Method for controlling automatic liquor blending by virtue of real-time smell detection technology

A technology of odor detection and real-time detection, applied in the field of liquor automatic blending control algorithm, which can solve the problems of taste deviation and ratio error of blended products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

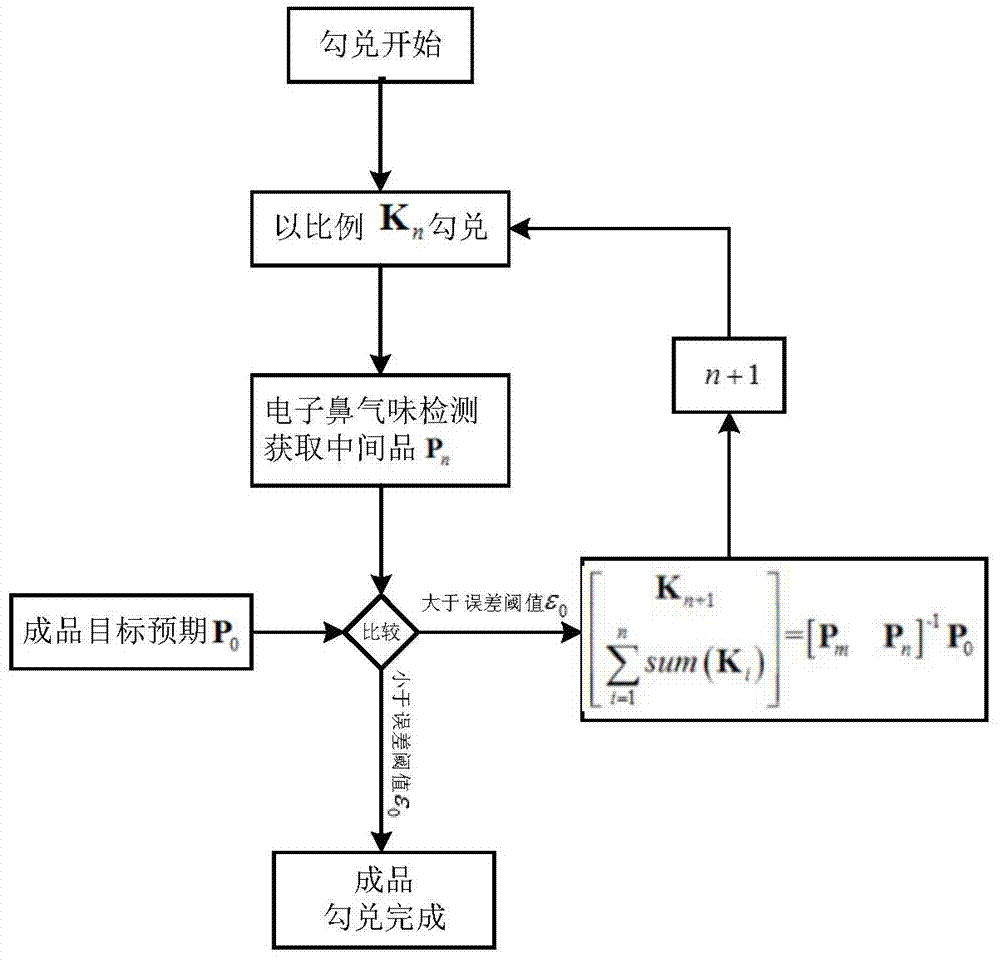

[0023] Below in conjunction with accompanying drawing and concrete example step further explanation:

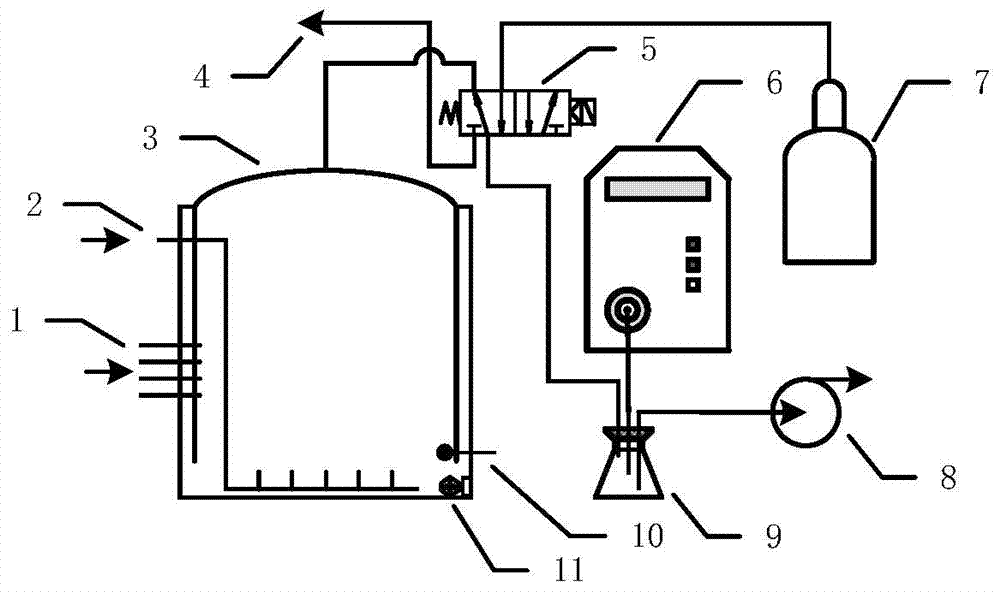

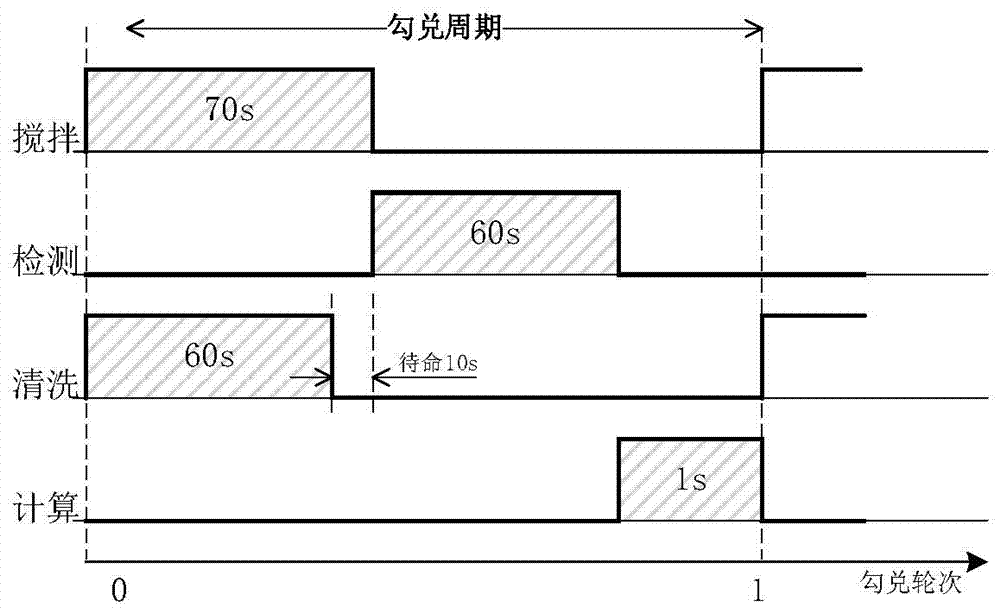

[0024] Real-time detection during the blending process figure 2 completed in the real-time odor detection system, and in accordance with image 3 The timing proceeds:

[0025] a) The base wine enters the blending tank 3 through the input pipe 1, and is stirred by inputting clean compressed air 2, and the process takes 70 seconds;

[0026] b) At the same time, control the reversing solenoid valve 5 in the 1 state, connect the clean nitrogen gas 7 and the gas sampling bottle 9, and use the clean nitrogen gas 7 to clean the electronic nose 6, which takes 60 seconds, and then the electronic nose 6 enters the standby state;

[0027] c) After cleaning, control the reversing solenoid valve 5 in the 2 state, connect the blending tank 3 and the gas sampling bottle 9, and turn on the air pump 8 to suck the liquor volatile gas into the gas sampling bottle 9, which takes 10 seconds; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com