Making and production process for animal and plant type organic fertilizer

An organic fertilizer and production process technology, applied in the field of animal and plant type organic fertilizer production and production process, can solve the problems of easily causing diseases and insect pests, increasing the critical point of nutrient elements on crop fertilizer efficiency, defertilizing and damaging crop roots, etc. And the effects of regulating crop growth, enhancing immunity and stress resistance, and inhibiting the reproduction of harmful pathogens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The production and production process of animal and plant-type organic fertilizers, the preparation methods include animal fertilizer preparation methods, plant fertilizer preparation methods, and organic fertilizer preparation methods are as follows:

[0048] S1: Dry (or dry) the starter and the measured animal raw materials under the action of a planer to produce animal fertilizer;

[0049] S2: Drying (or drying) the starter and the metered plant raw materials under the action of a planer, and then drying (or drying), the plant fertilizer can be obtained;

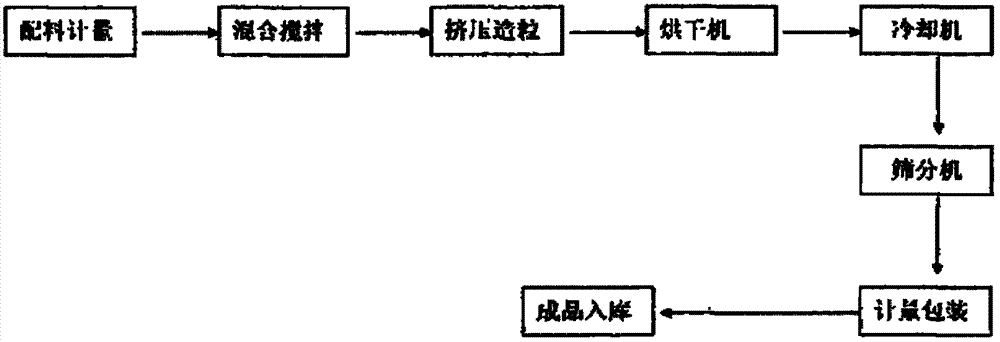

[0050] S3: After mixing and stirring S1 and S2, the organic fertilizer is produced by extrusion granulation, polishing, drying, cooling, sieving, metering, packaging, etc.

[0051] The animal raw materials and plant raw materials mentioned in the preparation methods of S1 and S2 all use organic raw materials without residues of diseases and insect pests; select organic raw materials with high purity and few impurit...

Embodiment 2

[0065] Peanut comparison test:

[0066] Cultivated land, use machine fertilizer 40kg of the present invention.

[0067] Sow peanut seeds, and use 20kg of compound fertilizer (Stanley 15-15-15) at the same time.

[0068] Harvest, yield 1025 jins. In the control test, 50kg of 15-15-15 compound fertilizer was used, and the output was 816 catties.

[0069] Using the organic fertilizer of the invention: the fruit tastes good, the fruit is plump, and the plant has strong lodging resistance.

Embodiment 3

[0071]Ginger comparative test:

[0072] 1. How to use:

[0073] A, basal fertilizer: tillage, use organic fertilizer 120kg of the present invention.

[0074] B, kind of manure: plant big ginger, furrow applies organic fertilizer 20kg of the present invention, compound fertilizer 20kg.

[0075] C. Top dressing:

[0076] For the first time, topdress 50kg (organic fertilizer: inorganic fertilizer = 2:1)

[0077] For the second time, topdress 80kg (organic fertilizer: inorganic fertilizer = 2:1)

[0078] For the third time, topdress 100kg (organic fertilizer: inorganic fertilizer = 2:1), cultivate soil, and wait for harvest.

[0079] The organic fertilizer is: 6-2-4, the compound fertilizer is Aobao 15-15-15, and the control test: no organic fertilizer is used, all compound fertilizers are used in the same amount as above.

[0080] Harvest: The yield of using organic fertilizer is 12,348 catties, which is 8.6% higher than that of pure compound fertilizer, and the pests and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com