Preparation method of composite anti-blocking suction pipe

A composite straw technology, which is applied to tableware, household appliances, tableware, etc., can solve the problems of consumers who are difficult to absorb liquids, and absorb liquids, and achieve the effect of high efficiency and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

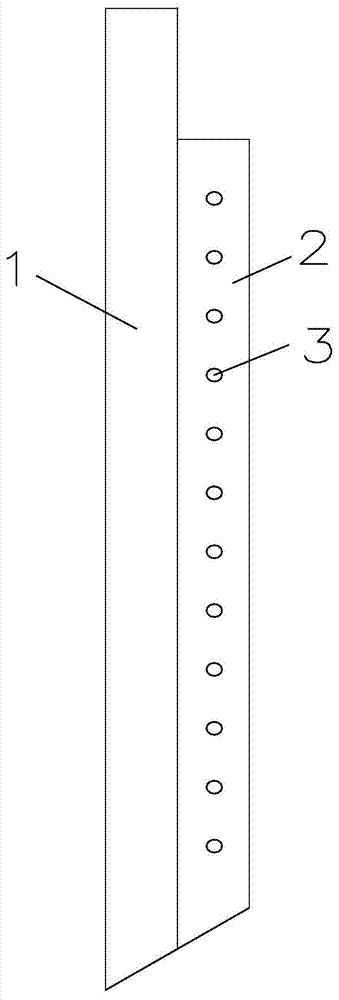

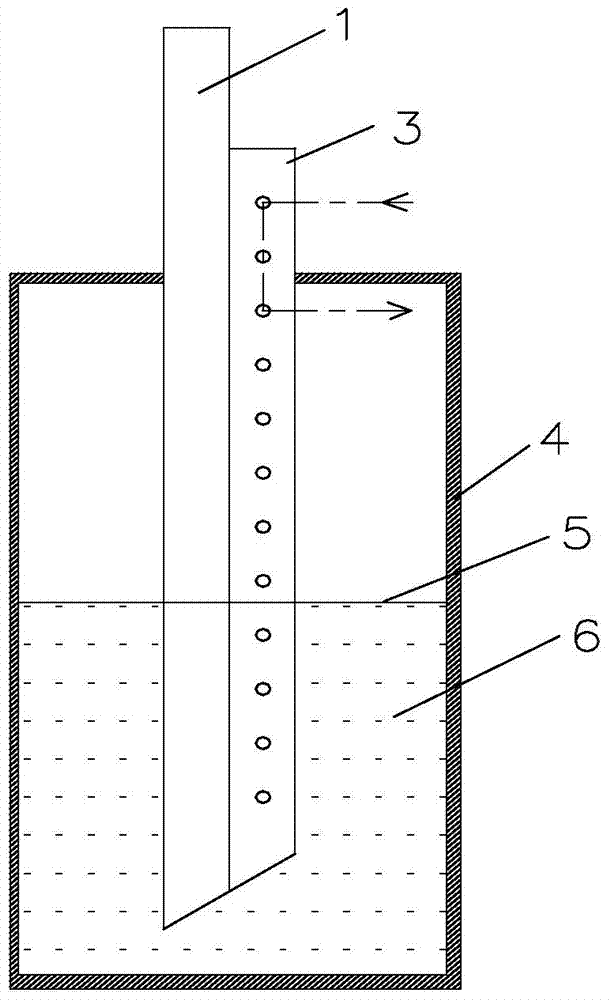

[0031] Embodiment 1: as Figure 1-4 , a kind of preparation method of composite anti-blocking straw, is characterized in that, comprises the following steps:

[0032] Step 1: prepare the main pipe 1 and the auxiliary pipe 2;

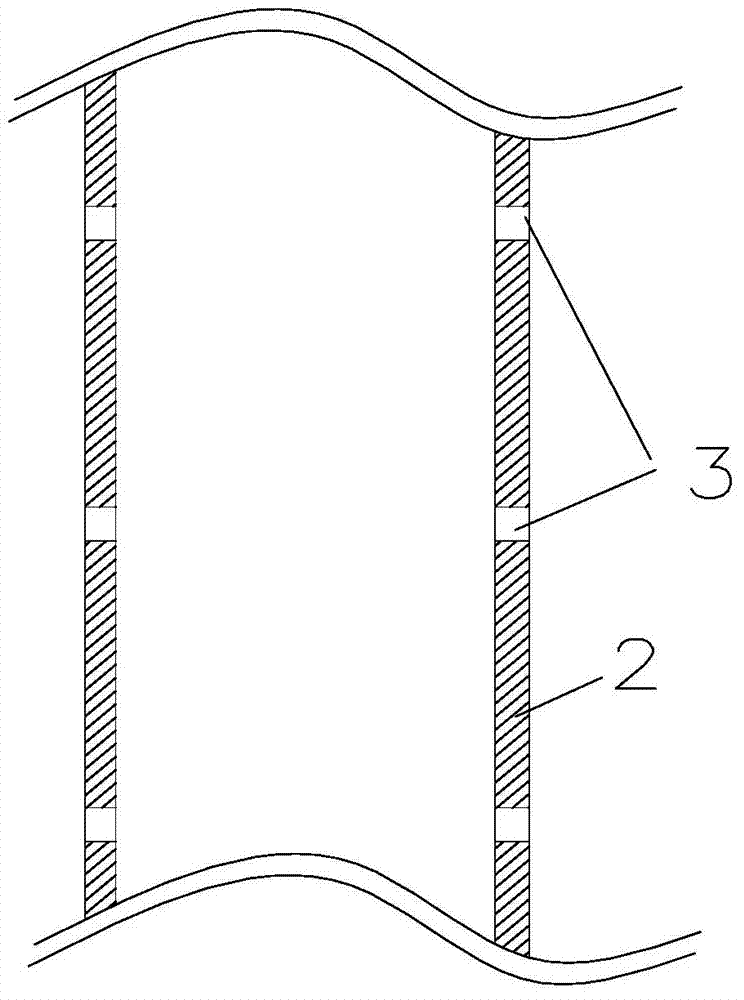

[0033] The process of preparing the auxiliary pipe is: opening at least one row of ventilation holes 3 along the axis direction of the pipe body under the pipe wall of the pipe body; each row of ventilation holes includes a plurality of ventilation holes; the length of the auxiliary pipe is smaller than the length of the main pipe;

[0034] Step 2: Apply glue on the outer wall of the main pipe or the auxiliary pipe, and glue the main pipe and the auxiliary pipe side by side; and the lower ends of the main pipe and the auxiliary pipe are flush, and the top of the main pipe is higher than the top of the auxiliary pipe;

[0035] Step 3: Cut off the lower section of the bonded main pipe and auxiliary pipe obliquely to form an oblique incision.

[0036] A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com