Support steel pipe for scaffolding or timbering

A formwork support and scaffolding technology, which is applied in the connection of scaffolding, accessories of scaffolding, pillars, etc., can solve the problems of high risk and danger, and achieve the effect of excellent safety, excellent strength, and reduction of scaffolding parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

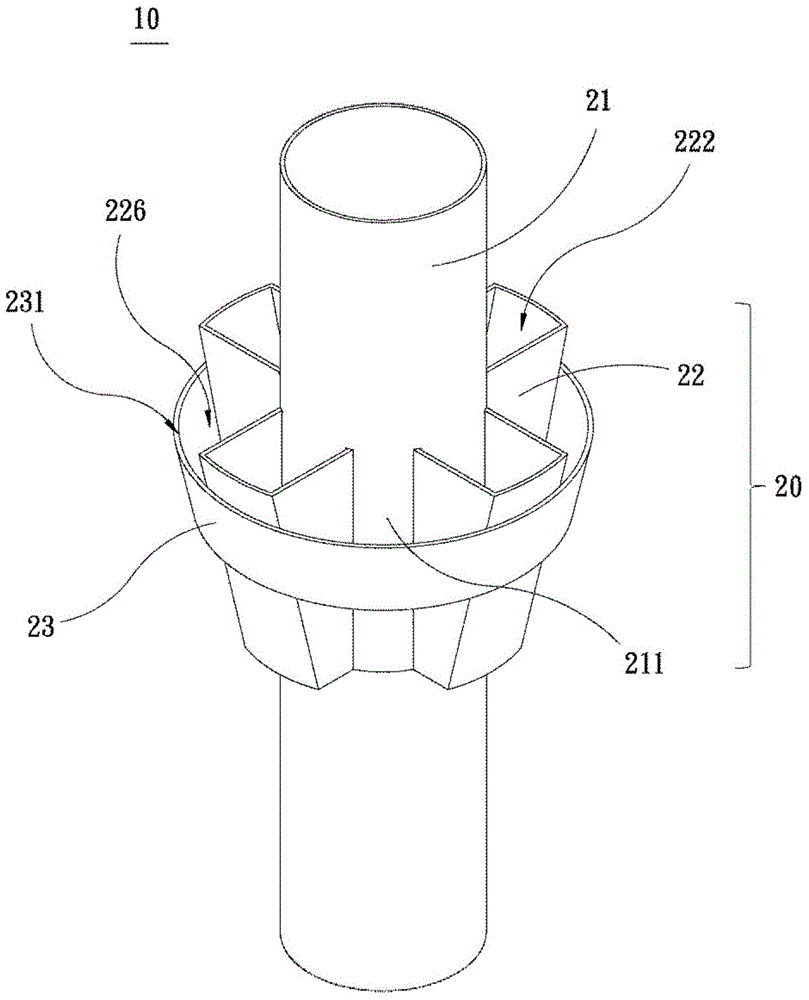

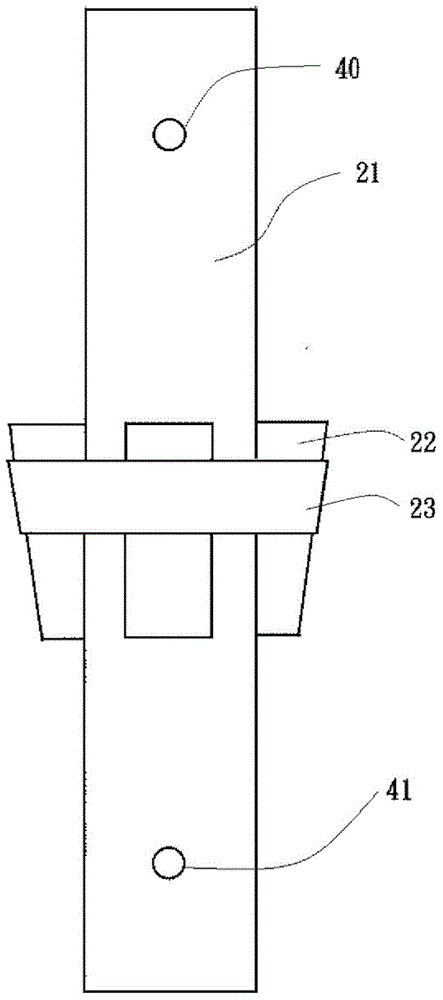

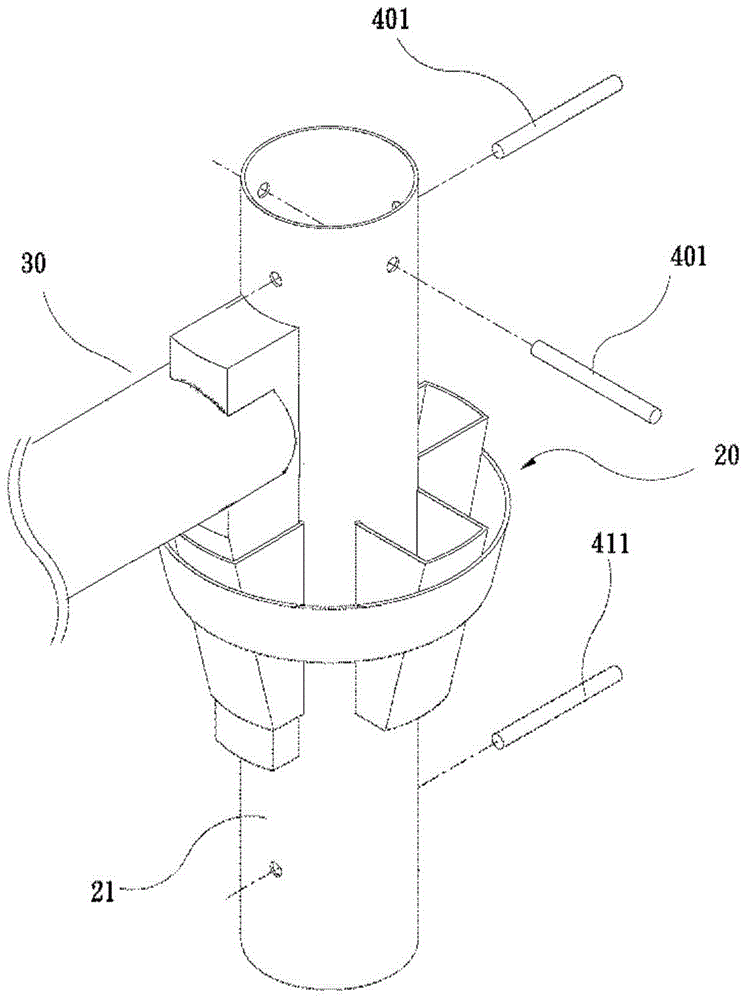

[0067] The steel pipe for pillars of the present invention is assembled and used as a scaffold, a formwork support, or a formwork support and a scaffold. The steel pipes for a plurality of pillars are erected at predetermined intervals in places where scaffolding or formwork supports are required by erecting desired horizontal bars. Moreover, by connecting the steel pipes for pillars to each other in the axial direction of the steel pipes for pillars, it is possible to form a scaffold or a formwork support to a desired height. By inserting the wedge-shaped portion provided at the end of the cross-bar into the wedge-shaped hole of the support member of the cross-bar connecting portion provided on the side surface of the steel pipe for the pillar, the cross-bar and the steel pipe for the pillar are combined and assembled into a predetermined structure.

[0068] The steel pipe 10 for struts of the present invention is provided with at least one cross-bar connecting portion 20 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com