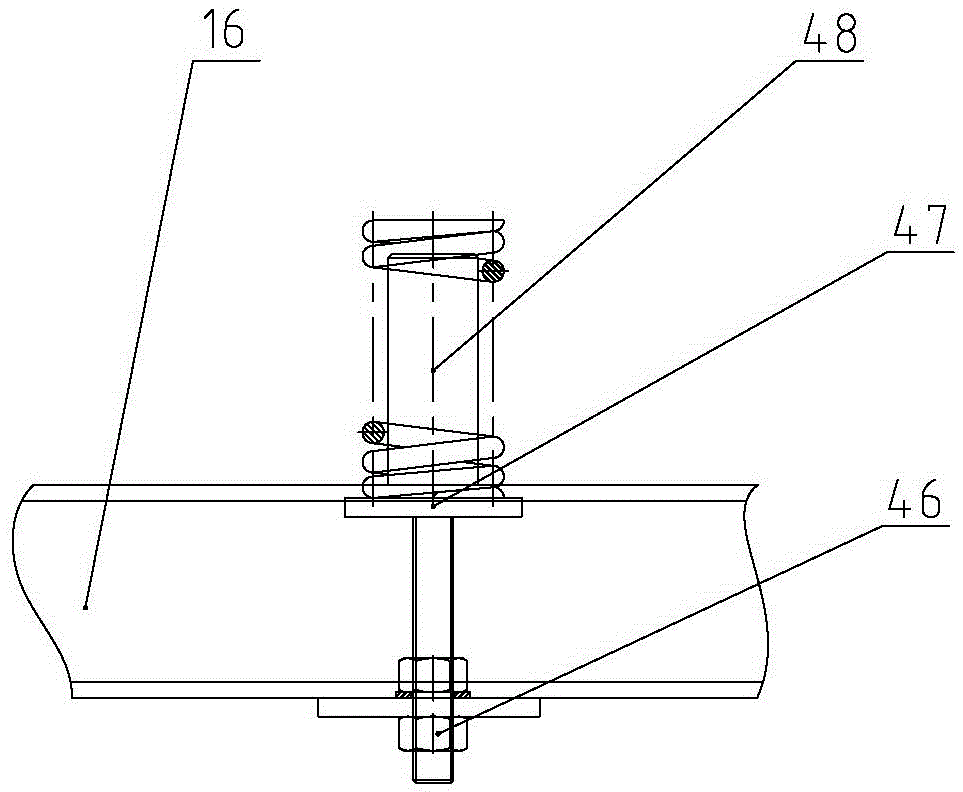

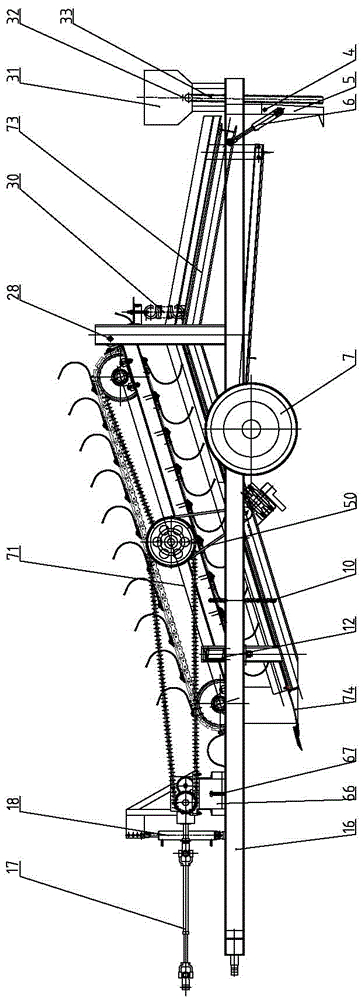

[0038] combined with figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11 illustrate an embodiment of the present invention.

[0039] The present invention is a traction-type subsoiling and fertilizing soil-rock separation integrated machine, which comprises components such as a vehicle frame 16, a chain scraper 71, a vibrating screen 73, a subsoiling shovel 5, and a fertilizing machine 31.

[0040] Wheel 7 is installed in the middle part of vehicle frame 16 of the present invention, is traction frame 69 at the head of vehicle frame 16, and traction frame 69 and wheel 7 can borrow the wheel of the traction frame of agricultural four-wheel vehicle. The traction-type trailer is adopted, which can adapt to various terrains, and the walking speed is stable and fast.

[0041] The rear end of the chain scraper 71 is hinged on the vehicle frame 16 through the hinge shaft 28, and the front end of the chain scraper 71 is connected to the vehicle frame 16 by two hydraulic cylinders 18 with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com