Building formwork pull rod

A technology of building templates and tie rods, which is applied in construction, building construction, and on-site preparation of building components. It can solve problems such as unevenness, cumbersome casing work, and poor contact surfaces, and achieve good sealing effect and simplify Effect of installation process and contact surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

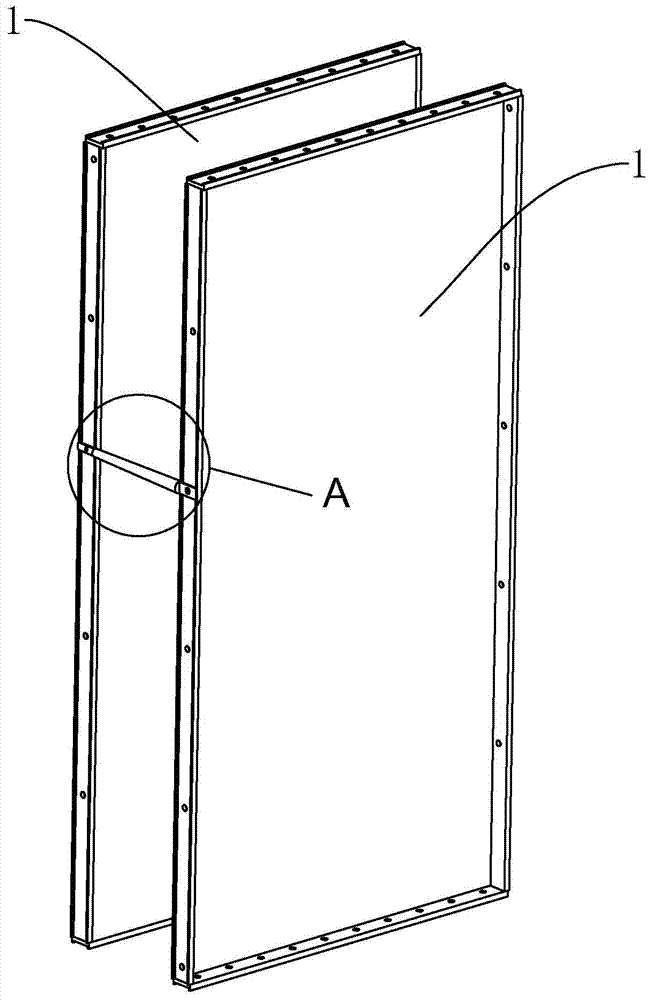

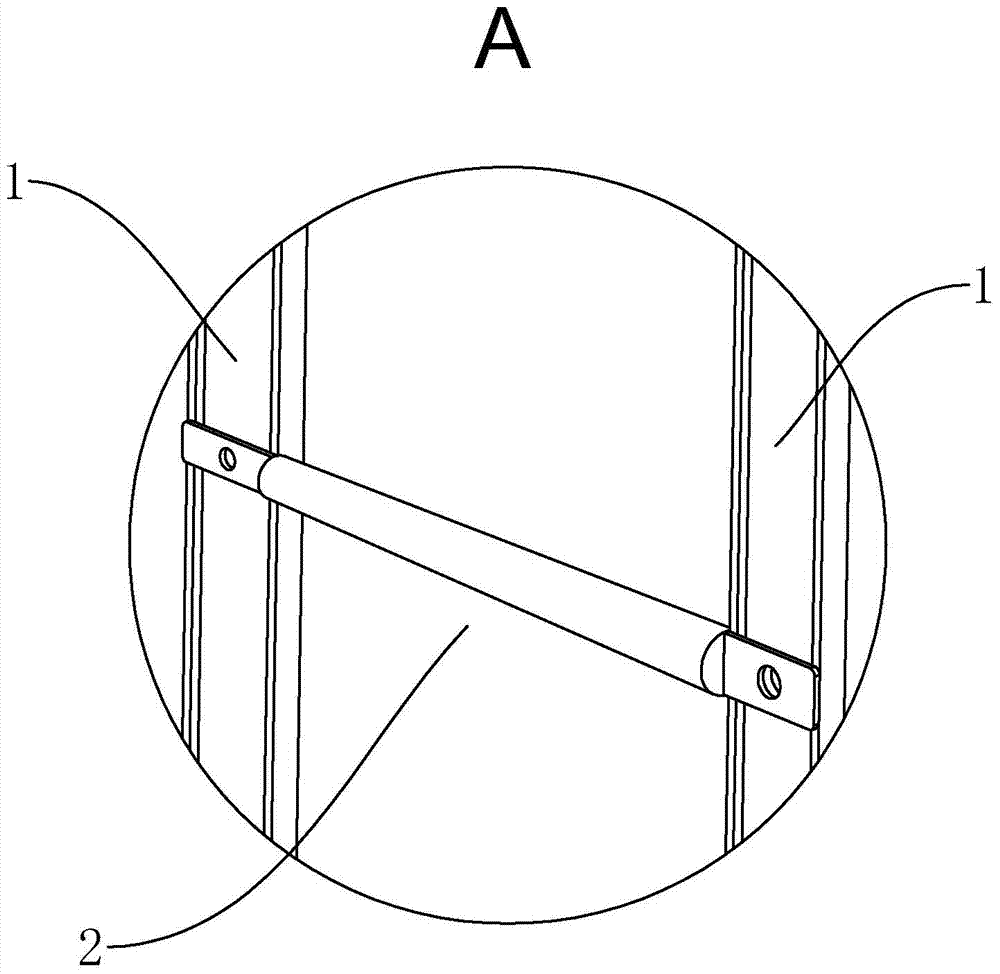

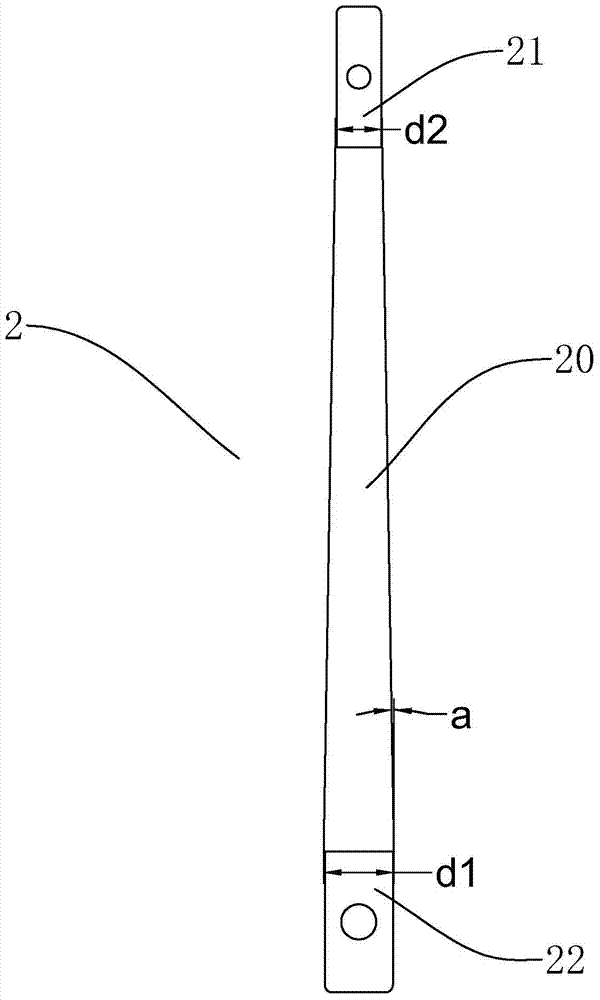

[0015] refer to Figure 1 to Figure 3 , figure 1 , figure 2 It is a schematic diagram of the application of a specific embodiment of the present invention, image 3 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, the building formwork tie rod includes a tie rod body 1 arranged between two building formworks. Connecting parts 21, 22, the cross-section of the rod body 20 is circular, and the diameters d1 and d2 of the cross-sections at both ends of the rod body 20 are not equal, so that the rod body 20 forms a cone with a certain slope angle similar to the draft design in the mold shaped structure, when the concrete is cured, tap the rod body 20 from the end with a smaller diameter to the end with a larger diameter to take out the main body 1 of the tie rod, which is very convenient to take out, and there is no need to cover plastic pipes, saving a lot of plastic pipes and The installation process of the pull ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com