Novel efficient twisting device

A twister and high-efficiency technology, which is applied in the field of air suction and cleaning devices of strip coilers, can solve the problems of short service life and poor wear resistance, and achieve the effects of increasing service life, improving wear resistance and improving twisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below based on the drawings and the embodiments.

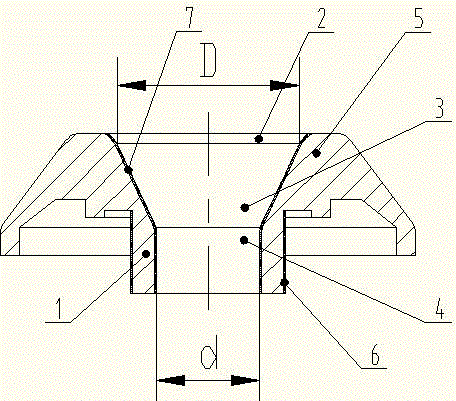

[0014] The new high-efficiency twister shown in the figure includes an upper conical ring 5 and a lower shaft sleeve 1 which are connected as a whole; the conical ring 5 and the shaft sleeve 1 are provided with a yarn top hole 2 from top to bottom. , Twisting hole 3, Twist releasing hole 4; Yarn top hole 2, Twisting hole 3, Twisting hole 4 The hole wall is provided with a wear-resistant layer Ⅰ7, and the outer wall of the sleeve 1 is provided with a wear-resistant layer Ⅱ6; Twisting hole 3 The hole diameter D is twice the hole diameter d of the release hole 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com