High-vacuum degree rotary sealing mechanism

A rotary sealing, high vacuum technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of vacuum damage, affecting the function of the mechanism, complex structure, etc., to achieve good fit and consistency, Stable deformation effect and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

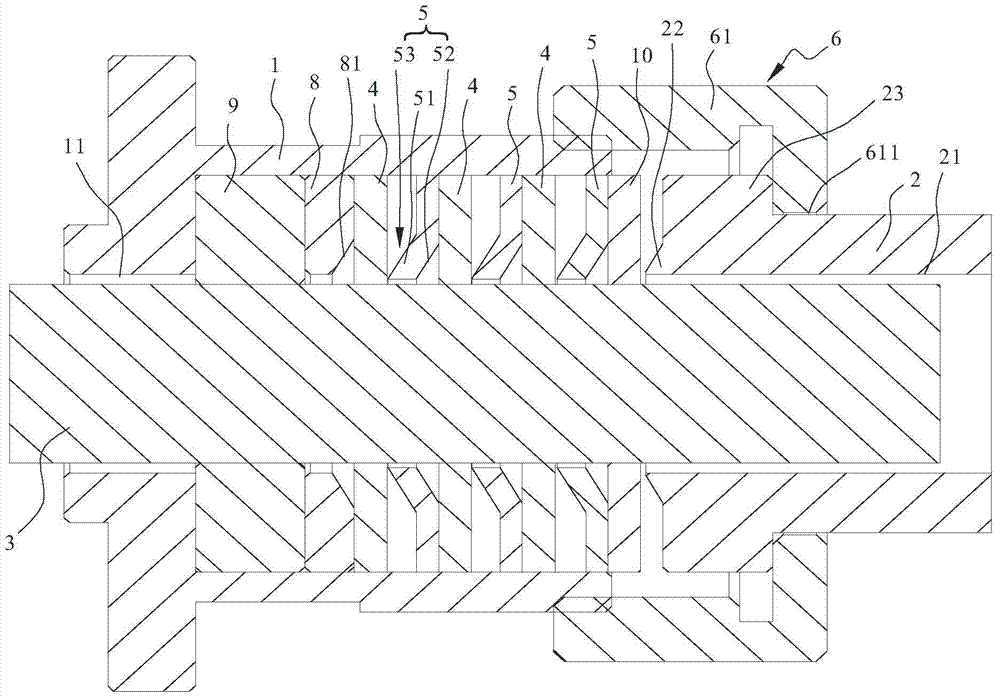

[0025] Such as Figure 1~2 The high vacuum rotary seal mechanism shown includes:

[0026] Sealing sleeve 1, the bottom of the sealing sleeve 1 is provided with a first perforation 11, the axial direction of the first perforation 11 is parallel to the axial direction of the sealing sleeve 1;

[0027] An indenter 2, the indenter 2 has a second perforation 21 through the indenter 2;

[0028] Rotating member 3, the rotating member 3 passes through and is pivotally mounted on the first through hole 11 and the second through hole 21, and a vacuum chamber 7 is formed between the second through hole 21 and the rotating member 3;

[0029] At least one first soft sealing ring 4, each first soft sealing ring 4 is hermetically fitted on the rotating member 3 and located in the sealing sleeve 1;

[0030] At least one hard pressure ring 5, each pressure ring 5 is sealed and sleeved on the rotating member 3, each pressure ring 5 is correspondingly equipped with a first soft seal ring 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com