DC long-term live-line test method and critical DC electric intensity determination method thereof

A technology of electric strength and long-term electrification, applied in the direction of testing dielectric strength, etc., can solve problems such as only electric life evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

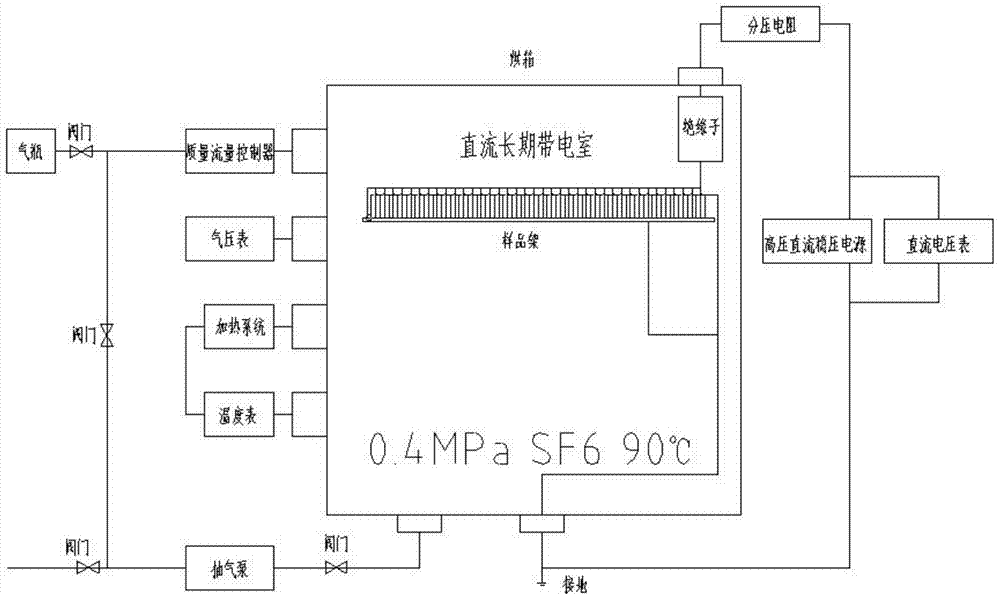

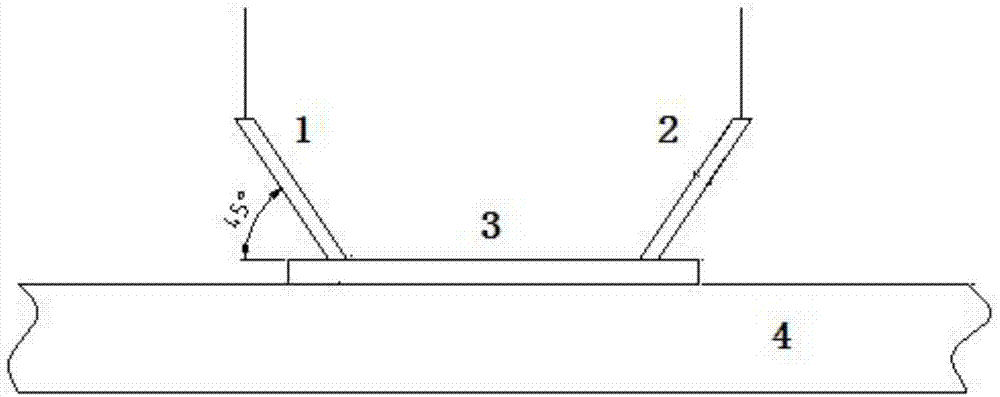

[0018] Such as figure 1 Shown is a typical long-term electrified test system, including gas systems (gas cylinders, valves, flow controllers, air pumps and barometers), the main functions of which are gas supply, gas pressure measurement, gas recovery and treatment (if the insulating medium is insulating oil etc., then directly rush into the charging room); the temperature control system (heating system and thermometer), the main function is to maintain the temperature of the charging room; the DC long-term charging room (sample rack, oven, sample, loading electrode, electrode wiring, etc.) The core device of the long-term live test; the voltage loading system (high-voltage DC regulated power supply, DC voltmeter, voltage dividing resistor, insulator, etc.), the main function is to provide stable DC high voltage.

[0019] The basic test process is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com