Multi-target optimization method for numerical control machining technological parameters facing energy efficiency

A multi-objective optimization and processing technology technology, which is applied in the field of process parameter optimization related to energy efficiency in CNC machining, and can solve problems such as improper selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

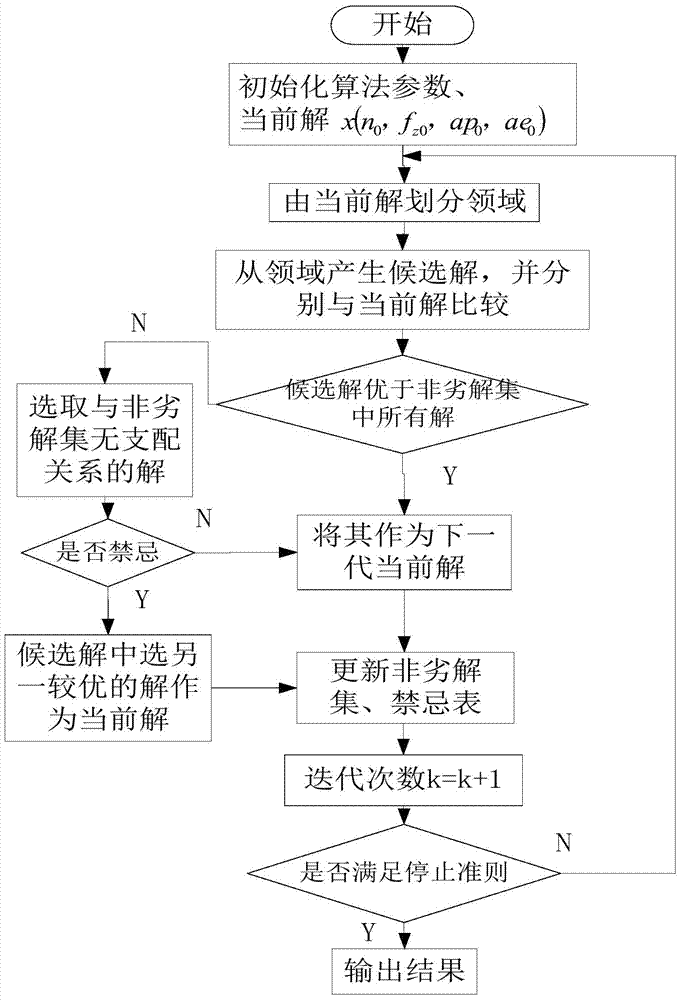

Method used

Image

Examples

Embodiment

[0029] In this embodiment, a company's CNC500 five-axis linkage machine tool is used as the platform, and the following The milling size of the cemented carbide integral milling cutter is 150×100 square steel surface, and the machine tool energy efficiency monitoring system independently developed by the applicant is used to measure the real-time power of the CNC machine tool. The experimental conditions mainly include machine tool conditions, tool conditions, etc., as follows:

[0030] (1) Machine tool conditions

[0031] Table 1 Machine tool models and their parameters

[0032]

[0033] Include the following steps:

[0034] 1) Set the spindle speed of CNC machining as n and the feed per tooth as f z , the amount of back cut is a p , and the amount of side cut is a e ;

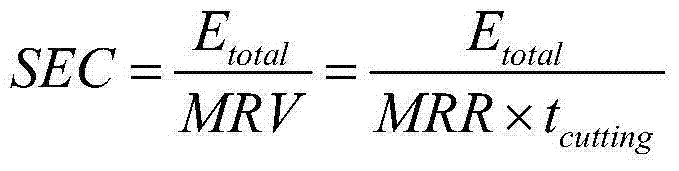

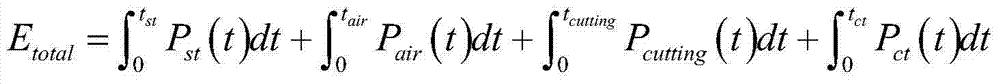

[0035] 2) Establish a multi-objective optimization model for NC machining process parameters:

[0036] minF(n, f v , a p , a e ) = (minSEC, minT p );

[0037] Among them, T p = t st +t air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com