Soft material sticking structure device

A technology of soft materials and laminating sheets, which is applied in the direction of bonding shoe parts, clothing, shoemaking machinery, etc., and can solve the problems of easily damaged surfaces and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

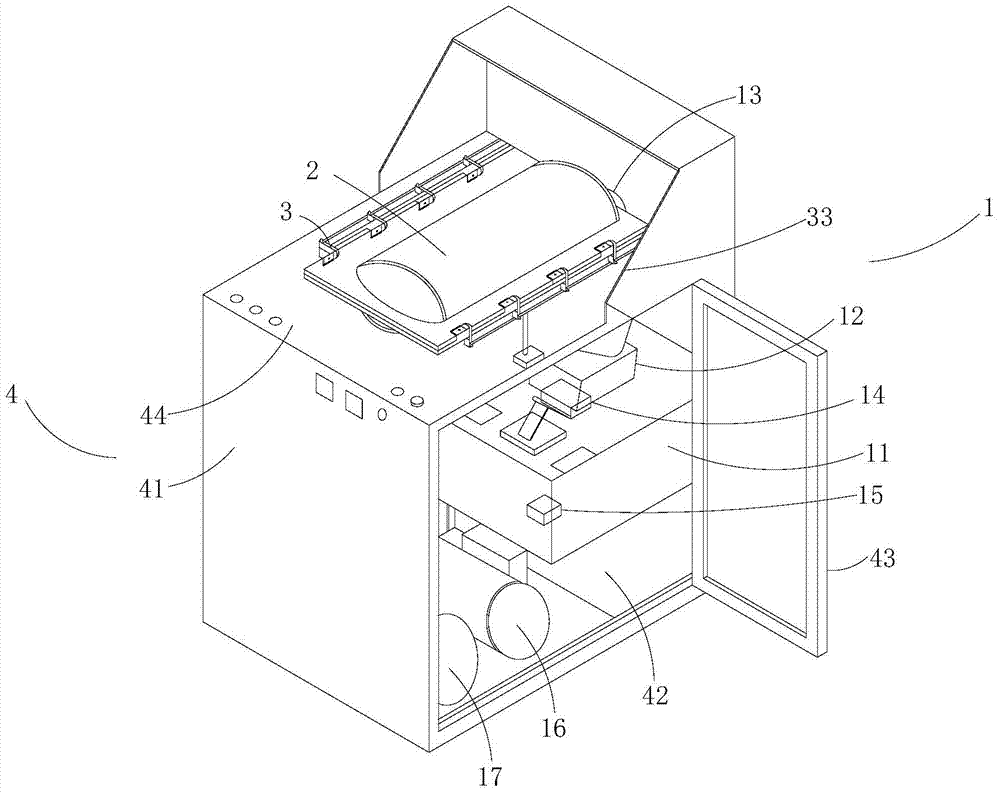

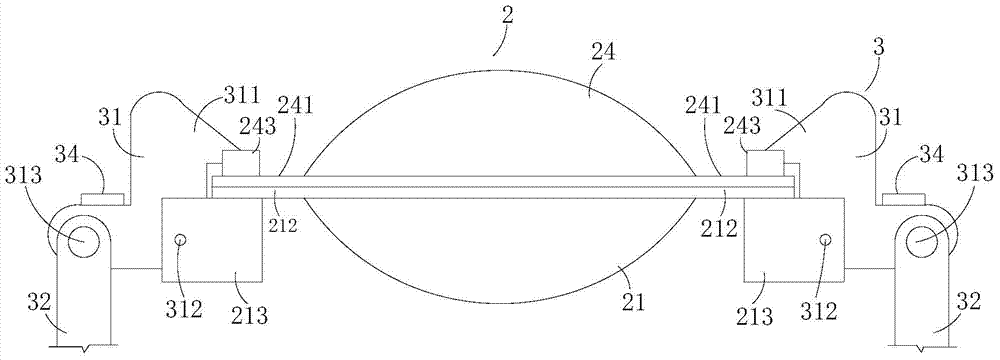

[0022] The present invention relates to a soft material bonding structure device, (please refer to figure 1 ) which includes:

[0023] A power group 1 is mainly composed of an air compressor 11, an upper cover cylinder 12, an opening and closing arm 13, a pressure regulator 14, a timer 15, a vacuum pump 16 and a vacuum box 17, and an upper cover cylinder is arranged above the air compressor 11 12. The upper cover cylinder 12 is upwardly connected with an opening and closing arm 13, the opening and closing arm 13 can open or close the fitting group 2, and the upper cover cylinder 12 is connected with a pressure regulator 14, and the side of the air compressor 11 is respectively set There is a timer 15, a vacuum pump 16 and a vacuum box 17. The vacuum pump 16 and the vacuum box 17 can vacuumize the inner cabin 28, the upper outer cabin 26 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com