Method for diagnosing and positioning faults of two position sensors of four-phase switch magnetic resistance motor

A sensor fault, reluctance motor technology, applied in the direction of motor generator testing, instruments, measuring devices, etc., can solve problems such as loss of edge pulses of position sensor output signals, inappropriate operation of switched reluctance motors with speed changes, sensor failures, etc. , to achieve the effect of extensive engineering application value, reliable diagnosis method, and avoid misdiagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

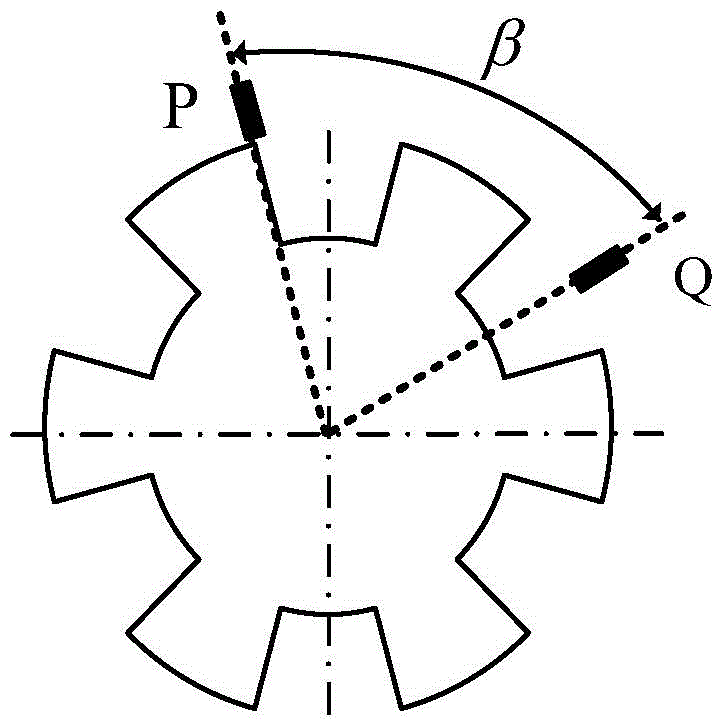

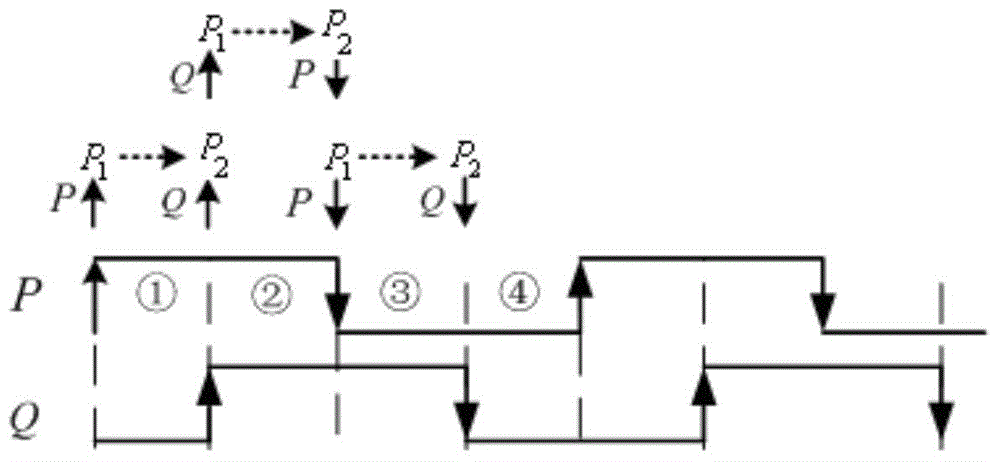

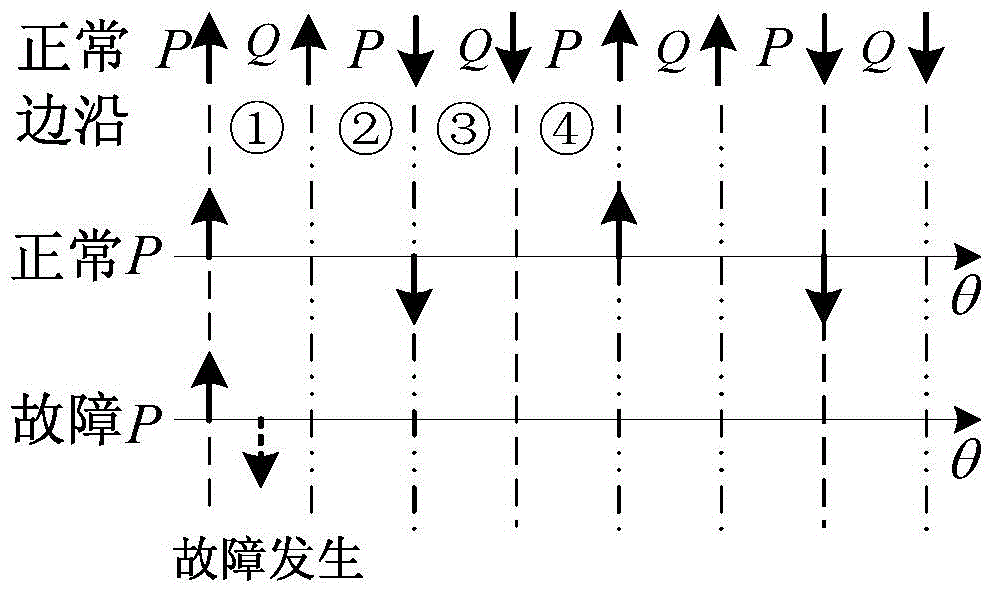

[0024] figure 1 Shown is a schematic diagram of the installation of two position sensors P and Q of a four-phase 8 / 6 structure switched reluctance motor, and the installation angle β of the two position sensors P and Q is 75 degrees. The resulting output signal of the position sensor is as follows: figure 2 As shown, the output signal phase of the switched reluctance motor position sensor P is earlier than the output signal phase of the position sensor Q in time; the rising edge of the output signal of the position sensor P to the rising edge of the output signal of the position sensor Q is the interval ①, The rising edge of the output signal of Q to the falling edge of the output signal of the position sensor P is the interval ②, the falling edge of the output signal of the position sensor P to the falling edge of the output signal of the position sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com