Large-sized pressure spring loading and unloading machine

A pressure spring, a large-scale technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor safety and low work efficiency, and achieve the effects of reducing wear, increasing loading and unloading speed, and high-efficiency compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

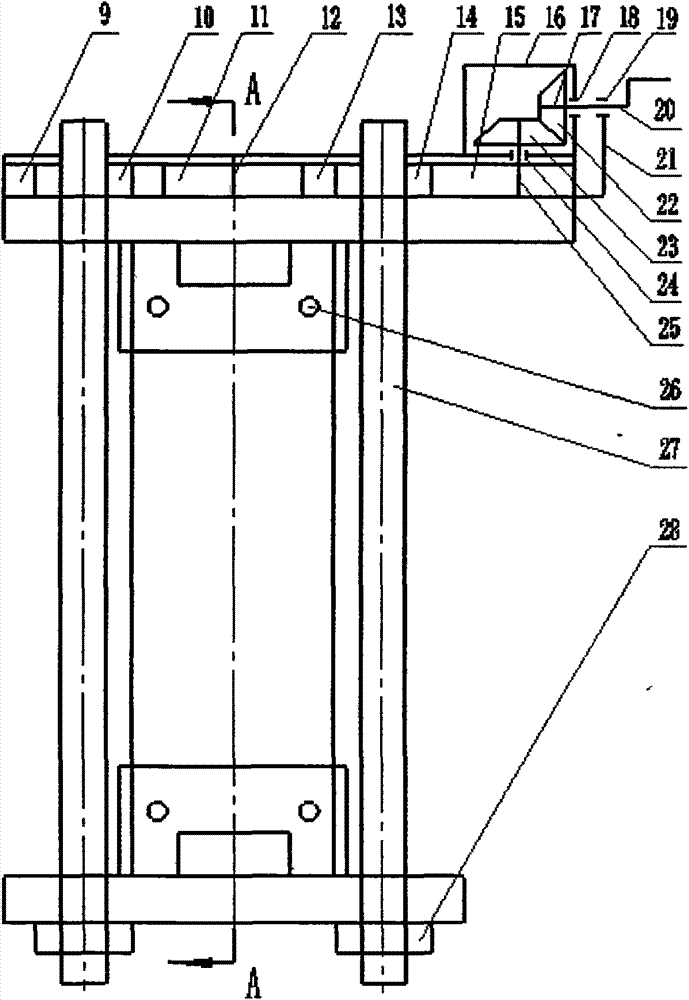

[0012] A large-scale pressure spring loading and unloading machine, as shown in the accompanying drawings, it consists of a left screw column shaft 1, an upper solid spring seat 2, a wear-resistant lining 3, an upper push spring support plate 4, a tension spring plate combination 5, and a spring 6 , push down spring support plate 7, lower solid spring seat 8, left lead screw gear 9, left lead screw nut 10, intermediate gear 11, intermediate gear shaft 12, right lead screw gear 13, right lead screw nut 14, driving gear 15 , gearbox case 16, driving bevel gear shaft 17, main bevel gear shaft bearing 18, rocker bearing combination 19, rocker 20, rocker bracket 21, driving bevel gear 22, driven bevel gear 23, driven bevel gear shaft Bearing 24, driven bevel gear shaft 25, extension spring plate nut 26, right lead screw column shaft 27, nut 28, extension spring plate 5-1, extension spring hook 5-2, extension spring hook nut 5-3 form. The left screw column shaft 1 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com