Magnetic structure of magnetic sensitive torque sensor

A torque sensor and magneto-sensitive technology, applied in the field of position sensor sampling, can solve the problems of low efficiency of magnetic flux collection, achieve the effect of improving the efficiency of magnetic flux collection, compact structure, and ingenious overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

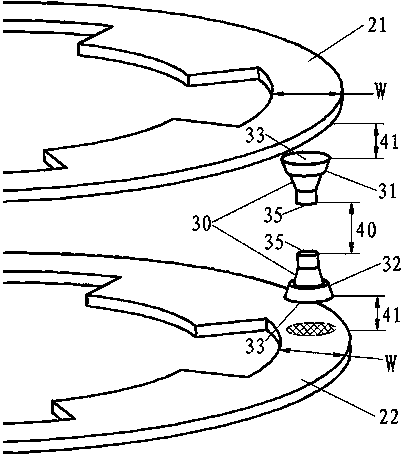

[0032] see figure 1 , Figure 16 , a magnetic circuit structure of a magnetosensitive torque sensor, the magnetic circuit structure includes a magnetic flux collecting structure 30, a magnetic rotor structure 10 and a magnetic flux converging rotor structure 20, and the magnetic flux collecting structure includes two symmetrically arranged The column-type clusters 31, 32 on both sides of the gap 40, the column-type clusters include a collecting surface 33, at least one focusing surface 34 and at least one focusing surface 35, and the magnetic rotor structure 10 includes a multi-pole magnetic ring 11 and The bracket 13 , the magnetic flux converging rotor structure 20 includes magnetic flux converging rings 21 and 22 , the multi-pole magnetic ring 11 and the bracket 13 are arranged between the magnetic flux converging ring 21 and the magnetic flux converging ring 22 . figure 1 Among them, the magnetic flux collection structure 30 includes two column-type clusters 31, 32, the c...

Embodiment 2

[0034] see figure 1 , Figure 15 , Figure 16 , as an improvement of the present invention, the column-type clusters 31, 32 are arranged in the annular space defined by the ring width W of the magnetic flux converging rings 21, 22, without extension and deformation outside the annular space, radial When vibrating, the collection surface will not go beyond the ring width of the magnetic flux converging ring, which can maintain the stability of the magnetic flux on the collection surface; For the magnetic flux converged by the radially inner teeth 23, the axial orientations of the radially inner teeth 23 of the two magnetic flux converging rings coincide, see Figure 15 , the number of teeth of the radial inner teeth 23 is 4, distributed at equal intervals, the radial inner teeth 23 gather the magnetic flux facing the magnetic poles to the magnetic flux converging rings 21, 22; The ring width W is fully covered. The collection surface of the column-type beam cluster is compl...

Embodiment 3

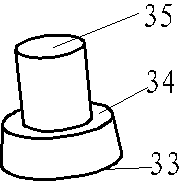

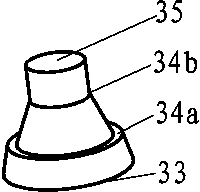

[0036] see figure 2 — Figure 5 , as an improvement of the present invention, see figure 2 , There is a concentrating surface 34 between the collection surface 33 and the focusing surface 35 of the column type concentrator, or a plurality of converging surfaces 34a, 34b, 34c, see image 3 ; Used to narrow the magnetic flux density collected by the enhanced collection surface 33 . Figure 2 to Figure 5 are various forms of column-type clusters, wherein the column-type clusters have only one circular focusing surface 35, figure 2 , image 3 , Figure 4 The collection surface 33 is circular, figure 2 The column cluster has a cluster surface 34, image 3 The column type concentrator has two converging surfaces 34a, 34b, Figure 4 The column type concentrator has three converging surfaces 34a, 34b, 34c. Multiple converging surfaces are provided to further improve the effectiveness of magnetic flux concentrating. The concentrating surfaces can be shaped as cylinders or co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com