Model and method of provincial electric power metering center production plan prediction software system

A technology of production planning and power measurement, which is applied in the direction of program control devices, etc., can solve problems such as the lack of design of mathematical models and scientific algorithm management, the difficulty of manual planning, and the complexity of production scheduling, so as to reduce the dependence on work experience and improve Program availability, effects of supporting algorithm capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

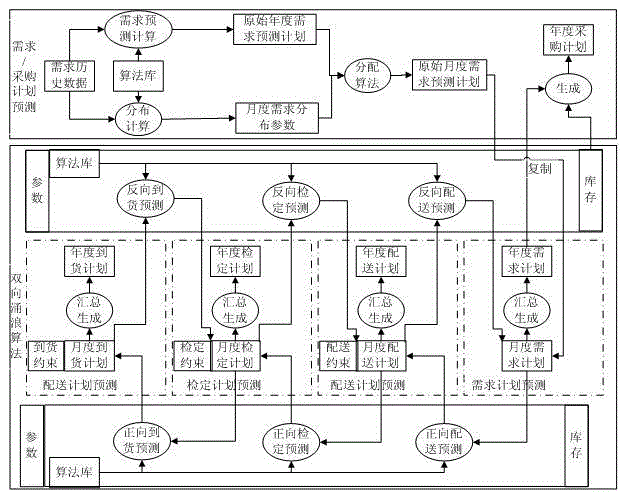

[0237] The following is a typical embodiment of the present invention, which includes a specific process of realizing the plan prediction by the method of the present invention through two-way surges. This embodiment has been obtained in the software prototype system based on the model and algorithm development of the present invention verify. Other characteristics, objects and advantages of the present invention can also be seen from the description of the embodiments.

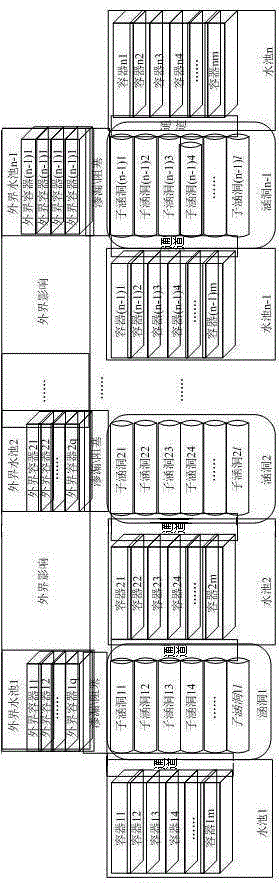

[0238] Predicting various production plans for the next year needs to go through two main stages. The first stage is the annual demand plan for the next year, the monthly demand plan forecast for the next year, and the annual procurement plan forecast, which is equivalent to the basic data forecast stage of the forecast. The second stage is to use the core algorithm of the present invention (two-way surge algorithm) to predict the monthly and annual plans of delivery, verification, and arrival, and may change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com