Construction method for taper-changeable composite fiber winding models

A composite fiber and construction method technology is applied in the field of construction of a three-dimensional model of a composite fiber variable taper winding product to achieve the effects of improving design efficiency, simplifying the design process, and being supported by good data and logical relationships.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

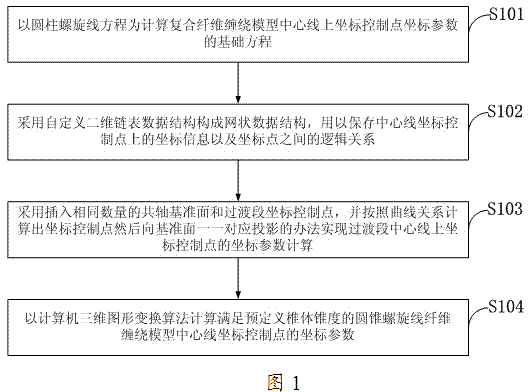

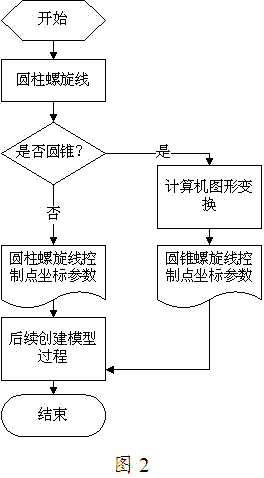

[0048] Embodiment 1: a method for building a composite fiber winding product model based on cylindrical helical curve and computer three-dimensional graphics transformation, comprising the following steps:

[0049] Step 1: Determine the diameter of the cylinder helix equation and the axial length of the helix according to the design requirements of the filament winding product, and then calculate the coordinate parameters of all coordinate control points on the center line of the filament winding model from the cylinder helix equation;

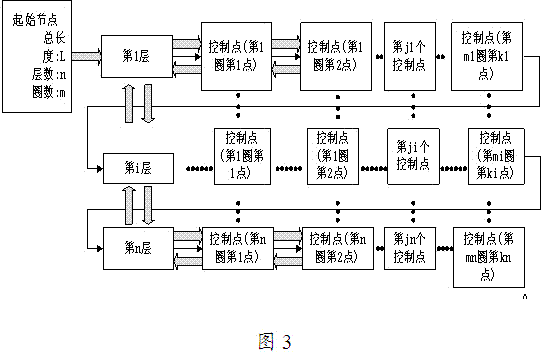

[0050] Step 2: Create a image 3 The mesh data set of the fiber centerline coordinate control points shown, wherein the coordinate parameters of all the centerline coordinate control points calculated by the cylindrical helix and the logical relationship between the coordinate control points are stored;

[0051] Step 3: For the adjustment of the coordinate control points of the jump / cross-circle part, several coordinate control points and the ...

Embodiment 2

[0053] Embodiment 2: a kind of method of constructing fiber winding model based on cylindrical helical curve and computer three-dimensional graphics transformation:

[0054] Step 1: Determine the spacing of the cylinder helix equation and the number of turns in the first layer according to the design requirements of the filament winding product, and then calculate the coordinate values of all coordinate control points of the center line of the filament winding model from the cylinder helix equation;

[0055] Step 2: Create a image 3 The mesh data set of the fiber centerline coordinate control points shown, wherein the coordinate parameters of all the centerline coordinate control points calculated by the cylindrical helix and the logical relationship between the coordinate control points are stored;

[0056] Step 3: For the adjustment of the coordinate control points of the jump / cross-circle part, several coordinate control points and the same number of coaxial reference pl...

Embodiment 3

[0058] Embodiment 3: a kind of method based on cylindrical helical curve and computer three-dimensional graphics transformation to construct filament winding model:

[0059] Step 1: Determine the diameter of the cylindrical helix equation, the axial length of the helix and the helix spacing according to the design requirements of the filament winding product, and then calculate the coordinate values of all coordinate control points of the centerline of the fiber winding model from the helix equation of the cylinder ;

[0060] Step 2: Create a image 3 The mesh data set of the fiber centerline coordinate control points shown, wherein the coordinate parameters of all the centerline coordinate control points calculated by the cylindrical helix and the logical relationship between the coordinate control points are stored;

[0061] Step 3: For the correction of the coordinate control points of the jump / cross-circle part, several coordinate control points and the same number of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com