Clamp formed by welding inclined strut special for lifter

A technology of welding forming and diagonal bracing, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficulty in guaranteeing welding accuracy, inconvenience, and high difficulty coefficient of operation, and achieve accuracy and efficiency High, convenient welding forming, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

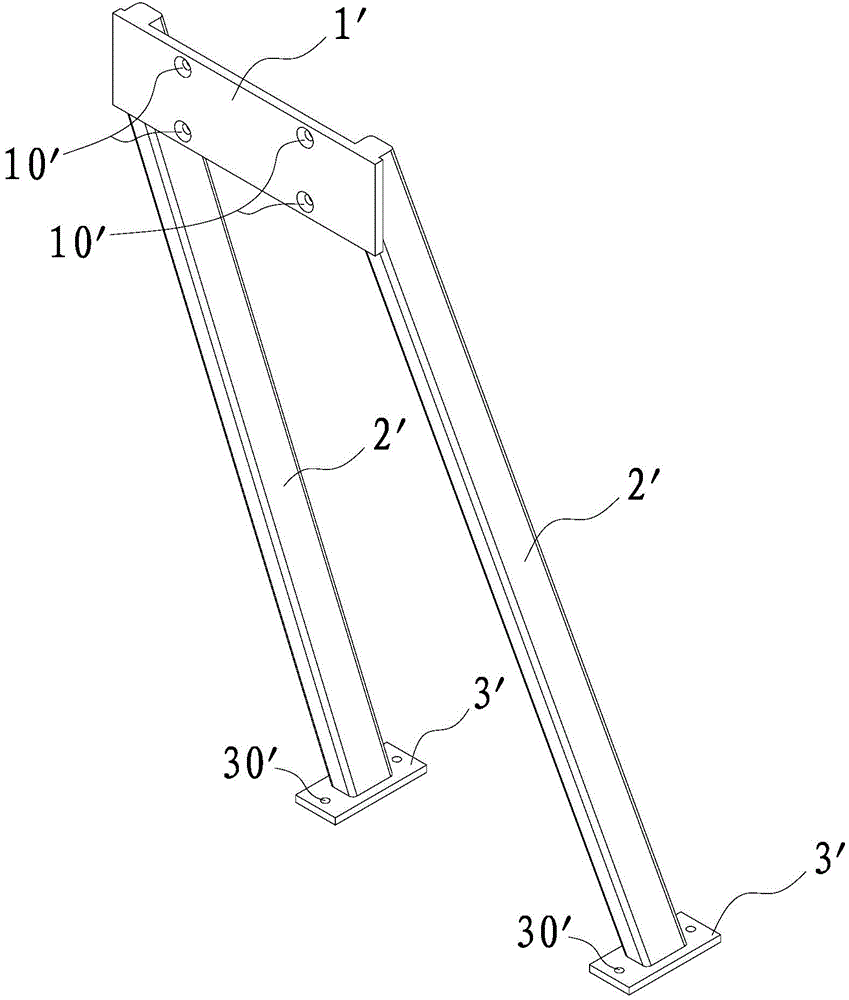

[0028] Such as figure 1 As shown, the diagonal brace includes an upper mounting plate 1' arranged vertically and horizontally, a strut 2' whose upper ends are respectively welded to both ends of the upper mounting plate 1', and respectively welded to the lower end of the strut 2' along the horizontal The lower mounting plate 3' arranged in the direction, wherein the first connecting hole 10' and the second connecting hole 30' are respectively provided on the upper mounting plate 1' and the lower mounting plate 3'.

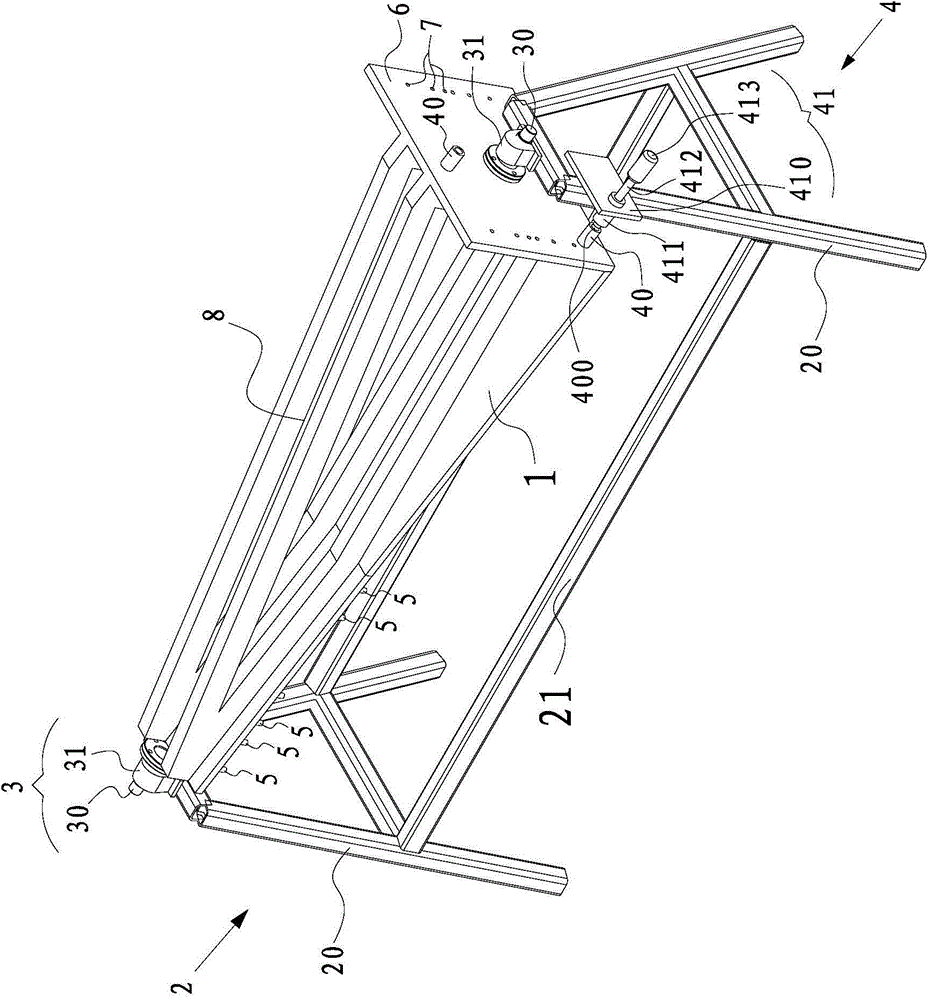

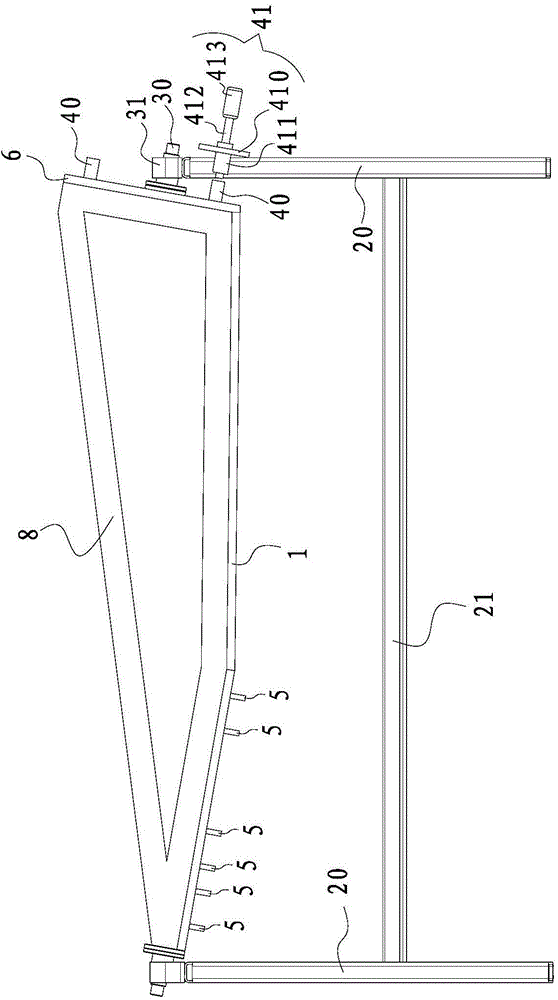

[0029] Such as Figures 1 to 5 As shown, the clamp includes a clamp body 1, a support frame 2 for supporting the clamp body 1, a rotating mechanism 3 arranged on the support frame 2 for rotating the clamp body 1, and a rotating mechanism 3 for connecting the clamp body 1 with the support frame 2. The relatively locked locking mechanism 4, the positioning bolt 5 arranged on the fixture body 1, the positioning template 6 arranged at one end of the fixture body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com