Waste circuit board disassembling machine

A technology for waste circuit boards and circuit boards, which is applied in the direction of electronic waste recycling, solid waste removal, and tool manufacturing, and can solve problems such as unsatisfactory effects, polluted gas, and damage to electronic components, and achieve low dismantling costs. The effect of less pollutant discharge and lower component damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in combination with specific embodiments.

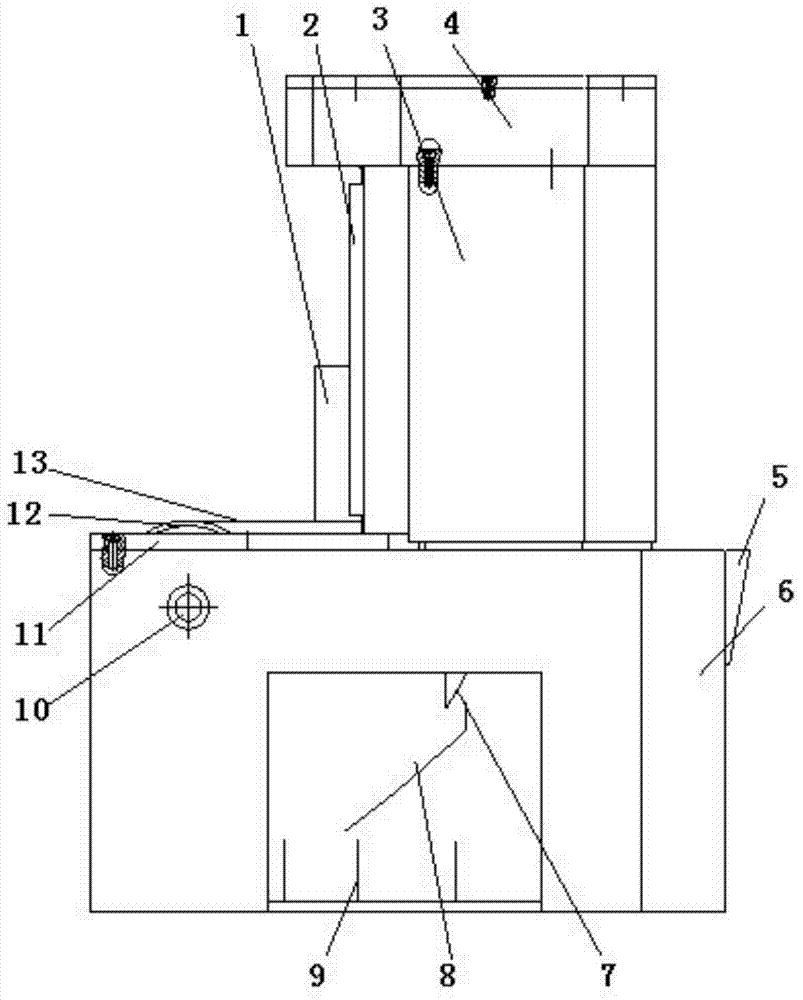

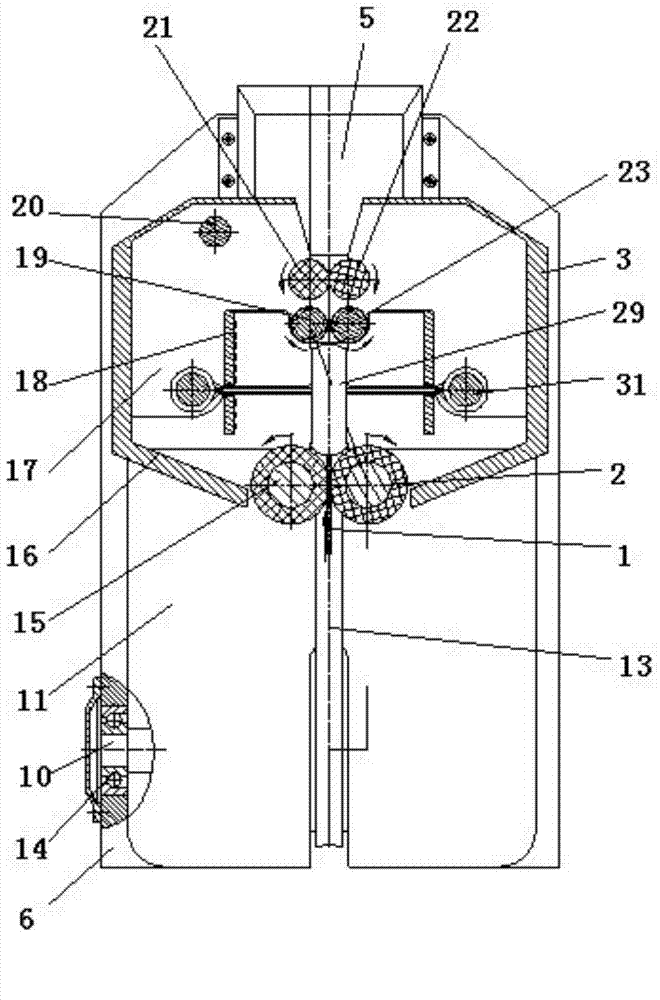

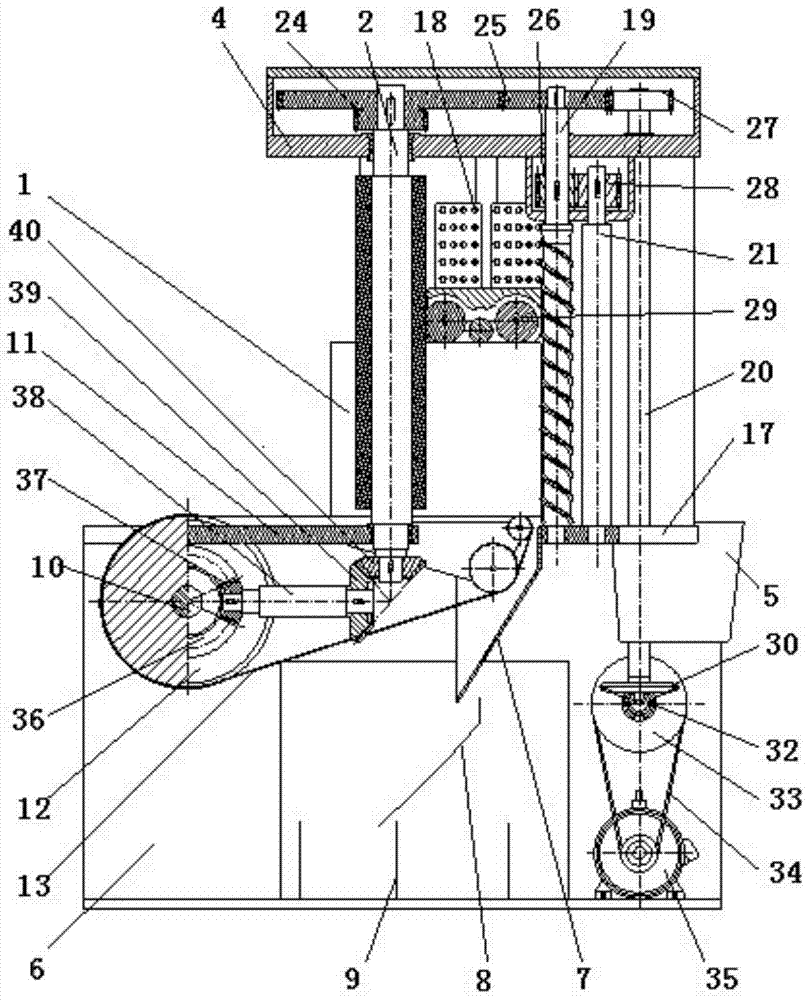

[0017] The high-efficiency and energy-saving waste circuit board dismantling machine of the present invention is mainly a device for dismantling electronic components on the waste circuit board. Such as Figures 1 to 3 As shown, the right rubber roller shaft 2 and the left rubber roller shaft 15 are included, and the upper ends of the right rubber roller shaft 2 and the left rubber roller shaft 15 are connected with the spur double gear 24, and the straight tooth double gear 24 is connected with the first straight gear 25 , the upper end of the left-handed roller knife 19 and the right-handed roller knife 23 is connected to the first spur gear 25, the first spur gear 25 is connected to the third spur gear 27, the upper end of the first transmission shaft 20 is connected to the third spur gear 27, and the spur gear 24 , the first spur gear 25 and the third spur gear 27 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com