Lifting counterweight and crane

A technology for cranes and movable counterweights, which is applied in the direction of cranes, counterweights, mechanical equipment, etc. It can solve the problems of asynchronous operation of multiple oil cylinders and high production costs, and achieve the effects of low cost, reduced counterweight weight, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

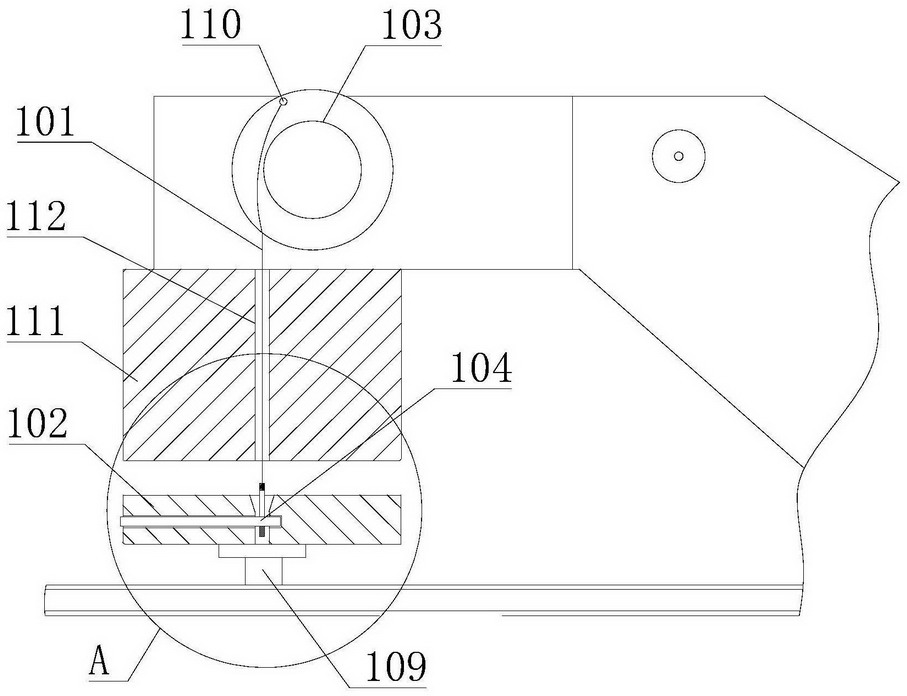

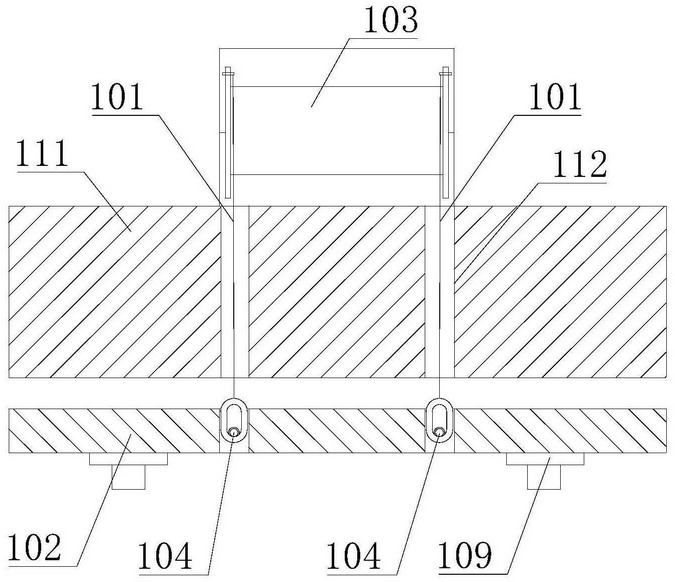

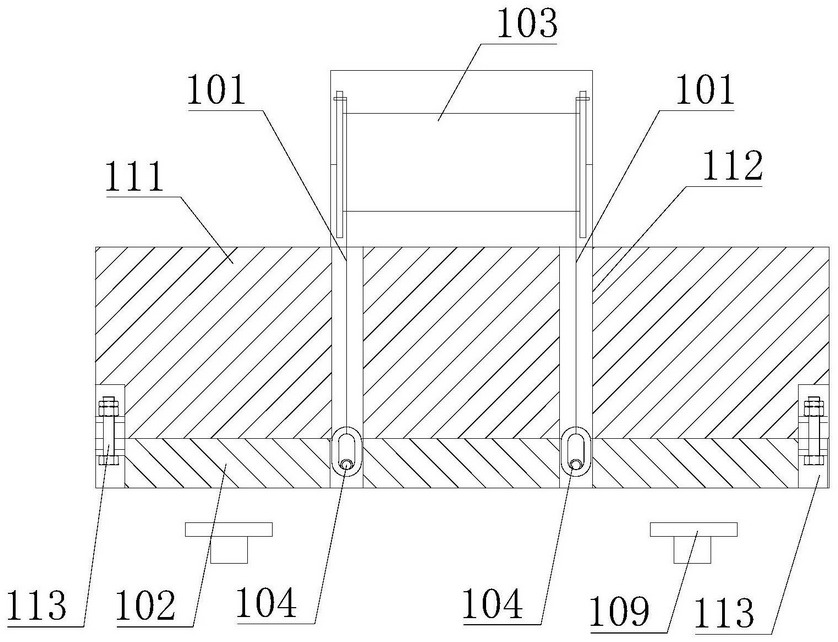

[0035] see Figure 1 to Figure 4 As shown, the lifting counterweight provided by the present application is used for a crane, and the lifting counterweight includes a connecting rope 101, a movable counterweight 102 and a fixed counterweight 111; one end of the connecting rope 101 is connected with the reel 103 of the crane, and the connecting rope 101 The other end is connected with the movable counterweight 102 , and the reel 103 rotates to drive the connecting rope 101 to lift, so that the connecting rope 101 pulls the movable counterweight 102 close to or away from the fixed counterweight 111 .

[0036] The counterweight of the crane mainly plays a role in maintaining the balance of the car body. For some large-tonnage cranes, in addition to being equipped with fixed counterweights 111, movable counterweights 102 also need to be added. The liftable counterweight provided by the present application promotes the movable counterweight 102 by setting the connecting rope 101, ...

Embodiment 2

[0046] The liftable counterweight in the second embodiment is an improvement on the basis of the above embodiment. The technical content disclosed in the above embodiment will not be described repeatedly, and the content disclosed in the above embodiment also belongs to the content disclosed in the second embodiment.

[0047] see Figure 1 to Figure 4 As shown, in the optional solution of this embodiment, when the volume of the fixed counterweight 111 is too large, the connecting rope 101 connected with the reel 103 and the movable counterweight 102 needs to pass through the fixed counterweight 111. A through hole 112 is opened on the counterweight 111 , so that the connecting rope 101 can pass through the through hole 112 to be connected with the movable counterweight 102 .

[0048] It should be noted that the number and positions of the through holes 112 and the number and positions of the connecting ropes 101 need to be opened correspondingly.

[0049] In the optional solu...

Embodiment 3

[0052] Embodiment 3 of the present application provides a crane, which includes the liftable counterweight of any one of the above embodiments, and thus has all the beneficial technical effects of the liftable counterweight of any one of the above embodiments, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com