Piezoelectric ceramic sensor oscillator

A sensor vibrator, piezoelectric ceramic technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric device or electrostrictive device components, circuits, etc., can solve the problem of the large size of the transducer structure , small size and low sensitivity, etc., to achieve high sensitivity, improve sensitivity, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

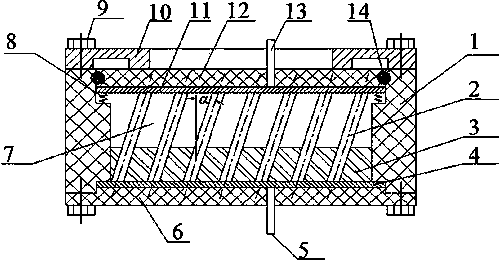

[0017] An embodiment of the present invention provides a piezoelectric ceramic sensor vibrator, such as figure 1 As shown, the sensor vibrator includes a housing 1, several piezoelectric ceramic columns 2, a bracket 3, an upper plate 11, a lower plate 4, an upper cover plate 12, a lower cover plate 6, an upper terminal 13, and a lower terminal 5. , a pressure plate 10, a plurality of piezoelectric ceramic columns 2 are fixedly arranged in the housing 1 through a bracket 3, and an upper plate 11, an upper cladding plate 12, and a pressure plate 10 are sequentially arranged above the plurality of piezoelectric ceramic columns 2, and the A lower pole plate 4 and a lower cover plate 6 are sequentially arranged under several piezoelectric ceramic columns 2. The upper pole plate 11 is connected to the upper terminal 13 and passes through the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com