Horizontal finishing batching machine

A cloth rolling machine and horizontal technology, which is applied in the field of horizontal finishing cloth rolling machine, can solve the problems of changing the line speed and affecting the processing effect of the cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

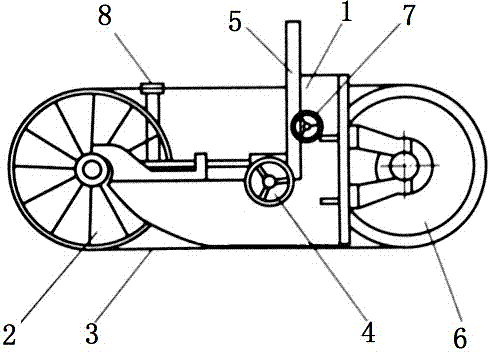

[0011] Such as figure 1 As shown, the horizontal finishing and winding machine of the present invention includes a support 1, on which two rollers are arranged, and the rollers are tensioned and connected by a belt 3, and a roller is connected with a coaxial key on the rollers. An adjustment device is provided on the support 1, and the adjustment device includes a horizontal distance adjustment device and a vertical distance adjustment device. A horizontal runner 4 is arranged on the top, and the coaxial key on the horizontal runner 4 is connected with a gear meshed with a horizontal rack. The vertical adjustment device includes a vertical fixed rack 5, a vertical tooth is provided on the vertical bracket of the right roller 6, the vertical tooth is meshed with the fixed rack, and the vertical tooth is connected with a vertical wheel by a coaxial key. 7. The diameters of the two rollers 2 on the support 1 are the same. The diameter of horizontal runner 4 is greater than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com