Processing equipment of 5083 aluminium-alloy thin-wall pipes

A technology for processing equipment and thin-walled pipes is applied in the field of processing equipment for 5083 aluminum alloy thin-walled pipes, which can solve the problems of large extrusion coefficient, low production efficiency of aluminum alloy thin-walled pipes, and easy occurrence of stuffy cars, etc. Extrusion coefficient, improve production efficiency, reduce the effect of boring car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide a 5083 aluminum alloy thin-wall pipe processing equipment, which can improve the production efficiency of the 5083 thin-wall pipe.

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

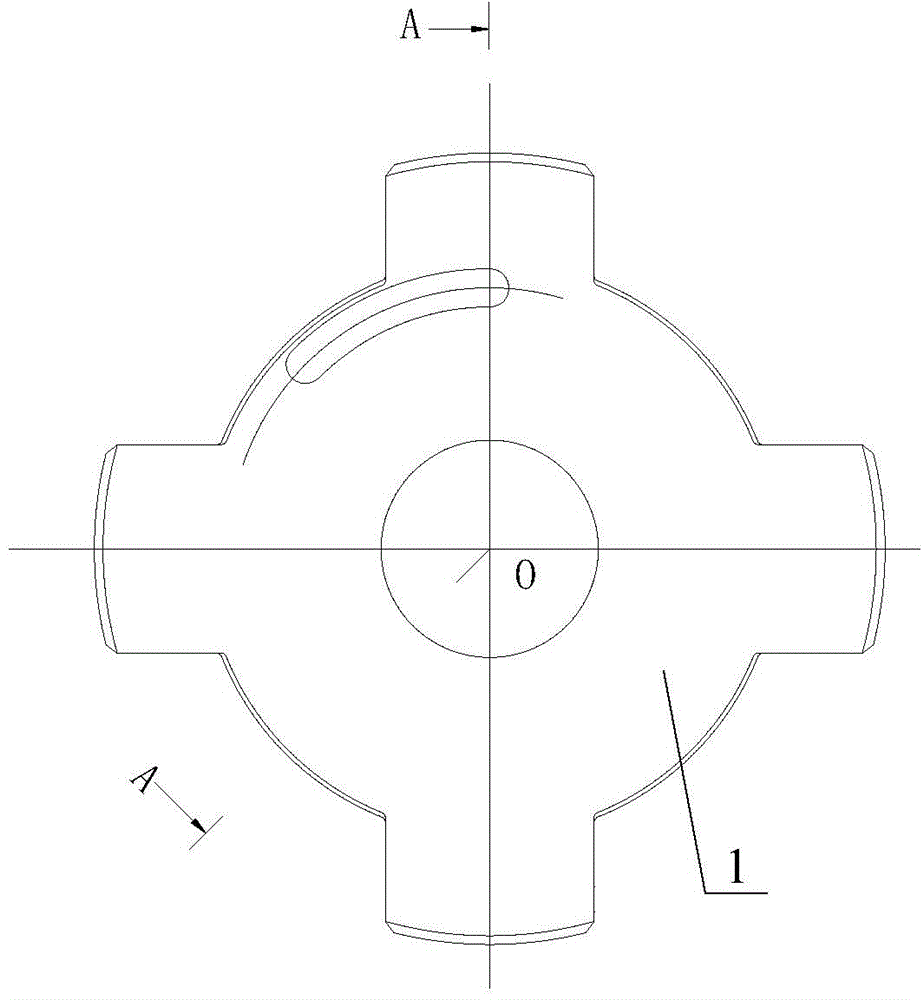

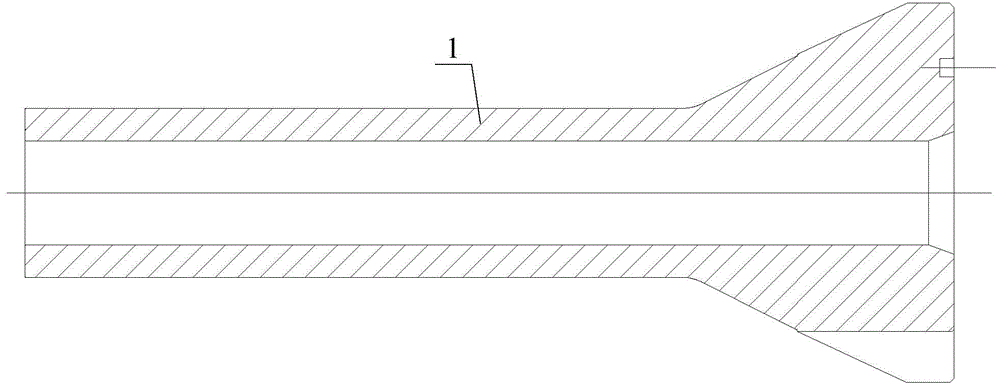

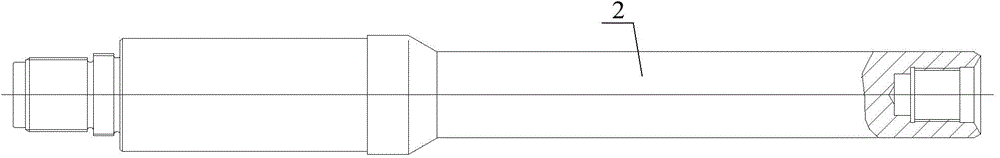

[0024] Please refer to Figure 1 to Figure 8 , in a specific embodiment, the processing equipment of 5083 aluminum alloy thin-walled pipe provided by the present invention includes a cylinder inner sleeve 4, a mold support, a hollow extrusion shaft 1, an extrusion needle 2 and a needle support 3, and the cylinder inner sleeve 4. The inner diameters of the mold support and the hollow extrusion shaft 1 are both 420mm, and the diameters of the extrusion needle 2 and the needle support 3 are 210mm, wherein the diameter of the above-mentioned extrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Large diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com