Device and method for determining positions of strip steel surface defect

A defect location and strip steel technology, applied in the field of strip defect detection equipment, can solve problems such as rising cost of automobile sheet products, full-length surface quality inspection of steel coils, and low production capacity of automobile sheet production lines, so as to avoid missed inspections and improve inspection The effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The device and method for determining the location of steel strip surface defects according to the present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments, but the explanation and description do not constitute improper limitations on the technical solution of the present invention.

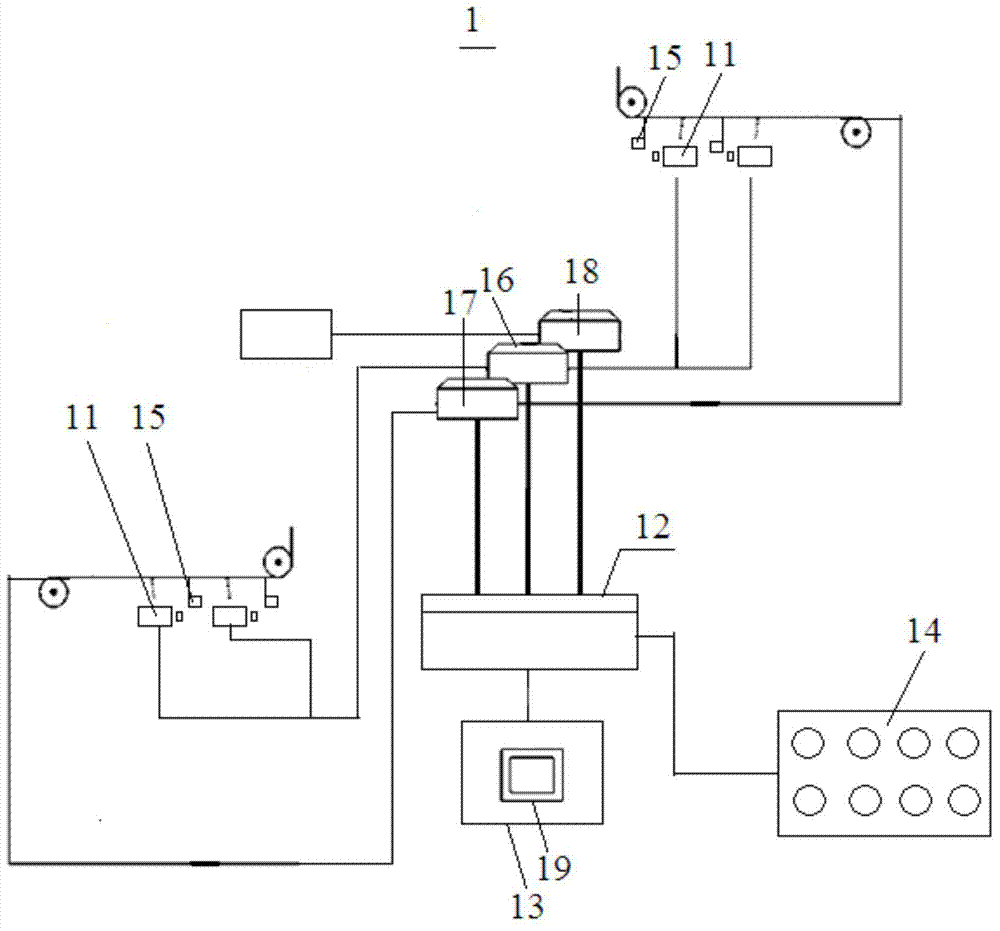

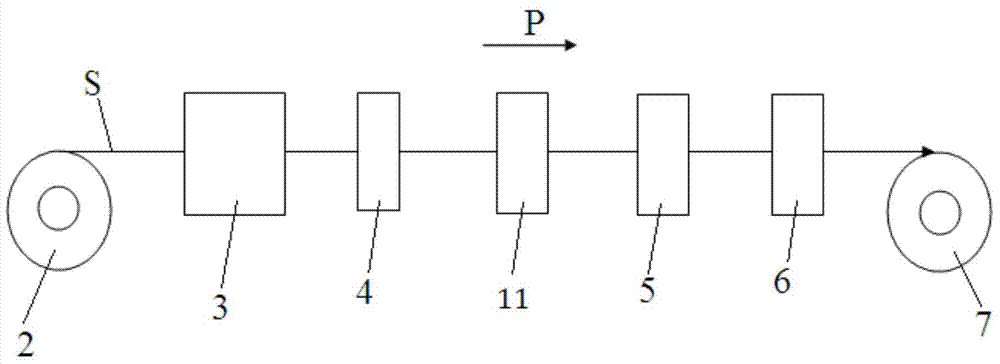

[0065] figure 1 shows the structure of the device for determining the position of the surface defect of the strip according to the present invention in one embodiment, and figure 2 It shows the state that the strip steel surface image acquisition device in the device is installed on the actual production line.

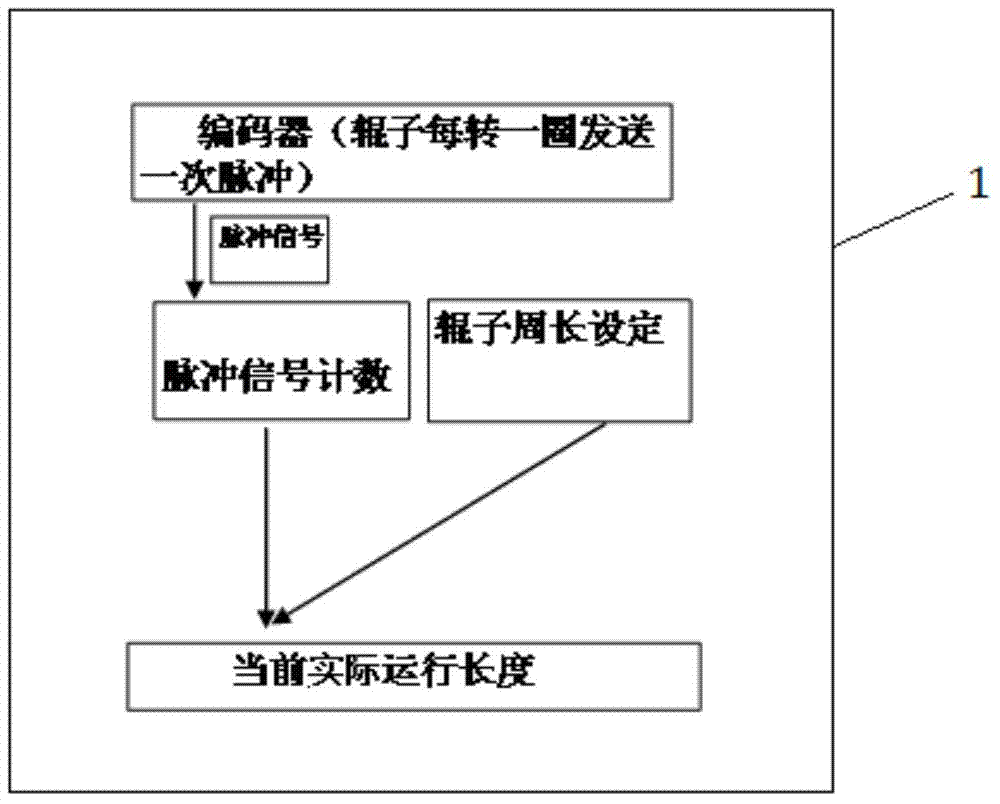

[0066] Such as figure 1 with figure 2As shown, the device 1 for determining the position of the strip surface defect in this embodiment includes a strip surface image acquisition device 11, a server 12, a workstation 13, an alarm device 14, an encoder 15, a first data receiver 16, a second A data rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com