Electric motor with segmented stator

A motor and stator technology, applied in the field of motors, can solve the problems of cumbersome and complicated installation of motors, and achieve the effects of safe and reliable fixing, low cost, and stable positioning of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

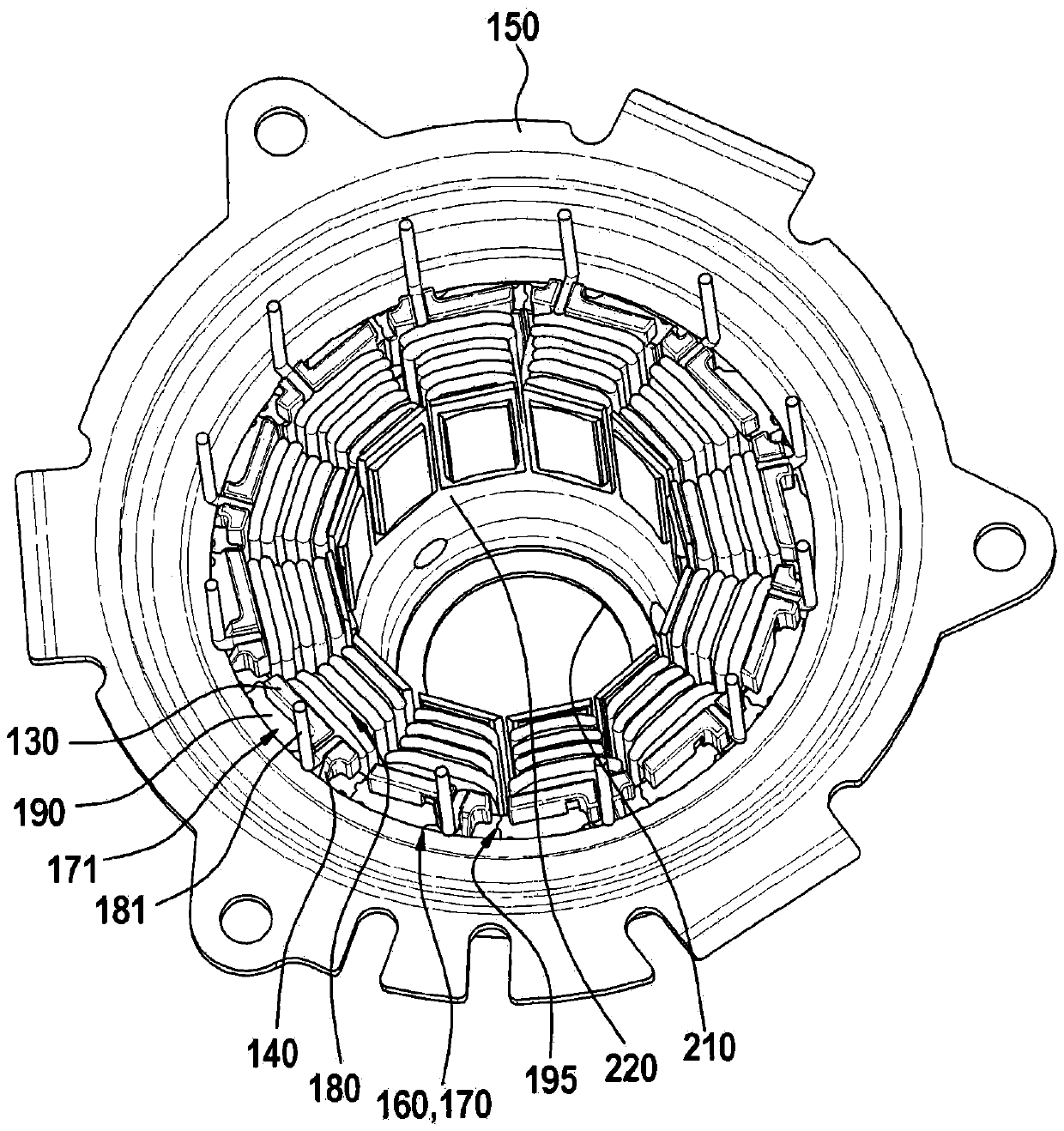

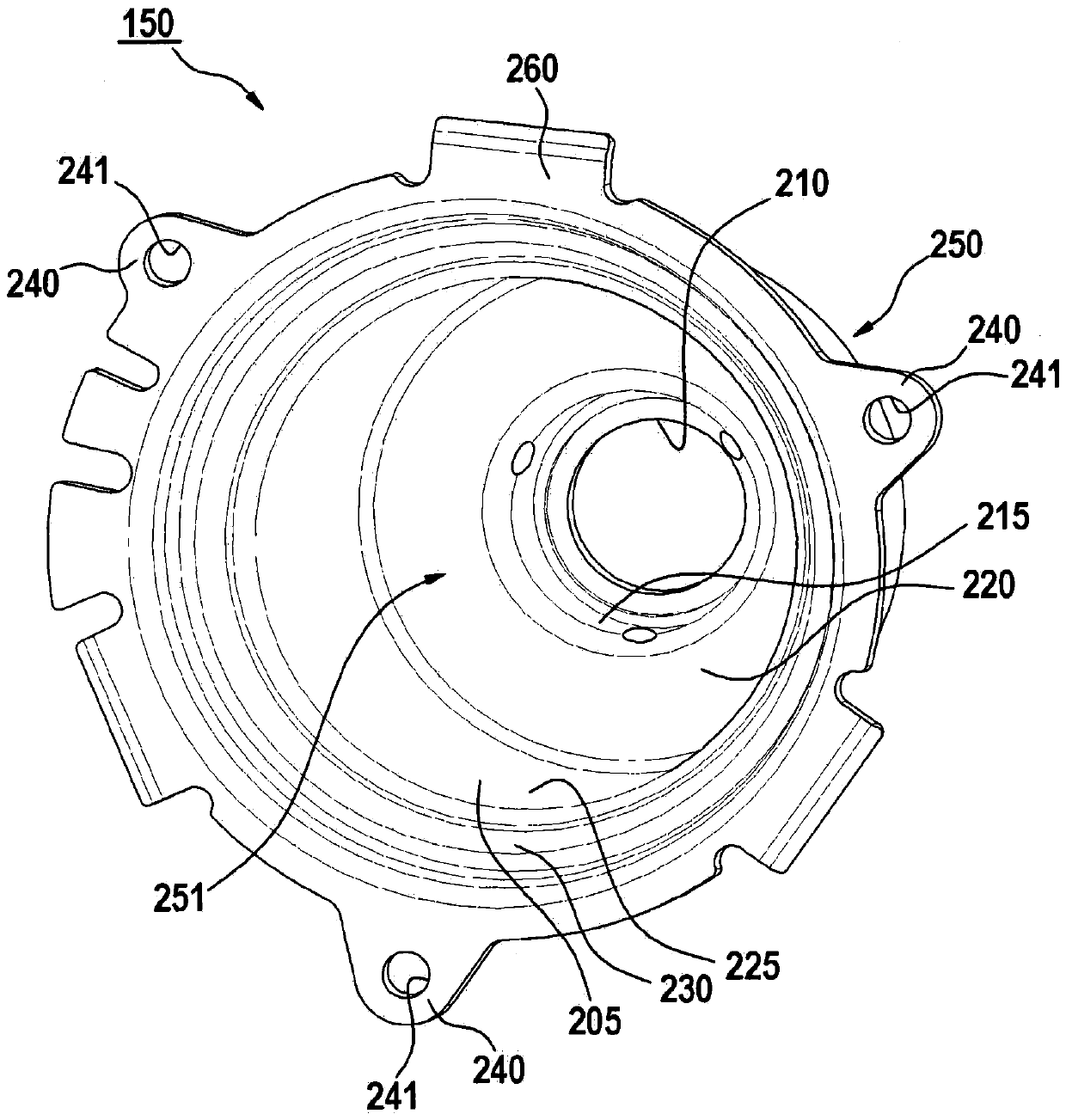

[0036] figure 1 An electric motor 100 , which is embodied as an example as an inner rotor motor, is shown, having an inner rotor 110 arranged on a motor shaft 120 and a segmented outer stator 160 , which are illustratively arranged in a housing 150 . According to one embodiment, the segmented outer stator 160 has a plurality 170 of annularly arranged stator segments, illustratively twelve stator segments. The twelve stator segments are preferably designed in such a way that they can be joined together annularly, wherein the respective adjacent stator segments in the circumferential direction of the outer stator 160 or the housing 150 are preferably positively connected to each other or fixed to each other, for example by means of A suitable groove-lug-connection 195 is realized. In particular, the twelve stator segments are preferably formed at least substantially identically. Therefore, for reasons of simplicity and clarity of illustration, only one individual stator segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com