Shaped-steel concrete frame-steel supporting structure type steel column preconstraint node

A steel support and concrete technology, applied in building structure, construction and other directions, can solve the problems of tension between steel bars and steel bars, difficult anchoring of steel bars, dense steel bars, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

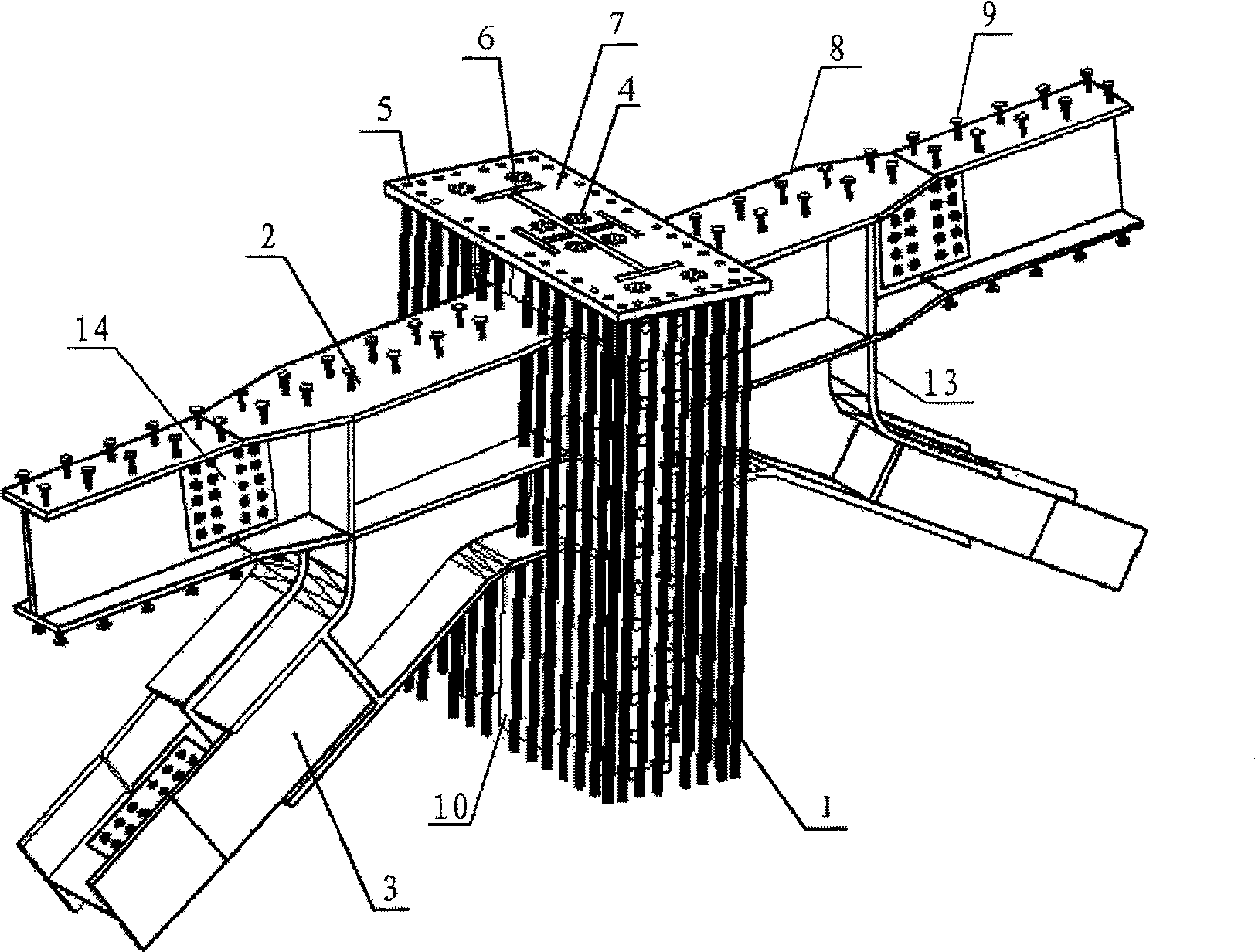

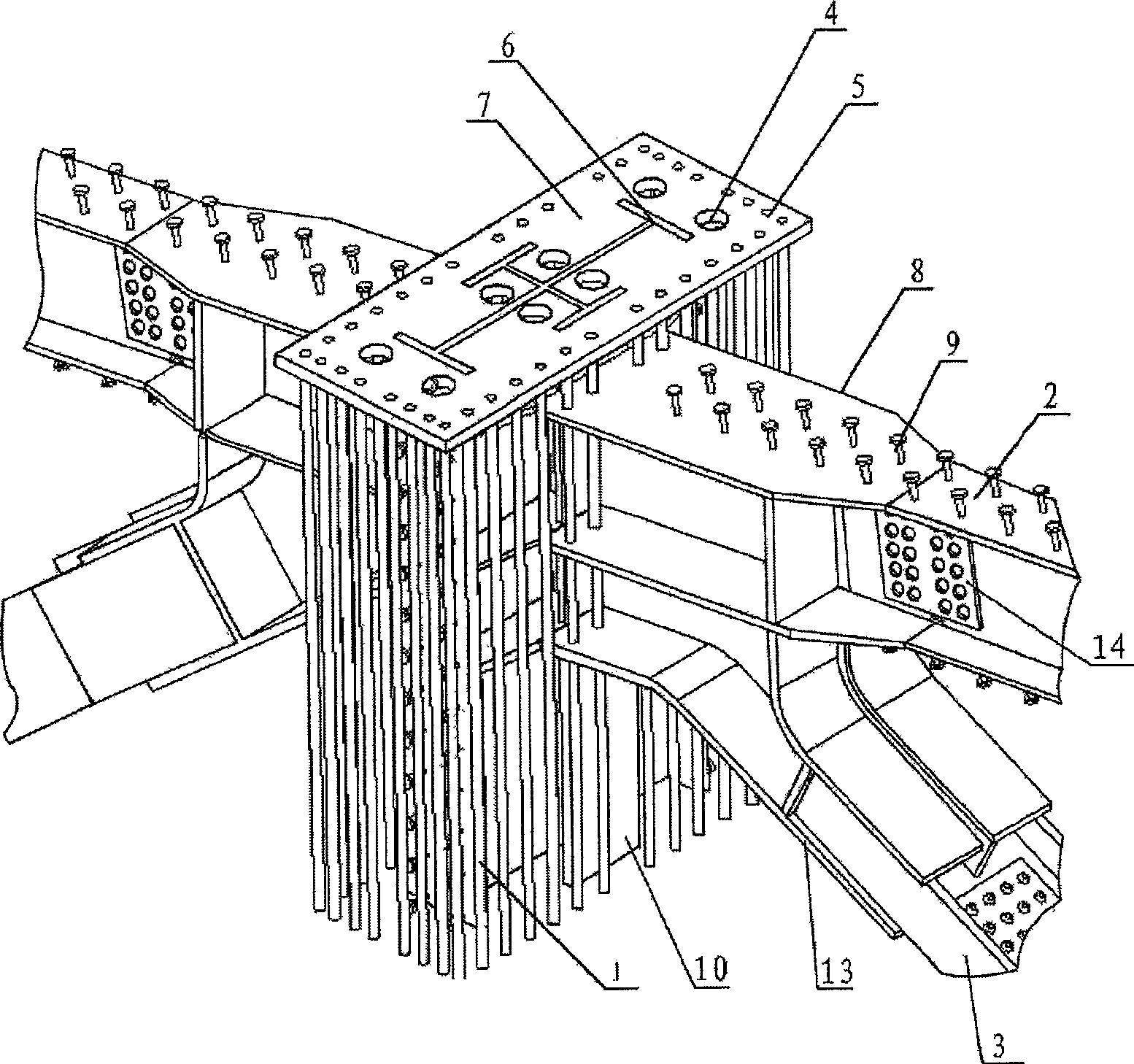

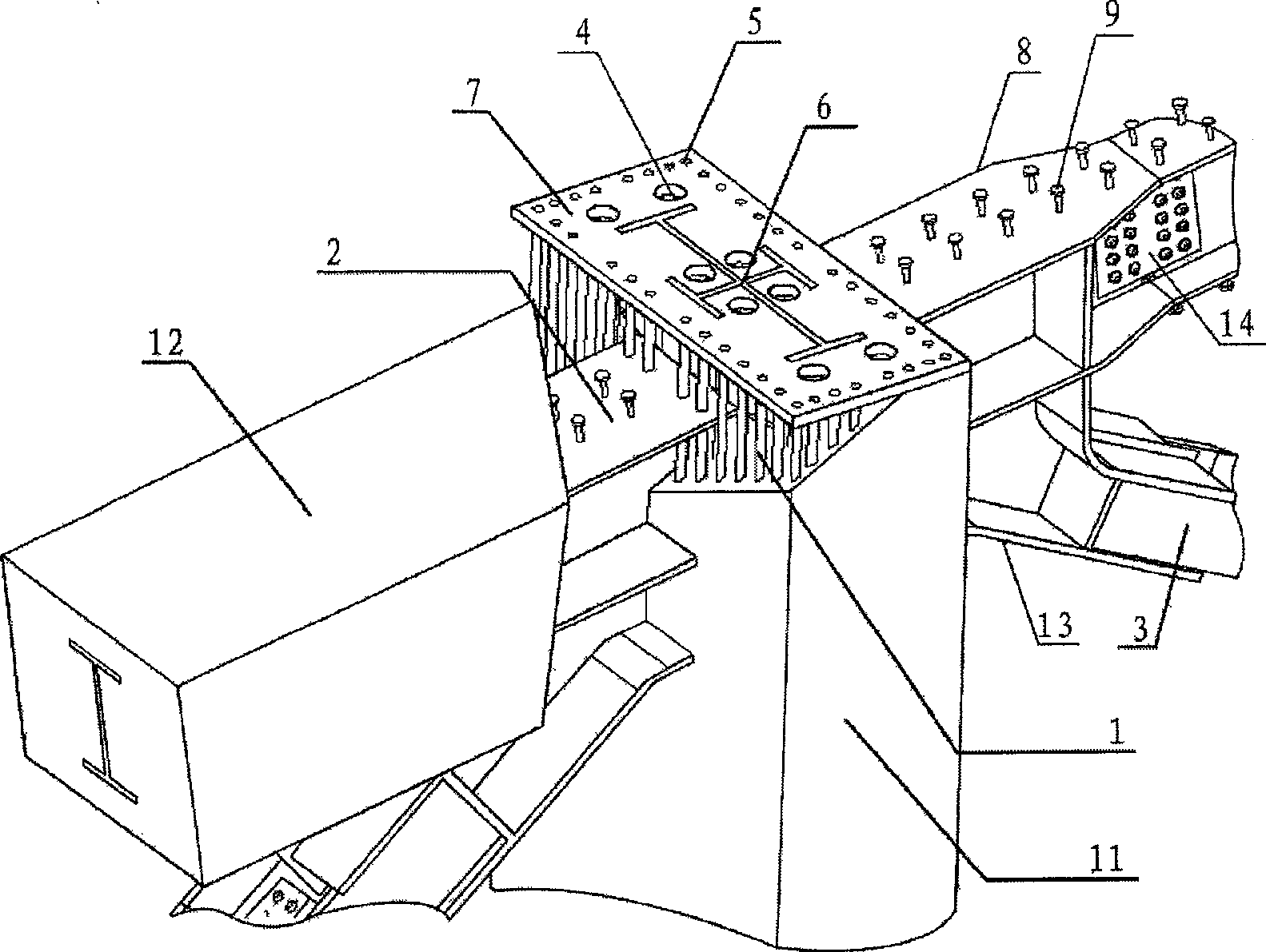

[0027] Examples see Figure 1-3 As shown, this type of steel concrete frame-steel support structure steel column top constrained joint, consists of beams of medium

[0028] Steel 2, column medium steel 10, column main reinforcement 1, steel support 3, column concrete 11, and beam concrete 12 are handed over and poured into one, which is characterized in that a restraint anchor is welded on the top of column medium steel 10 and column main reinforcement 1 The steel plate 7 has a vibrating hole 4 and a welding line hole 6 in the middle of the restraint anchor steel plate 7, and is welded with the section steel to form a weld line in the factory. A plug welding hole 5 is opened on the edge of the restraint anchor steel plate 7, and the main reinforcement of the column 1 and the The restraint anchor steel plate 7 is welded at the plug welding hole 5, and the column mid-section steel 10 is welded with the restraint anchor steel plate 7 at the weld line hole. The main reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com