Refrigerator

A technology of refrigerators and refrigeration devices, applied in the field of refrigerators, which can solve problems such as rising, difficulty following temperature changes, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

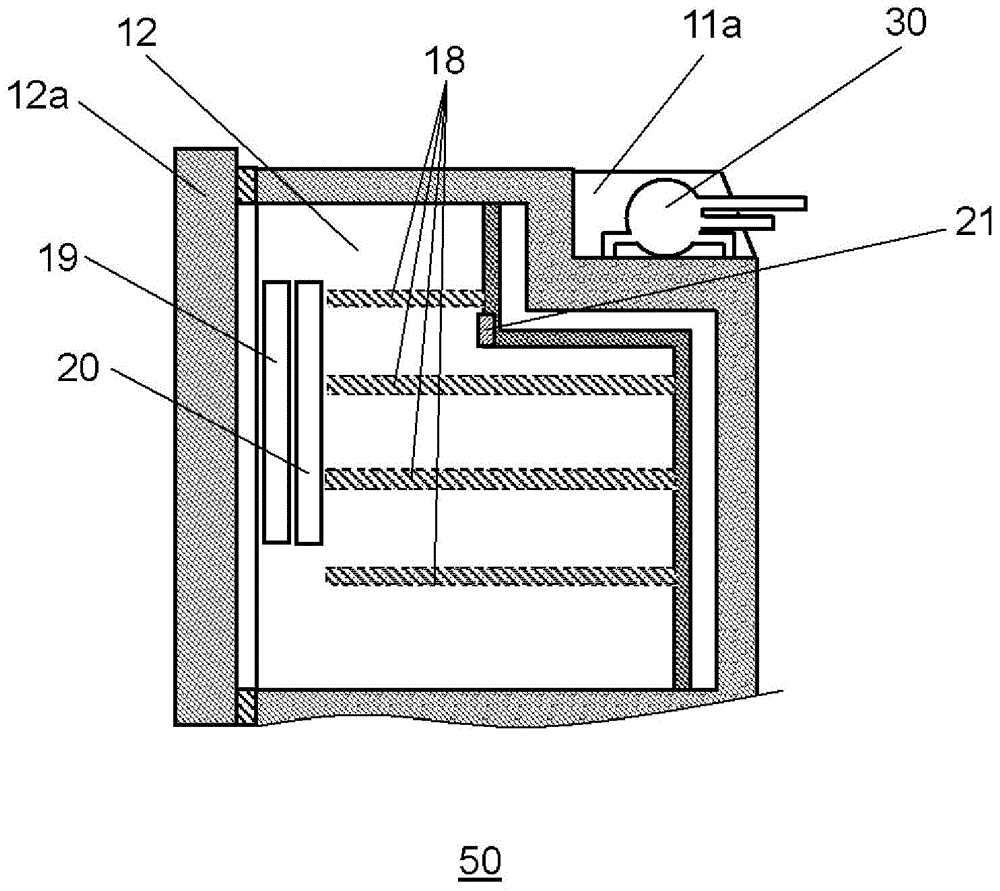

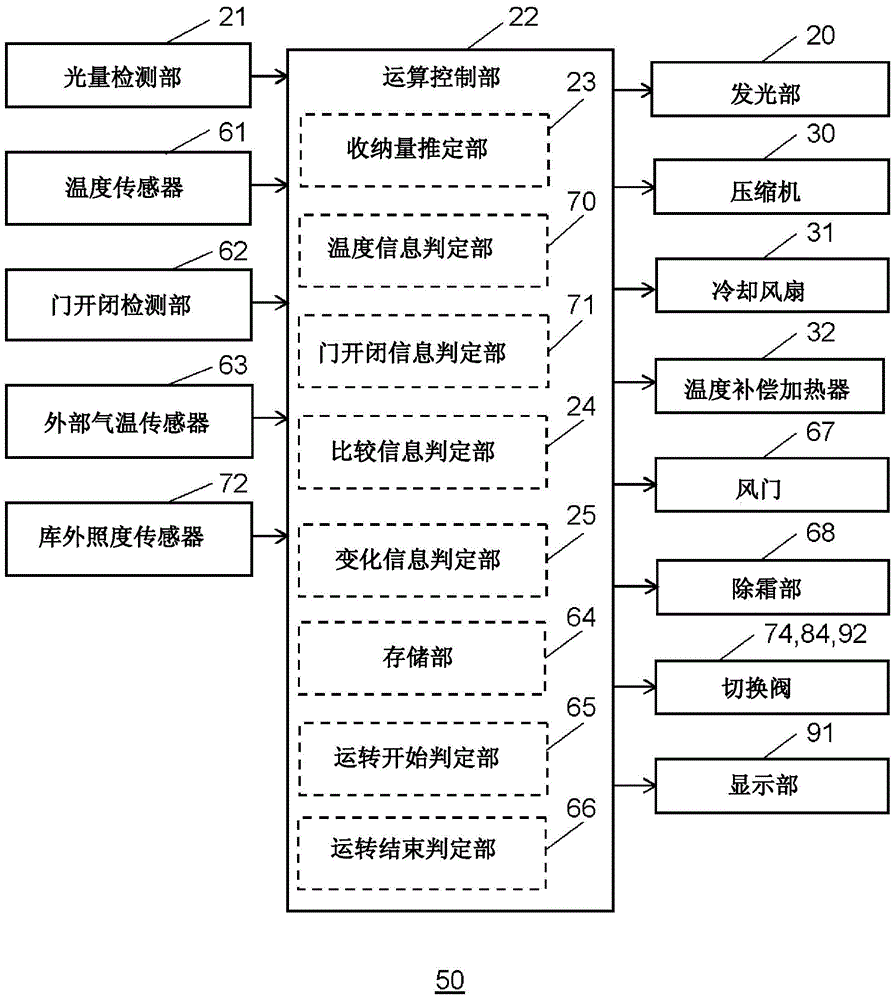

[0061] figure 1 It is a front view of refrigerator 50 in 1st Embodiment of this invention.

[0062] Such as figure 1 As shown, refrigerator 50 includes refrigerator main body 11 . The main body 11 of the refrigerator is a heat-insulating box, which mainly has an outer box made of steel plate, an inner box formed of resin such as ABS, and a heat-insulating material such as polyurethane provided in the space between the outer box and the inner box. insulation.

[0063] Refrigerator main body 11 is thermally insulated and divided into a plurality of storage rooms. Refrigerating room 12 is provided at the uppermost part, and ice making room 13 and switching room 14 are arranged side by side at the lower part of refrigerating room 12 . Freezer compartment 15 is disposed below ice making compartment 13 and switching compartment 14 , and vegetable compartment 16 is disposed at the lowest portion.

[0064] In the front of each storage compartment, a door is provided in the fron...

no. 2 Embodiment approach

[0203] Figure 17 It is a figure which schematically shows the refrigerant circuit of the refrigerator which concerns on 2nd Embodiment of this invention. Among them, the same configuration and the same technical idea as those described in detail in the first embodiment of the present invention can be applied in combination with this embodiment without inappropriate parts, and detailed descriptions are omitted.

[0204] Figure 17 In this case, the high-temperature, high-pressure refrigerant compressed by the compressor 30 is condensed in the condenser 81 and switched by the switching valve 74 downstream of the condenser 81 . And one side of the switching valve 74 communicates with the heat dissipation pipe 75 for preventing dew condensation arranged on the periphery of the front opening of the refrigerator, and then is decompressed by the capillary tube 83 , evaporates in the cooler 85 , and returns to the compressor 30 . In addition, the other side of the switching valve 7...

no. 3 Embodiment approach

[0231] Figure 18 It schematically shows the refrigerant circuit of the refrigerator which concerns on 3rd Embodiment of this invention. Among them, the same configuration and the same technical idea as those described in detail in Embodiments 1 and 2 can be used in combination with the present embodiment without inappropriate parts, and detailed descriptions are omitted.

[0232] Figure 18 In this case, the high-temperature, high-pressure refrigerant compressed by the compressor 30 is condensed in the condenser 81 and switched by the switching valve 92 downstream of the condenser 81 . One side of switching valve 92 is connected to cooler 94 for freezer compartment via capillary tube 93a, and the other side of switching valve 92 is connected to cooler 95 for refrigerator compartment via capillary tube 93b.

[0233] That is, it is characterized in that by providing the cooler 94 for the freezer compartment and the cooler 95 for the refrigerator compartment, switching the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com