Structure capable of mounting and dismounting balancing weight automatically by tower crane

A counterweight and self-installation technology, which is applied in cranes, transportation and packaging, etc., can solve problems such as difficult to complete the hoisting of the counterweight, inconvenient operation of the vehicle crane, and the limit of the vehicle's hoisting, so as to solve the problem of difficult installation or disassembly of the counterweight, structural problems, etc. Simplicity and effect of equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

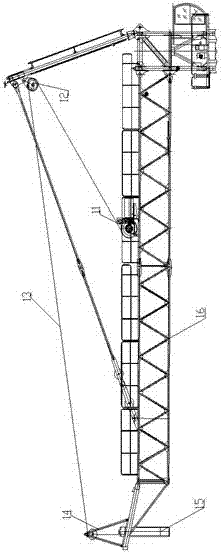

[0017] Such as figure 1 As shown, the present invention includes a hoisting mechanism 11 installed on the balance arm 16, a hoisting pulley 12 installed on the top of the tower, a self-hanging counterweight device 14 installed at the outer end of the balance arm 16, and a self-hanging counterweight device 1 mounted on the balance arm 16. Balance weight 15 and steel wire rope 13 below.

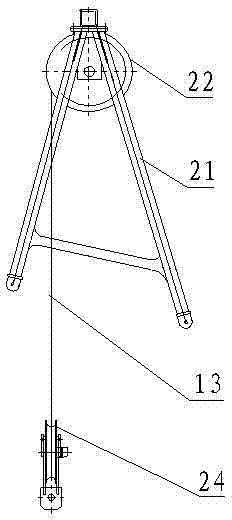

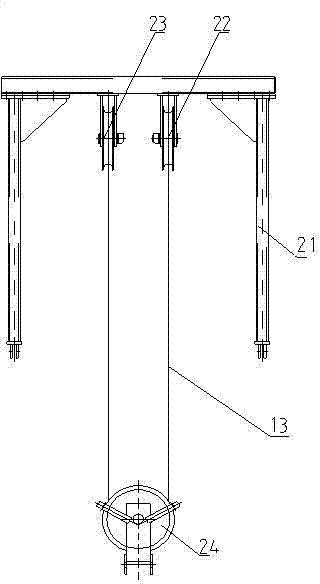

[0018] Such as figure 2 and image 3 As shown, the self-hanging counterweight device 14 is fixed on the balance arm 16 through a bracket 21 . It includes a bracket 21 fixedly connected with the self-hanging counterweight device 14, a first upper pulley 22 and a second upper pulley 23 installed on the bracket 21, and a lower pulley 24 located below the two, and the lower pulley 24 is hoisted by a pin shaft Balance weight 15.

[0019] Such as figure 1 and image 3 As shown, the wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com