A thresher with anti-clogging function

An anti-clogging and thresher technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as time-consuming and labor-intensive, safety hazards, etc., to eliminate safety hazards, effectively eliminate blockages, improve work efficiency and operation reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

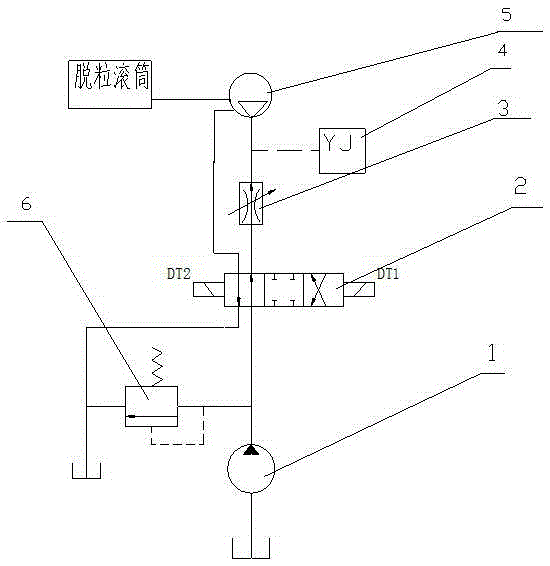

[0016] figure 1 Shown is the hydraulic transmission system diagram of the threshing machine of this embodiment. The main shaft of the drum of the threshing machine is connected with the main shaft of the hydraulic motor 5 through a coupling. By adjusting the opening of the speed regulating valve 3, different pressure oil flows entering the hydraulic motor 5 can be obtained, so that the hydraulic motor can obtain different speeds, thereby realizing stepless speed regulation of the threshing drum.

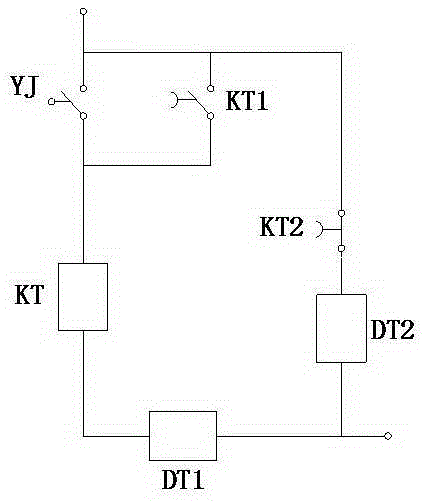

[0017] When the threshing machine is blocked, the pressure of the hydraulic system increases, and when the pressure reaches the set pressure of the pressure relay (YJ) 4, the YJ circuit is connected (see figure 2 ), the three-position four-way valve electromagnetic reversing valve 2 switches the oil circuit, the hydraulic motor 5 and the threshing drum reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com