PM particle trap regeneration device

A particle trap, regeneration equipment technology, applied in mechanical equipment, machines/engines, engine components, etc., can solve the problems of poor combustion effect, low backflushing gas pressure, energy waste, etc., and achieve excellent regeneration effect and loss. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

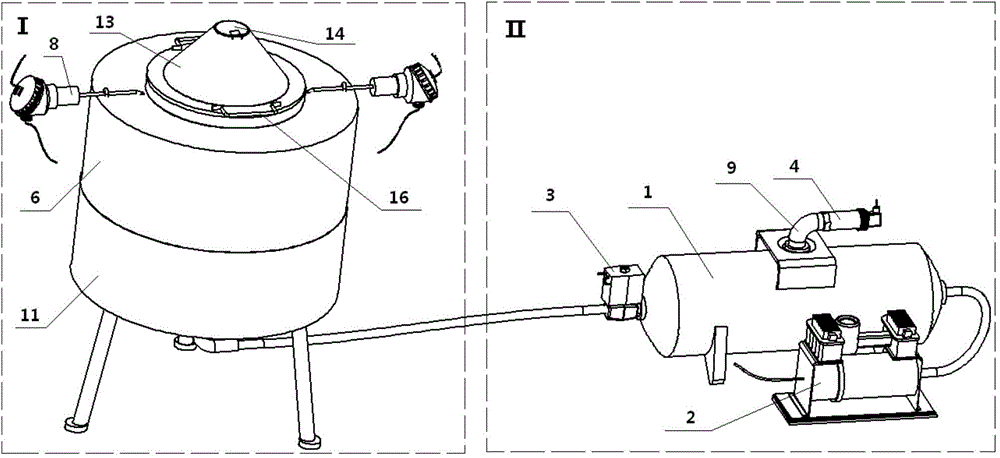

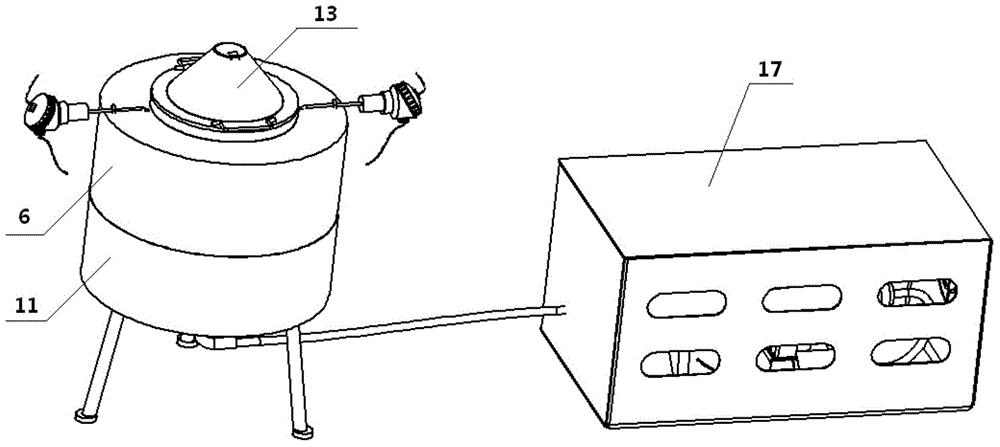

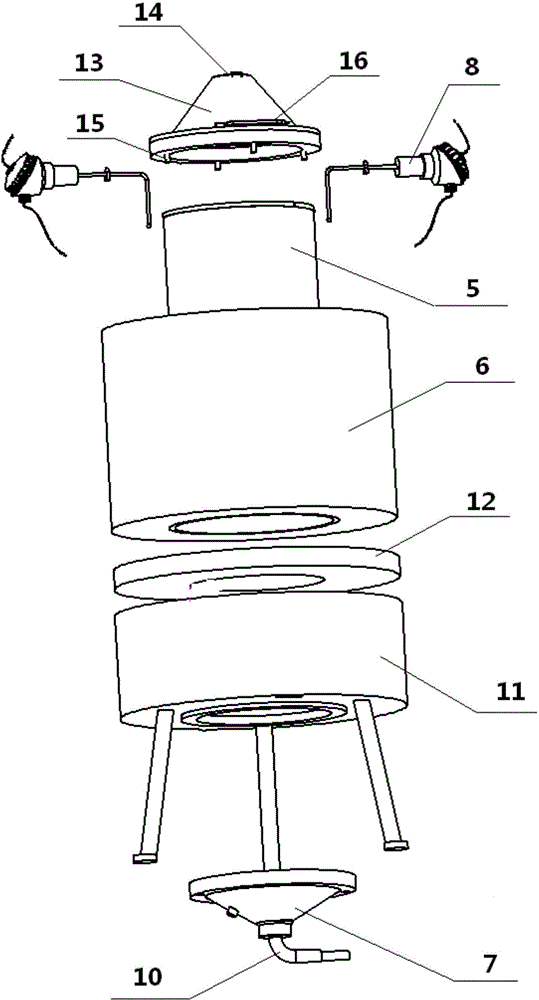

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] see figure 1 , the present invention structurally includes the blowback gas generation part I and the regeneration heating part II of the particle trap; The output end of the particle trap is connected to the regeneration heating part II of the particle trap through the solenoid valve 3; the regeneration heating part II of the particle trap includes a heater 6, and the heater 6 is installed on a base 11 with legs, and the bottom of the heater 6 passes through a disturbance The flow plate 7 is connected to the output end of the gas storage tank 1; the gas storage tank 1 is provided with a pressure transmitter 4 for collecting gas pressure in the tank, and a thermocouple 8 for detecting the heating temperature is installed inside the heater 6; The transmitter 4 and the thermocouple 8 are connected to an external controller, and the output signal of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com