Synchronous plasma degreasing film device on plastic bottle surface

A technology of plasma and plastic bottles, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as explosions, gas leakage, and reduction of the efficiency of spraying and coding operations for removing oil film on the surface of plastic bottles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further illustrated by specific examples below.

[0025] The present invention is further illustrated by specific examples below.

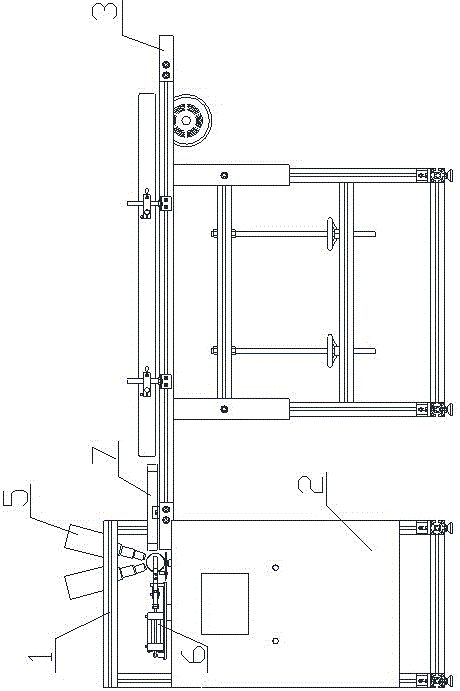

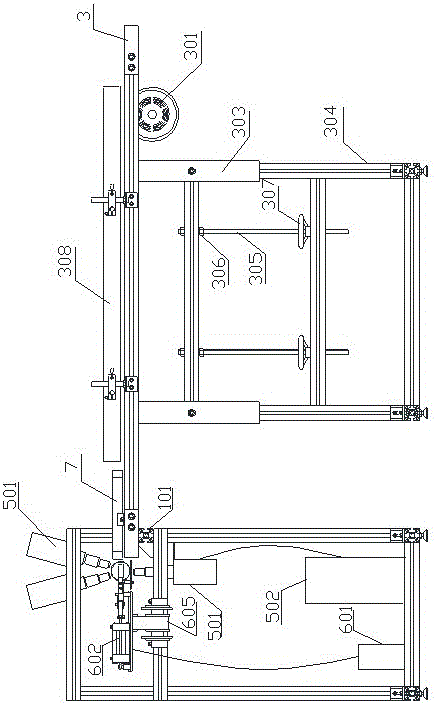

[0026] like figure 1 , image 3 As shown in the figure, a synchronous plasma degreasing film device on the surface of a plastic bottle; it includes a base frame 1 for installing each module, a control module 2 for controlling the overall action of the device, a feeding conveying device 3 for conveying raw materials, and a discharging device The conveying device 4 ; the plasma bombardment device 5 for removing the oil film on the surface of the plastic bottle, and the bottle grabbing device 6 for grabbing the plastic bottle body 10 .

[0027] like figure 1 , figure 2 and image 3 As shown, the feeding conveying device 3 includes a feeding conveying frame, an upper bracket 303 and a lower base 304 that adjust the height of the feeding conveying frame and are connected in a socket structure, and a motor provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com