Abrasive grain containing a first face without vertices and a second face with vertices

A technology of abrasive grains and base surfaces, which is applied in the direction of abrasives, manufacturing tools, and other chemical processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

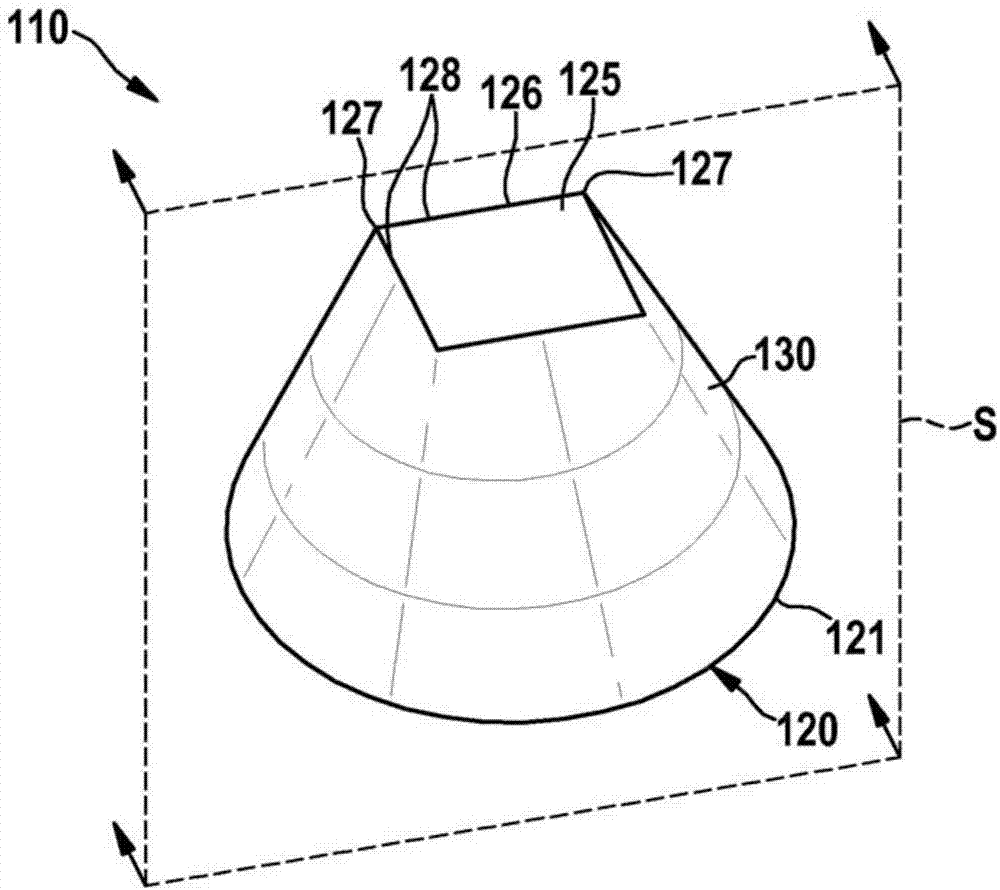

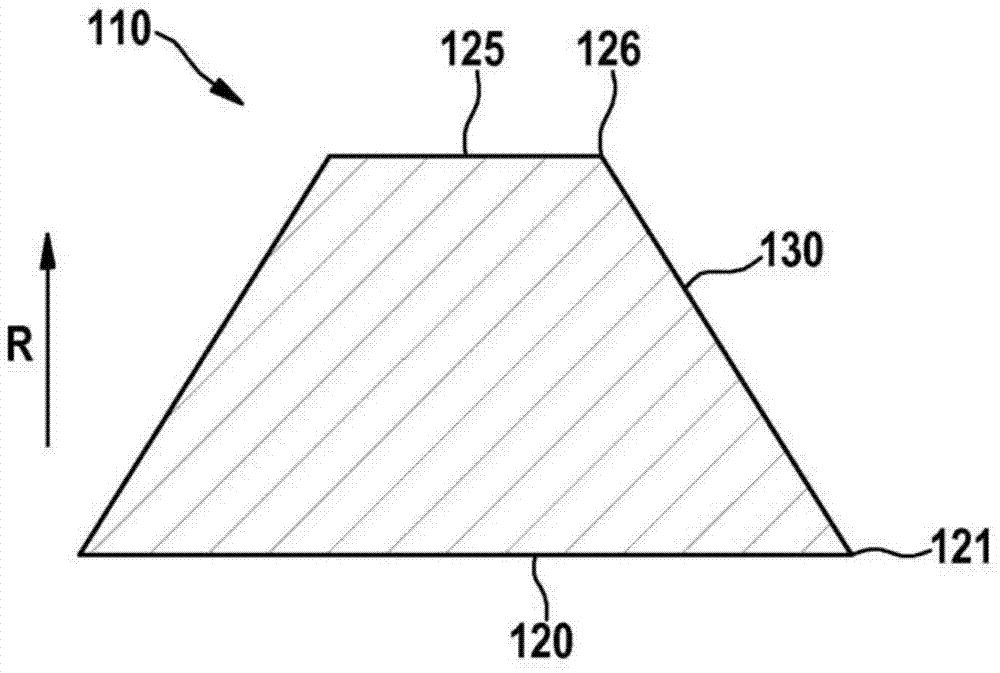

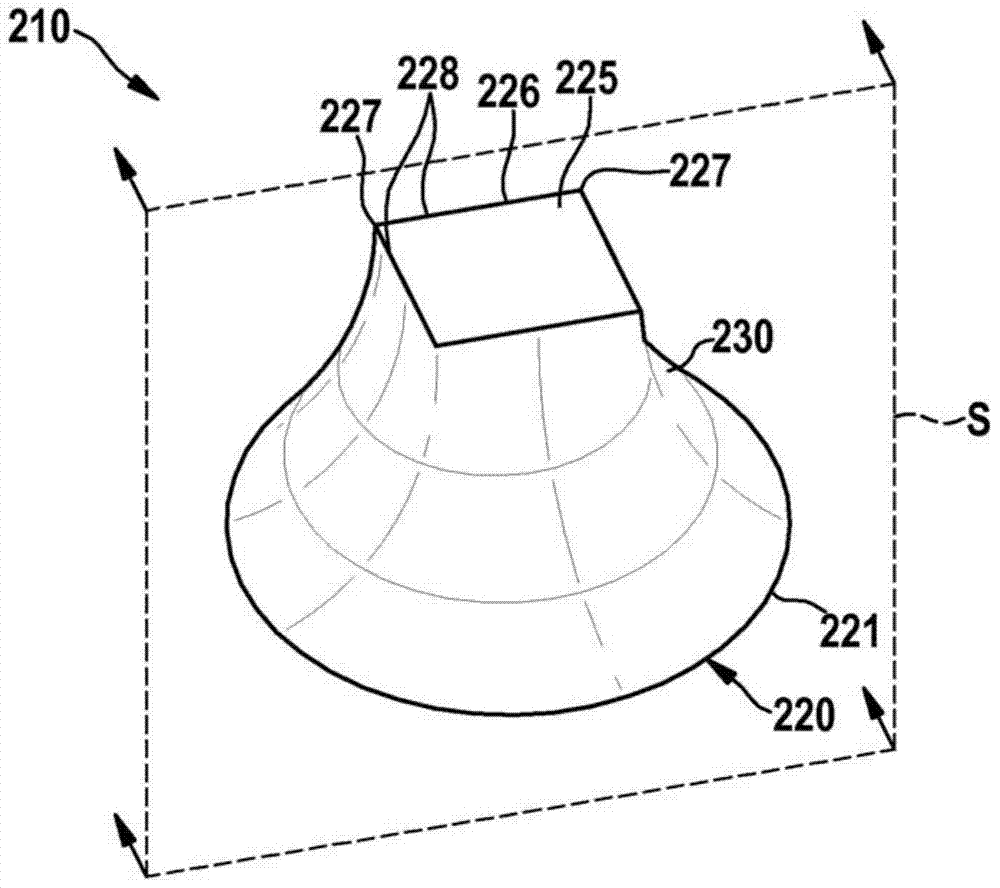

[0324] The abrasive particle 110 shown in the perspective view of Figure Ala comprises a flat circular first face 120 and a square (i.e. polygonal) second face 125 parallel thereto, the first face having a first outer surface. profile 121 , the second surface has a second outer profile 126 . An arcuate peripheral surface 130 is formed between the first surface 120 and the second surface 125 . The lines marked on the peripheral surface 130 indicate the arcuate course of the peripheral surface 130 ; however, the lines are not actual edges of the abrasive grains 110 . Abrasive grain 110 extends entirely between two planes defined by first face 120 and second face 125 .

[0325] The first outer contour 121 has no corners, since the directions of the tangents at the points of the first outer contour 121 run continuously. The absence of corners in the first outer contour 121 contributes to the reliable fastening of the abrasive grains 110 with the primer. Compared to the first ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com