A kind of kiln tail gas purification device and purification method

The technology of a tail gas purification device and a kiln, which is applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problems such as immature tail gas treatment methods, difficult tar removal work, influence of oxygen content in the furnace, etc. Achieve the effect of avoiding repetitive work, facilitating pressure regulation, and achieving centralized recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

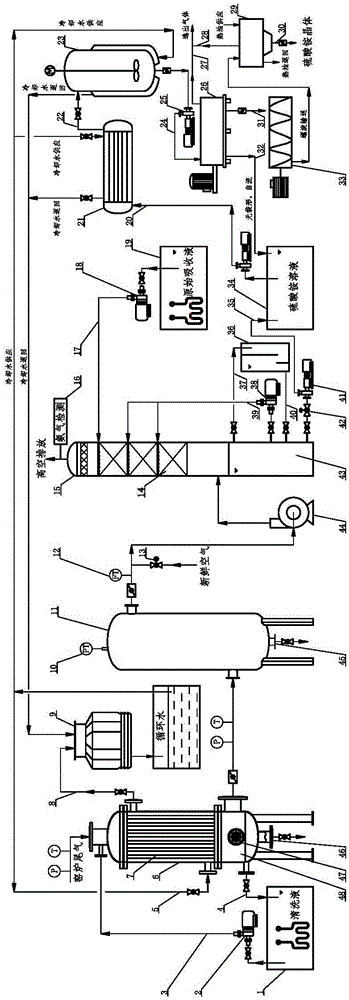

[0038] The present invention will be further described below in conjunction with accompanying drawing:

[0039] Such as figure 1A kiln tail gas purification device shown includes a cleaning tank 1, a tar condenser 6, a cooling tower 9, a pressure buffer tank 11, a frequency conversion fan 44, a spray absorption tower 15, an original absorption liquid pool 19, and an ammonium sulfate transfer pool 34. Cooler 21, crystallization tank 23, centrifuge 26, mixer 33, dryer 29.

[0040] Specifically, in the tar condenser 6, its cooling water inlet and outlet are respectively connected to the cooling tower 9 through the cooling water supply pipeline 5 and the cooling water return pipeline 8; its cleaning liquid inlet and outlet are respectively passed through the cleaning pump 2 and the cleaning liquid supply pipeline 3, the cleaning liquid return pipeline 4 are connected to the cleaning tank 1; the gas outlet thereof is connected to the air inlet of the buffer tank 11.

[0041] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com