Device for crushing PCB photosensitive film plate-type raw material

A raw material crushing and photosensitive film technology, which is applied in grain processing and other directions, can solve the problems of undurable cutting tools and low crushing efficiency, and achieve the effect of low equipment manufacturing cost and improved crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

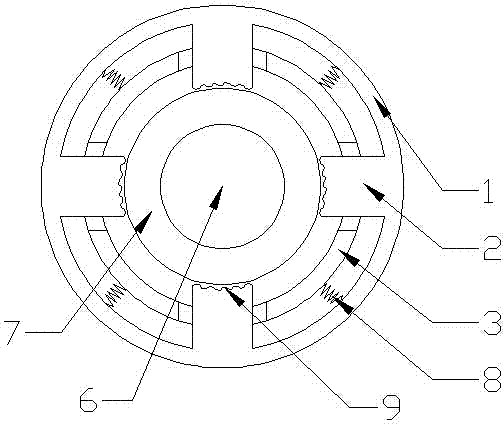

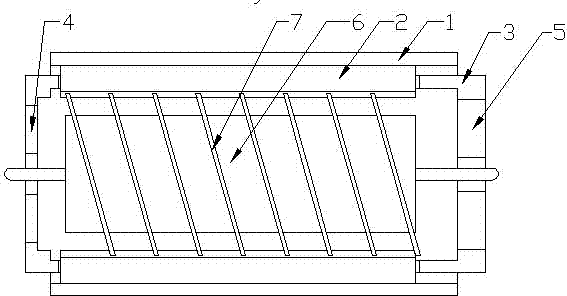

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0022] Such as Figure 1~2 As shown, a photosensitive film plate type raw material crushing device for PCB includes a crushing bucket 3 and a crushing assembly;

[0023] The crushing assembly includes a blade assembly and a vibrator block 2 assembly, the two ends of the crushing barrel 3 are sealed, a feed port 4 is arranged at the sealed end of the crushing barrel 3, and a discharge port 5 is arranged at the sealed end of the crushing barrel 3 , the blade assembly includes a main shaft 6 and a helical blade 7 arranged on the main shaft 6, the helical axis of the helical blade 7 is coaxial with the axis of the main shaft 6;

[0024] The vibrator block 2 asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com