On-board flywheel energy storage device

A technology of flywheel energy storage and flywheel, which is applied in the direction of electromechanical devices, control mechanical energy, electrical components, etc., can solve the problems of mechanical system complexity and increased manufacturing costs, and achieve the effects of improved energy utilization, convenient maintenance, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

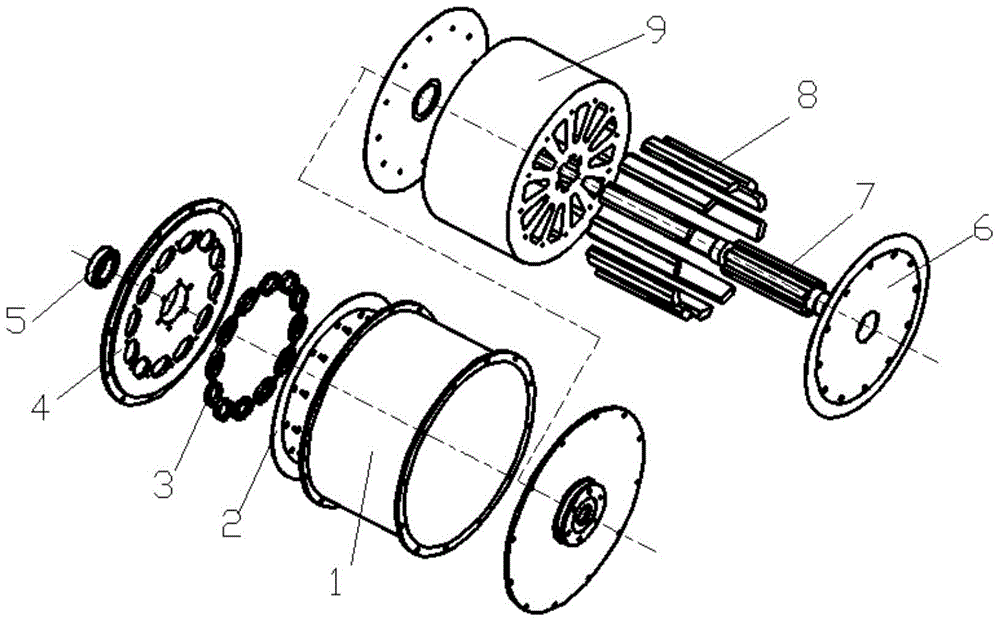

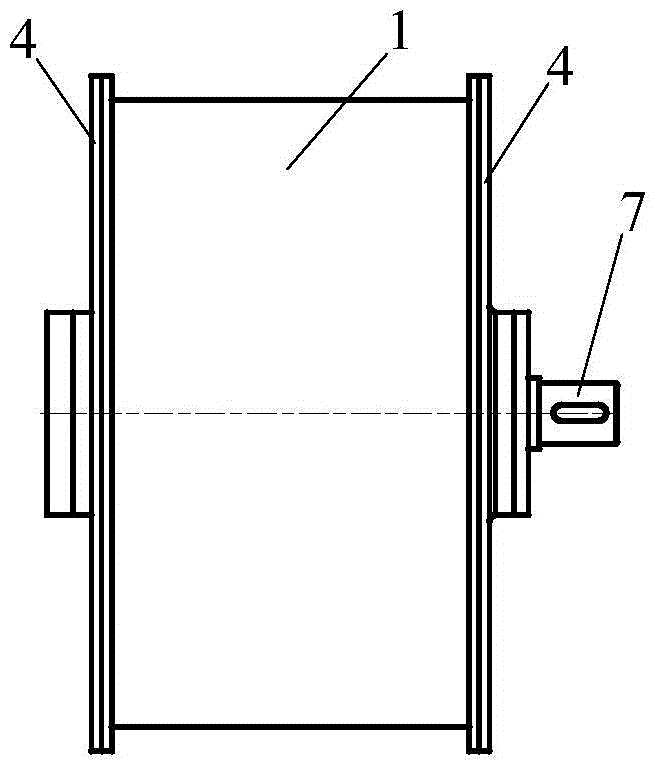

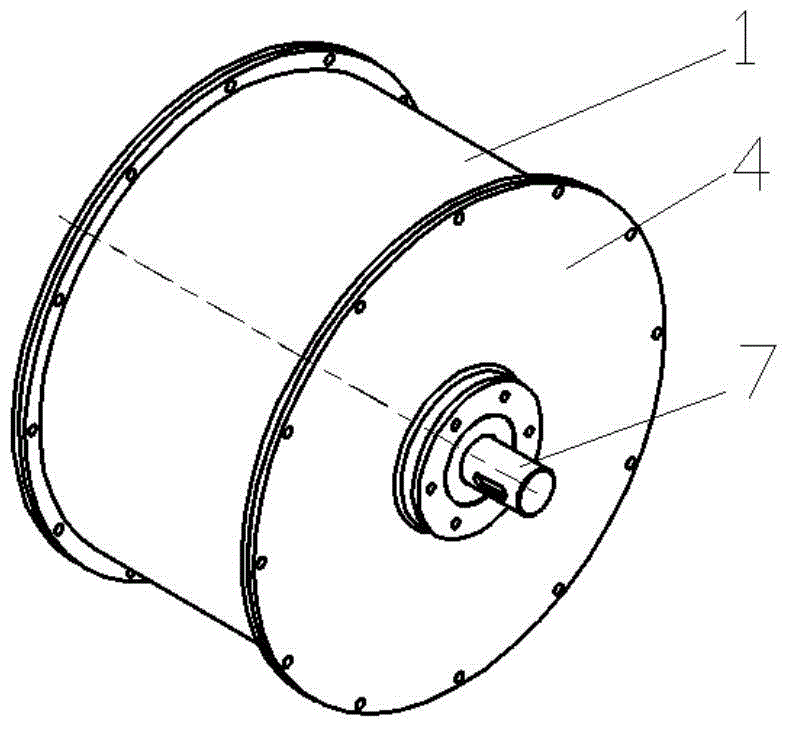

[0020] combine Figure 1-7 , the present invention mainly uses the short-term energy storage of the flywheel and recycles the braking energy in the form of mechanical energy. At the same time, it directly converts the braking energy converted into electrical energy and stored. The functions of the present invention are mainly realized by the following structures.

[0021] 1. Flywheel assembly (add power generation device)

[0022] The flywheel assembly consists of a flywheel rotor, a bar magnet, a flywheel shaft and a flywheel end cover. Bar magnets of different polarities are uniformly distributed in the gap of the flywheel rotor hub, and the bar magnets are positioned and installed through the upper top surface and the V-shaped face of the flywheel rotor hub gap. A spline shaft is installed in the middle of the flywheel rotor, and its function is to convert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com