All-directional constant-temperature wine cellar with sub-control adjustment function

An all-round, wine cellar technology, applied in wine cellar utensils, biochemical equipment and methods, etc., can solve problems such as high cost, cumbersome manufacturing process and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Now the present invention is further described in conjunction with description of drawings and embodiments:

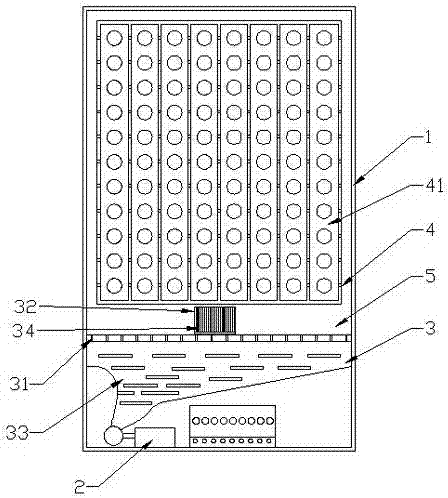

[0016] refer to figure 1 , an all-round constant temperature wine cellar with sub-control adjustment, including a wine cellar main body 1 and a temperature and humidity control device 2 in the wine cellar main body 1, a diffuser device 3 and a wine rack 4, wherein: the wine rack 4 is located in the wine cellar The wine storage space 5 above the interior of the cellar main body 1, the wine storage space 5 is a square space with a size of 110cm X 45cm X 135cm, the wine storage space 5 is between the wine rack 4 and the inner wall of the wine cellar body There is an air circulation space with a distance of 10cm between them. The inside of the wine rack 4 is provided with seven partitions, which divide the inside of the wine rack 4 into eight vertical wine storage channels 41. The two sides of the wine storage channels 41 are arranged according to the The size of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com