A new type of combined connection fittings for jumper pipes of pipe busbars

A combined connection and jumper tube technology, applied in the field of power transmission and distribution, can solve the problems of difficult installation, limited wire flow capacity, high cost, etc., and achieve the goal of reducing installation workload, reducing tower height, and reducing deflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

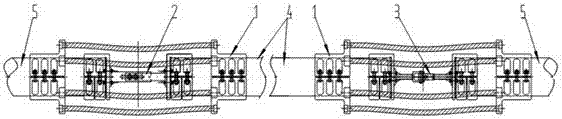

[0015] from figure 1 It can be seen that the connection fittings in the present invention are all composed of pipe busbar clamps, jumper pipe clamps and key components, wherein the rigid sliding fittings and universal joint fittings have the same clamp structure at both ends, and are all disc-type clamps. The clamps of the fastening and telescopic diversion metal fittings respectively clamp the pipe busbar body and the pipe busbar jumper pipe body. There are small holes on the edge extension of the fixture, and the small holes are used to install flexible wires.

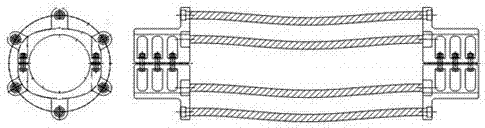

[0016] figure 2 It is a telescopic diversion fitting, and its components are four fixtures with the same structure and six flexible wires. The fixtures are all semicircular structures with corresponding bolt holes on them. The semicircular structures are butted in pairs and sleeved on the busbar , fastened by screws.

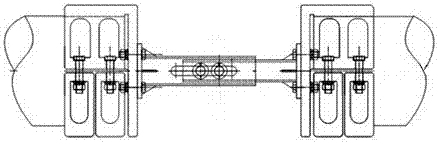

[0017] image 3 It is a rigid sliding fitting, and its bus bar clamp and jumper tube clamp are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com