Remote monitoring maintenance method for GYK equipment

A remote monitoring and equipment technology, applied in the field of electronic information, can solve the problems of not being able to grasp it in time, affecting the normal safety production of rail car users, and not being able to grasp the quality status of GYK equipment in real time, so as to achieve the effect of ensuring originality and real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing.

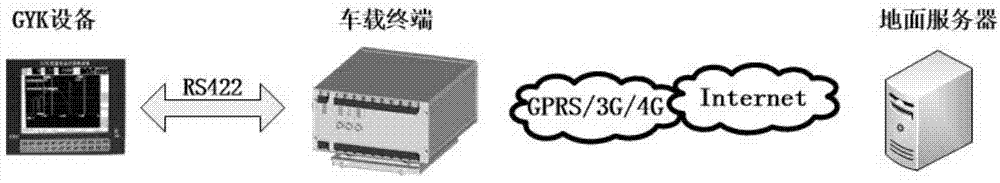

[0072] Such as figure 1 As shown, the GYK equipment remote monitoring and maintenance system realized by the present invention is composed of GYK equipment, a vehicle terminal, and a ground server. GYK is the monitored object; the vehicle-mounted terminal is the core part of the invention, responsible for data collection and synchronous transmission to the ground server; the ground server is responsible for receiving and analyzing remote monitoring data, and providing remote monitoring and maintenance services for users. The vehicle-mounted terminal establishes a communication connection with GYK equipment through RS422, and the vehicle-mounted terminal connects to the ground server through GPRS / 3G / 4G mobile network and Internet.

[0073] Such as figure 2 As shown, the GYK equipment remote monitoring and maintenance system workflow realized by the present invention is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com