A pneumatic crimping tool for flag-shaped connecting pieces

A connecting piece and tooling technology, which is applied in the field of pneumatic crimping tooling, can solve problems such as the insertion of the insert is not in place, the insertion is not tight, and the fingers are swollen and deformed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiment:

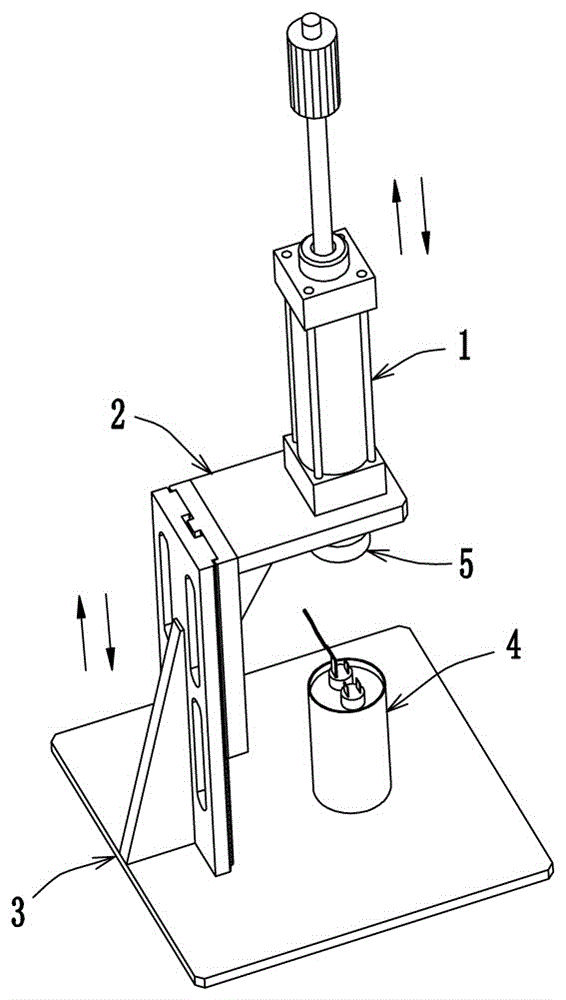

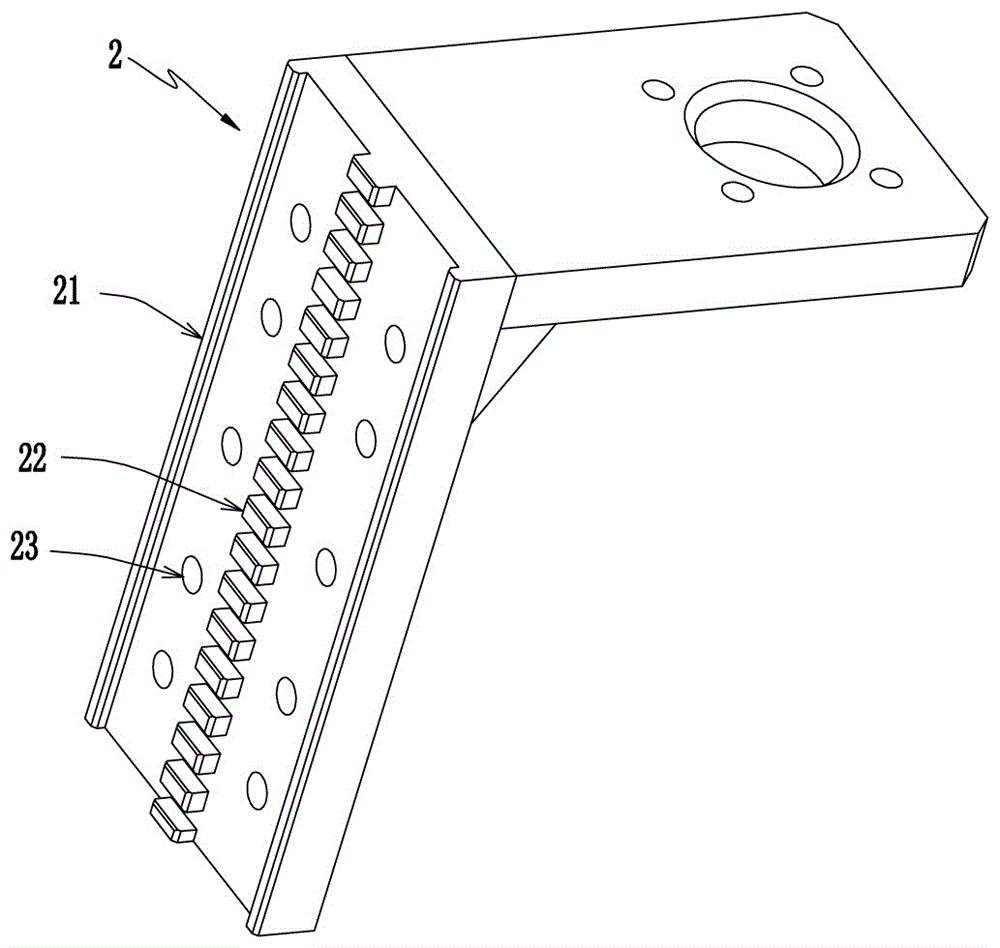

[0014] See attached Figures 1 to 3 As shown, a pneumatic crimping tool for the flag-shaped connecting piece described in this embodiment includes a fixing seat 3, a connecting seat 2 that can be adjusted in the vertical direction with the fixing seat 3, and is fixed on the connecting seat 3. The driving cylinder 1 on the seat 2, the creasing die head 5 driven by the driving cylinder 1 and the foot valve (not shown in the figure) for controlling the telescopic movement of the driving cylinder 1 .

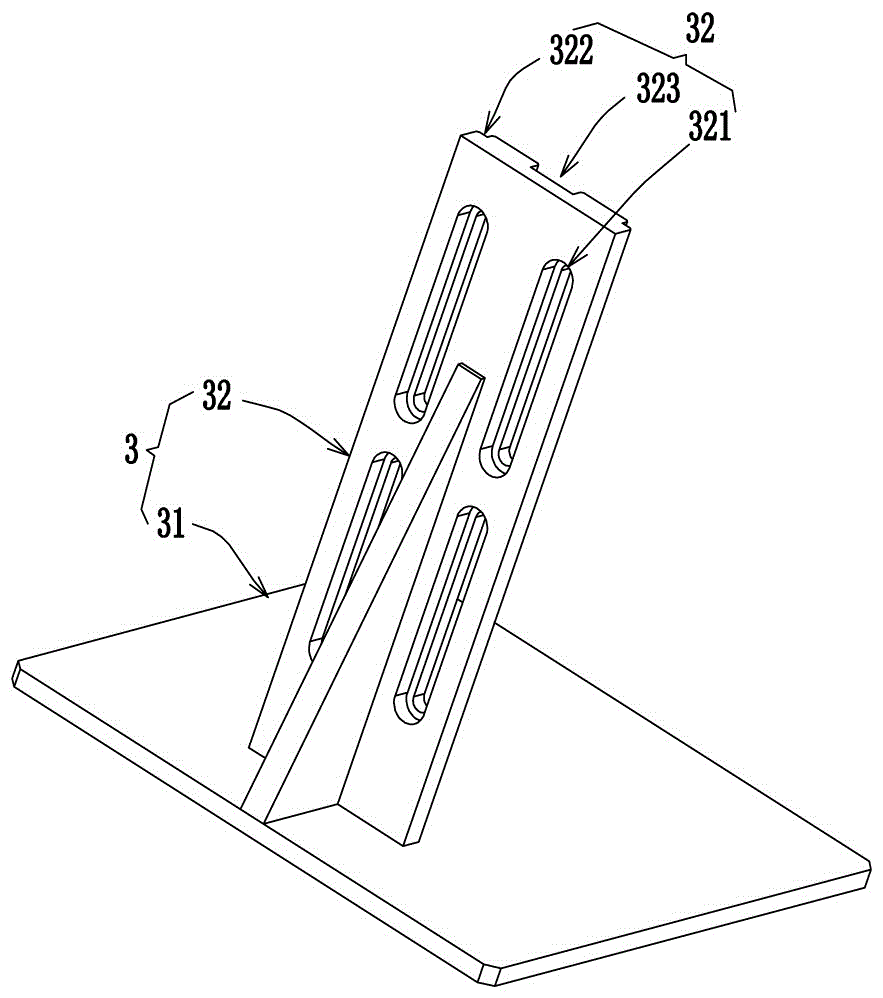

[0015] See attached figure 1 and 3 As shown, in order to make the entire crimping tool take up less space and facilitate the operator’s operation, the above-mentioned fixing seat 3 in this solution includes a workbench 31 for placing the workpiece 4 and a vertical connection fixedly connected to one side of the workbench 31 plate 32. At the same time, in order to make the whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com