Tissue chip receptor blank wax block preparation device and using method thereof

A technology for tissue chips and wax blocks, applied in the field of demolding devices and molds for tissue chips, can solve the problems of low demolding accuracy of workers, unadjustable size of wax blocks, lack of demolding devices, etc., to avoid property loss, The effect of eliminating processing technology and accurate demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

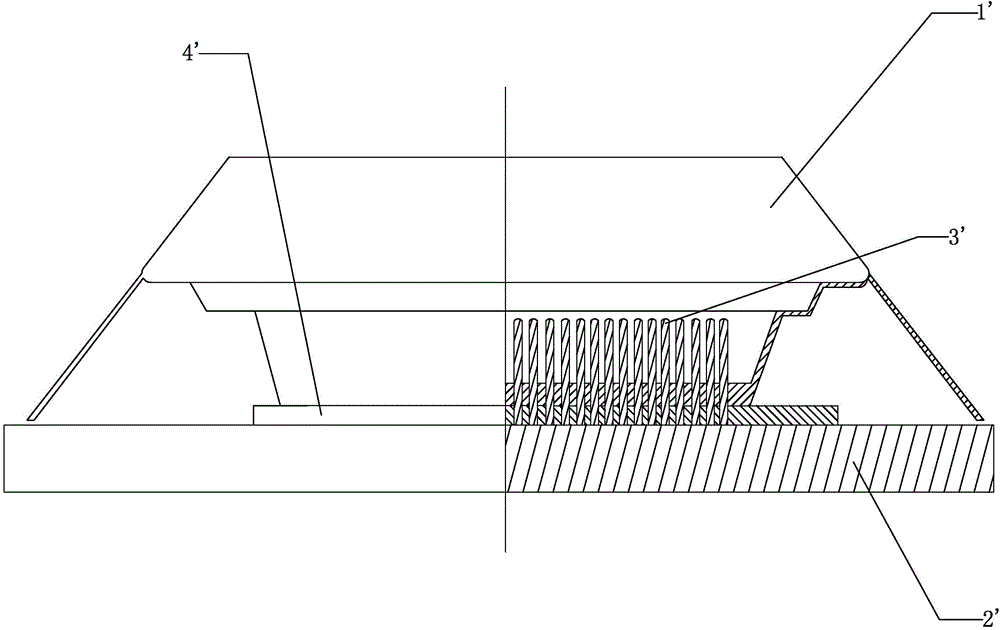

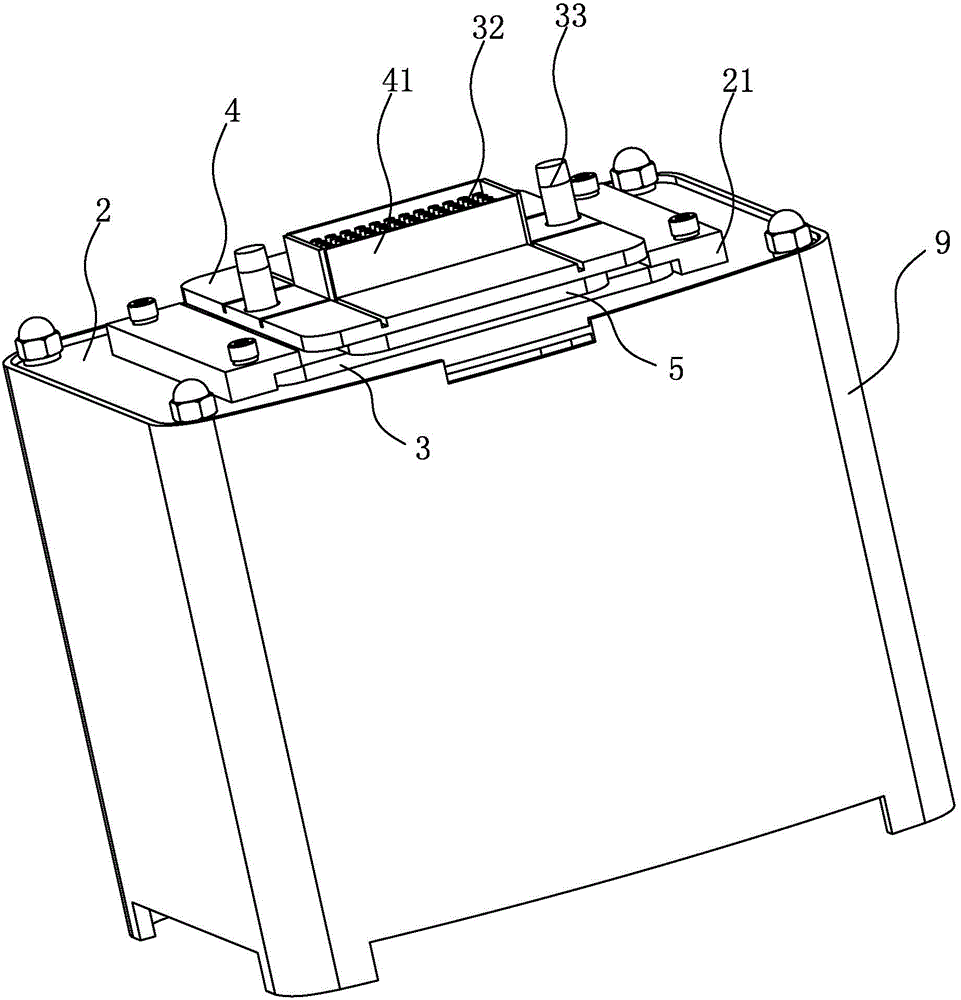

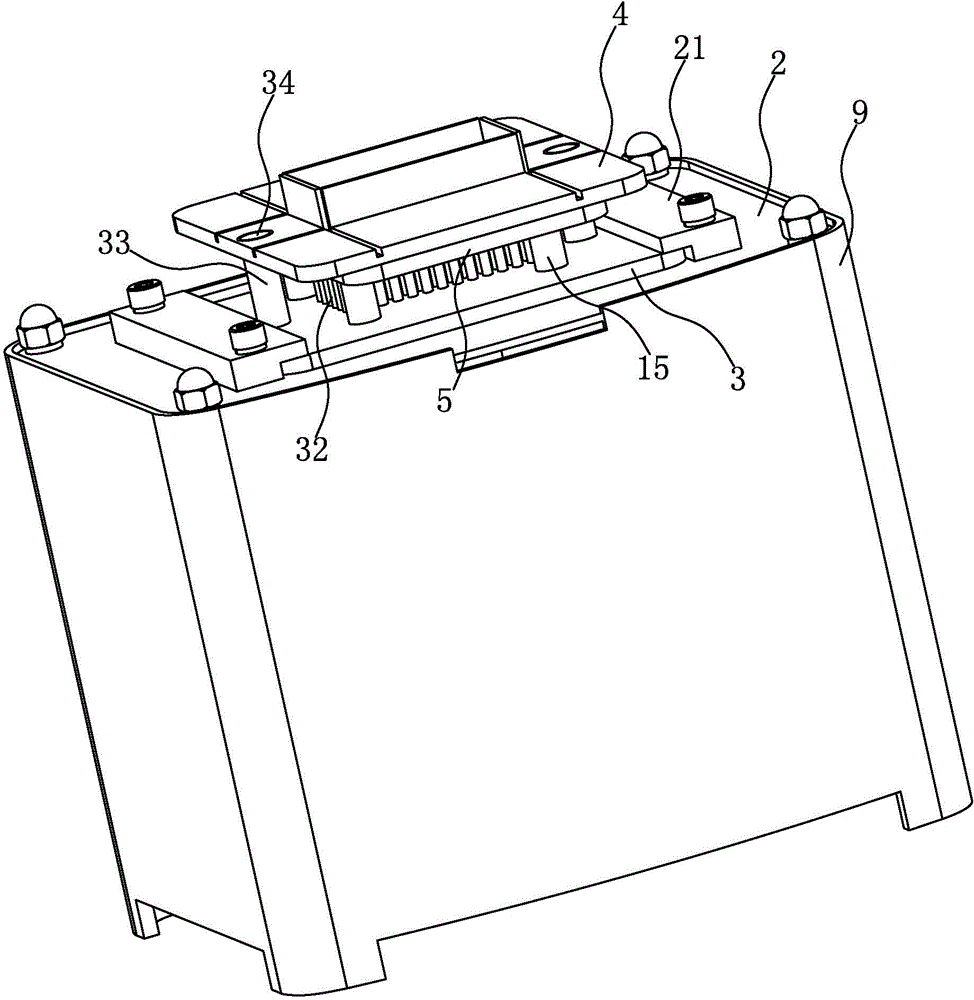

[0042] Such as Figure 2-7As shown, the tissue chip acceptor blank wax block preparation apparatus of the present invention includes a tissue chip array wax block mold. The tissue chip array wax block mold includes an array column plate 3 , an array column 32 , an array hole plate 4 , and a backing plate 5 . There are multiple array columns 32, and a plurality of array columns 32 form a cuboid. The front, back, left and right sides of the cuboid form a peripheral surface, and the center of the backing plate 5 is provided with a rectangular hole, and the peripheral surface matches the rectangular hole. , so that the backing plate 5 is set on the peripheral surface of the cuboid formed by the array columns 32 . It also includes a base 11, a lifting device 12, a push column 13, a push plate 14, a push rod 15, a guide rail seat 2, a guide rail 21, a longitudinal baffle 22 and a seat push hole 23.

[0043] Such as image 3 As shown, the base 11 is fixed on the bottom plate of th...

Embodiment 2

[0055] The difference between the second embodiment and the first embodiment is that the cross-sectional shape of the guide post 33 is a rounded rectangle, and the shape of the guide hole 34 is a rounded rectangular hole matched with the guide post 33 .

[0056] The number of said push rods 15 is three, and the three push rods 15 are distributed in an isosceles triangle on the push plate 14 . The seat pushing hole 23 on the guide rail seat 2 is in clearance fit with the push rod 15 .

[0057] During use, put the array column plate 3 of the array wax block mold into the guide rail and reach the position where the longitudinal baffle 22 is limited, and the push hole 31 of the detection plate and the push hole 23 of the seat are coaxial and can be used.

[0058] Such as Figure 8 As shown, a method for preparing a medium-sized wax block with a tissue chip receptor blank block preparation instrument comprises the following steps:

[0059] A. Drop the lifting device 12 to the low...

Embodiment 3

[0065] The difference between Embodiment 3 and Embodiment 1 is that the number of push rods 15 is two, and the cross-section of the push rods 15 is a long rectangle with rounded corners. The seat pushing hole 23 on the guide rail seat 2 is in clearance fit with the push rod 15 .

[0066] Such as Figure 9 As shown, a method for preparing a small size wax block with a tissue chip receptor blank block preparation instrument comprises the following steps:

[0067] A. Drop the lifting device 12 to the lowest point;

[0068] B. Insert the left vertical board and the rear vertical board into the left groove and the rear groove respectively. The left end face of the rear riser is close to the front end face of the left riser and the middle part of the rear surface of the front riser is close to the front face. The front riser is inserted between the array columns 32. The vertical board is inserted between the array columns 32, and the rear end surface of the right vertical board i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com