Switchable successive/secondary boosting structure and control method

A two-stage supercharger and supercharger technology, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problem of unsatisfactory matching of exhaust gas turbochargers and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

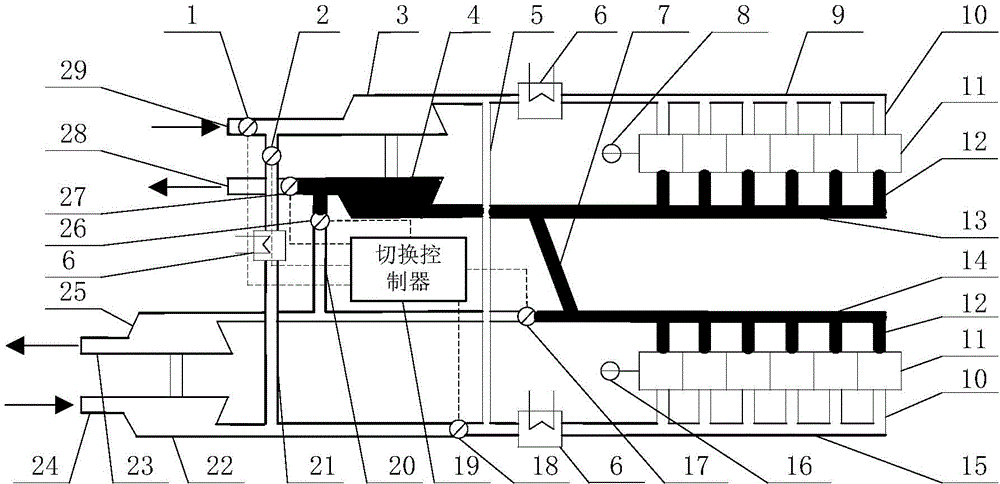

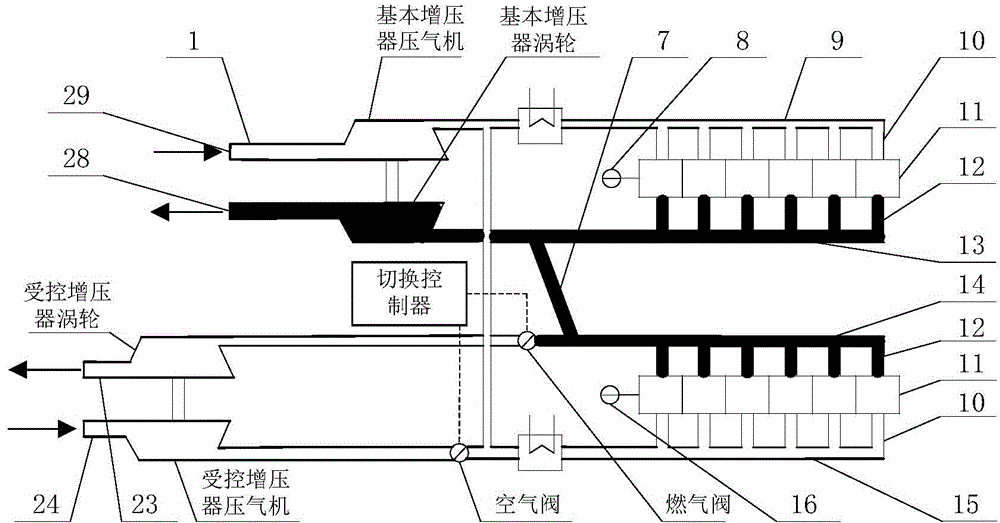

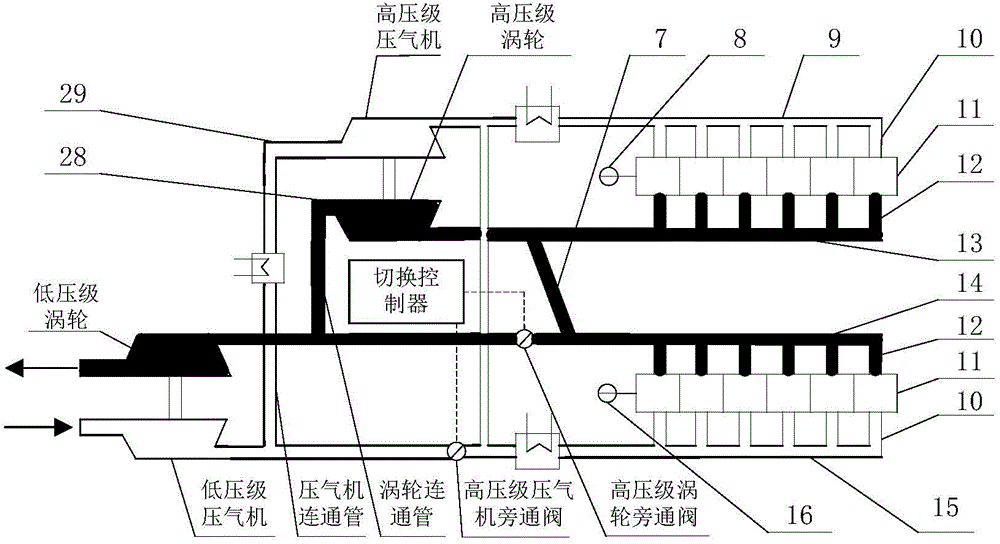

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0026] combine Figure 1~4 , the present invention integrates the two supercharging structures of successive supercharging and two-stage supercharging through modification, and proposes a control method for switching between the two supercharging forms, realizing the organic combination of successive supercharging and two-stage supercharging, so that the two The advantages and disadvantages of the two supercharging forms complement each other. The present invention can be used in the supercharging system of two or more exhaust gas turbochargers. Taking two exhaust gas turbochargers as an example, it can realize single turbocharger, two turbochargers in parallel-sequential supercharging, two turbochargers Supercharger series-two supercharging three modes.

[0027] The structure of the device of the present invention comprises a basic supercharger compressor intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com