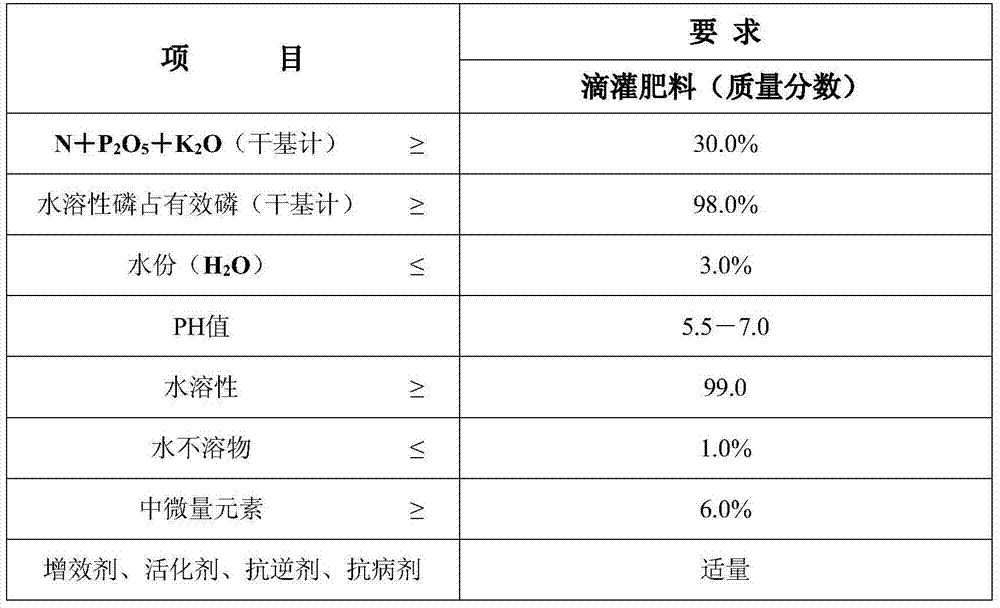

Multifunctional drip-irrigation fertilizer and preparation method thereof

A multi-functional, drip irrigation fertilizer technology, applied in the direction of inorganic fertilizers, nitrate fertilizers, fertilizer mixtures, etc., can solve the problems of high cost of comprehensive soil disinfection, difficulty in eradicating germs, and large soil area of disease, so as to improve crop yield and Quality, improvement of crop stress resistance, and the effect of rich nutrient elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) The raw materials potassium nitrate, potassium sulfate, monoammonium phosphate, urea, magnesium sulfate, and calcium nitrate are respectively pulverized with a ring hammer mill, and the fineness reaches 28-42 mesh, and then the above-mentioned components are mixed in a certain proportion Add it into a horizontal gravity-free mixer and mix for 5-7 minutes. The ratio of each component is: potassium nitrate 240kg, potassium sulfate 250kg, monoammonium phosphate 102kg, urea 205kg, magnesium sulfate 76kg, calcium nitrate 90kg;

[0039] (2) Put 5kg of zinc sulfate, 10kg of manganese sulfate, 7kg of boric acid, 1kg of sodium selenite, 4kg of polyaspartic acid, 8kg of amino oligosaccharin, and 2kg of 70% stimulating antibiotics (968 antibiotics) into the "V"-shaped mixer Mix in medium for 14 minutes;

[0040] (3) pulverizing the mixed material obtained in step (2) through an ultrafine pulverizer so that its fineness reaches 120-150 mesh;

[0041] (4) Add the mixed fine mat...

Embodiment 2

[0043] (1) The raw materials potassium nitrate, potassium sulfate, monoammonium phosphate, urea, magnesium sulfate, and calcium nitrate are respectively pulverized with a ring hammer mill, and the fineness reaches 28-42 mesh, and then the above-mentioned components are mixed in a certain proportion Add it into a horizontal gravity-free mixer and mix for 5-7 minutes. The ratio of each component is: potassium nitrate 232kg, potassium sulfate 260kg, monoammonium phosphate 130kg, urea 170kg, magnesium sulfate 80kg, calcium nitrate 90kg;

[0044] (2) Put 5kg of zinc sulfate, 10kg of manganese sulfate, 7kg of boric acid, 1kg of sodium selenite, 4kg of polyaspartic acid, 8kg of amino oligosaccharin, and 2kg of 70% stimulating antibiotics (968 antibiotics) into the "V"-shaped mixer Mix in medium for 13 minutes;

[0045] (3) pulverizing the mixed material obtained in step (2) through an ultrafine pulverizer so that its fineness reaches 120-150 mesh;

[0046] (4) Add the mixed fine mat...

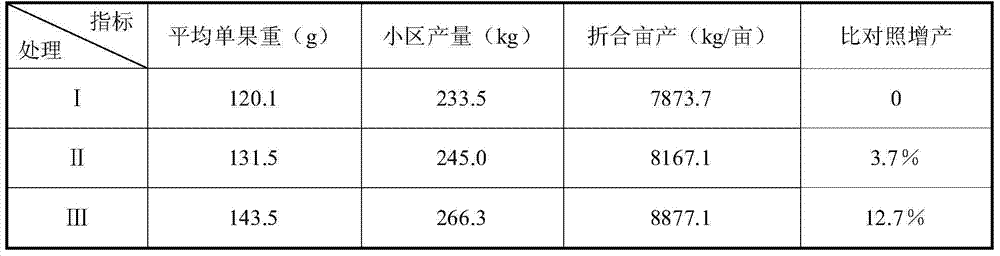

Embodiment 3

[0048](1) The raw materials potassium nitrate, potassium sulfate, monoammonium phosphate, urea, magnesium sulfate, and calcium nitrate are respectively pulverized with a ring hammer mill, and the fineness reaches 28-42 mesh, and then the above-mentioned components are mixed in a certain proportion Add it into a horizontal gravity-free mixer and mix for 5-7 minutes. The ratio of each component is: potassium nitrate 207kg, potassium sulfate 278kg, monoammonium phosphate 141kg, urea 160kg, magnesium sulfate 95kg, calcium nitrate 86kg;

[0049] (2) Put 7kg of zinc sulfate, 6kg of manganese sulfate, 6kg of boric acid, 2kg of sodium selenite, 5kg of polyaspartic acid, 6kg of amino oligosaccharin, and 1.5kg of 70% stimulating antibiotics (968 antibiotics) into a "V" shape and mix Mix in the machine for 12 minutes;

[0050] (3) pulverizing the mixed material obtained in step (2) through an ultrafine pulverizer so that its fineness reaches 120-150 mesh;

[0051] (4) Add the mixed fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com