A method for hoisting the crankshaft of a mud pump

A hoisting method and mud pump technology, which are applied in the field of oil drilling and production, can solve problems such as unstable hoisting process, difficult assembly, and shift of the center of gravity of the crankshaft, so as to reduce personal injury accidents, shorten the time required for assembly, and reduce the degree of coordination and cooperation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, we will further describe in detail the hoisting method and special tools of the patented mud pump crankshaft of the present invention in conjunction with the accompanying drawings and specific embodiments, in order to understand its structural composition and working mode more clearly, but it cannot be limited by this The protection scope of the patent of the present invention.

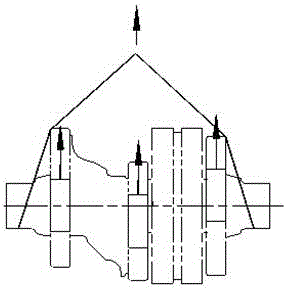

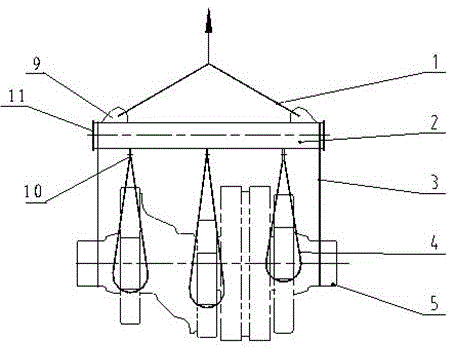

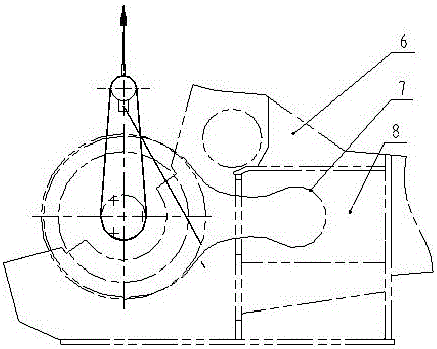

[0026] please see figure 2 with image 3 , before implementing the new method for installing the mud pump crankshaft of the present invention, we first designed and manufactured a special hoisting tool, and its main structure is as follows:

[0027] The hoisting tool for hoisting the mud pump crankshaft of the present invention structurally includes a cylindrical hoisting pipe 2, a main hoisting sling 1, two crankshaft hoisting slings 3 and three crankshaft connecting rod hoisting slings 4. Wherein, the cylindrical hoisting pipe 2 should be thick enough, so as not to be bent and defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com