Composite bearing deflection limiting device for stirring shaft

A composite bearing and stirring shaft technology, which is applied in the directions of shafts and bearings, bearings, bearing components, etc., can solve the problems that the stirring device cannot work normally, the bearings and the shaft are stuck, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Here, the specific structure and workflow of the present invention will be further described through the following specific implementation methods:

[0032] For ease of understanding, the ideal axis of the stirring shaft 10 is first described here as follows: the ideal axis of the stirring shaft 10, that is, regardless of installation errors and other factors that cause the shaft body of the stirring shaft 10 to deflect, is completely ideal when the stirring shaft 10 is in a completely ideal position. The axis in the vertical state of the shaft body.

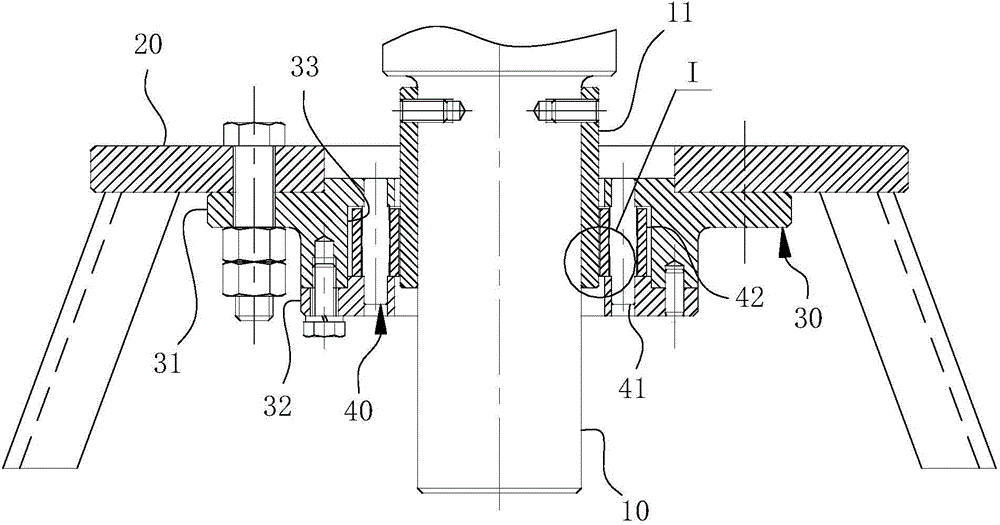

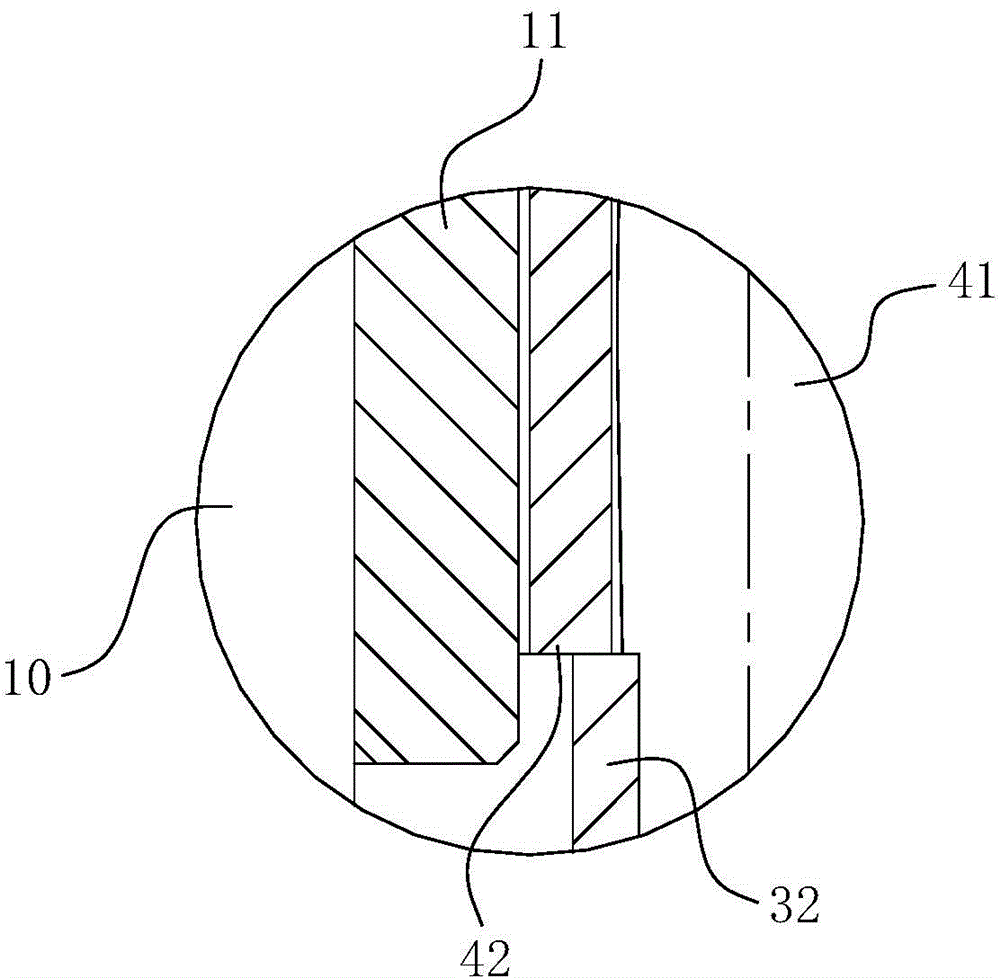

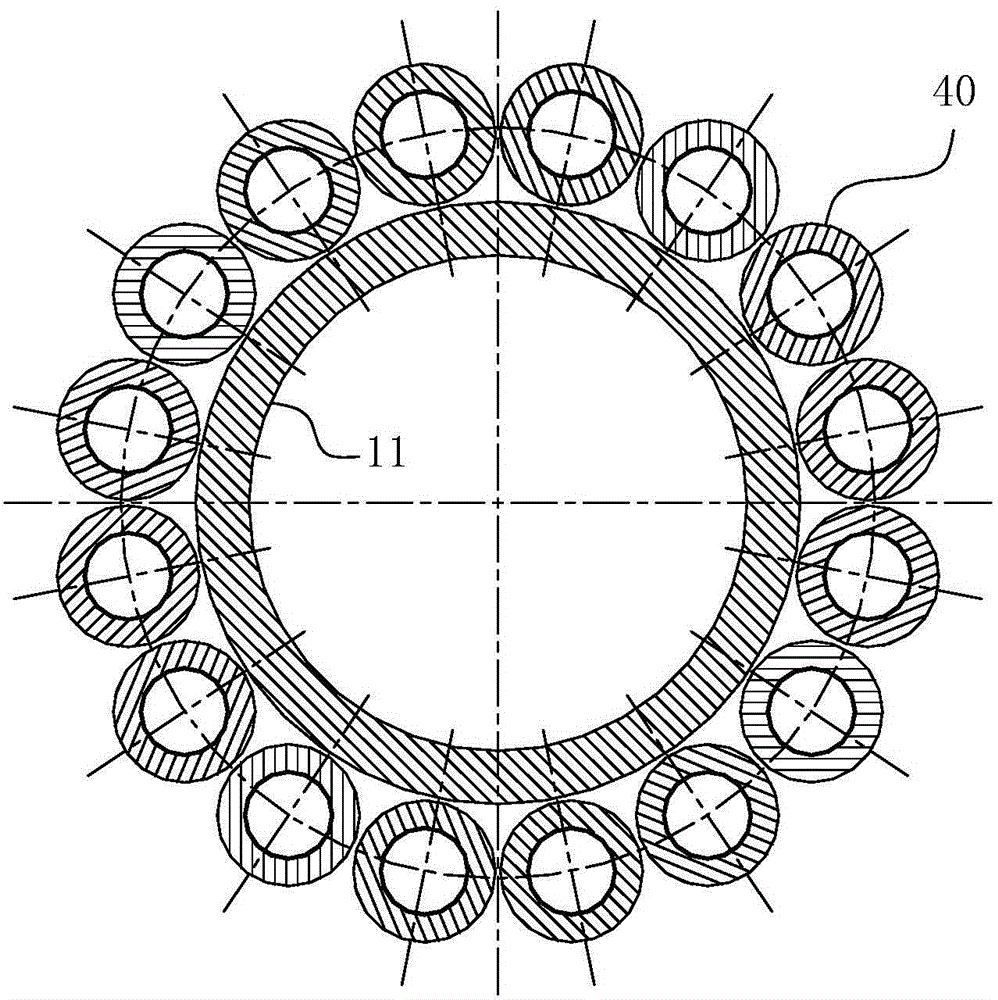

[0033] The specific structure of the present invention is as Figure 1-6As shown, it includes an outer ring sleeve 30 sleeved on the shaft body of the stirring shaft 10 , and the outer ring sleeve 30 is fixed in the inner cavity of the agitator with a support frame 20 . The axis of the outer ring sleeve 30 is arranged coaxially with the ideal axis of the stirring shaft 10, that is, the axis of the stirring shaft 10 in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com