Method for detection and prevention of sandstone fissure water in roof sandstone of fully mechanized caving mining face with large mining depth and large span

A coal mining face, large-span technology, applied in mining equipment, earth-moving drilling, mining equipment, etc., can solve the problems of sandstone fissure water and water hazards, and achieve the effect of ensuring safe mining and reasonable analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The present invention provides a large mining depth, large span fully mechanized caving coal mining face roof sandstone fissure water detection method, which is specifically implemented according to the following steps:

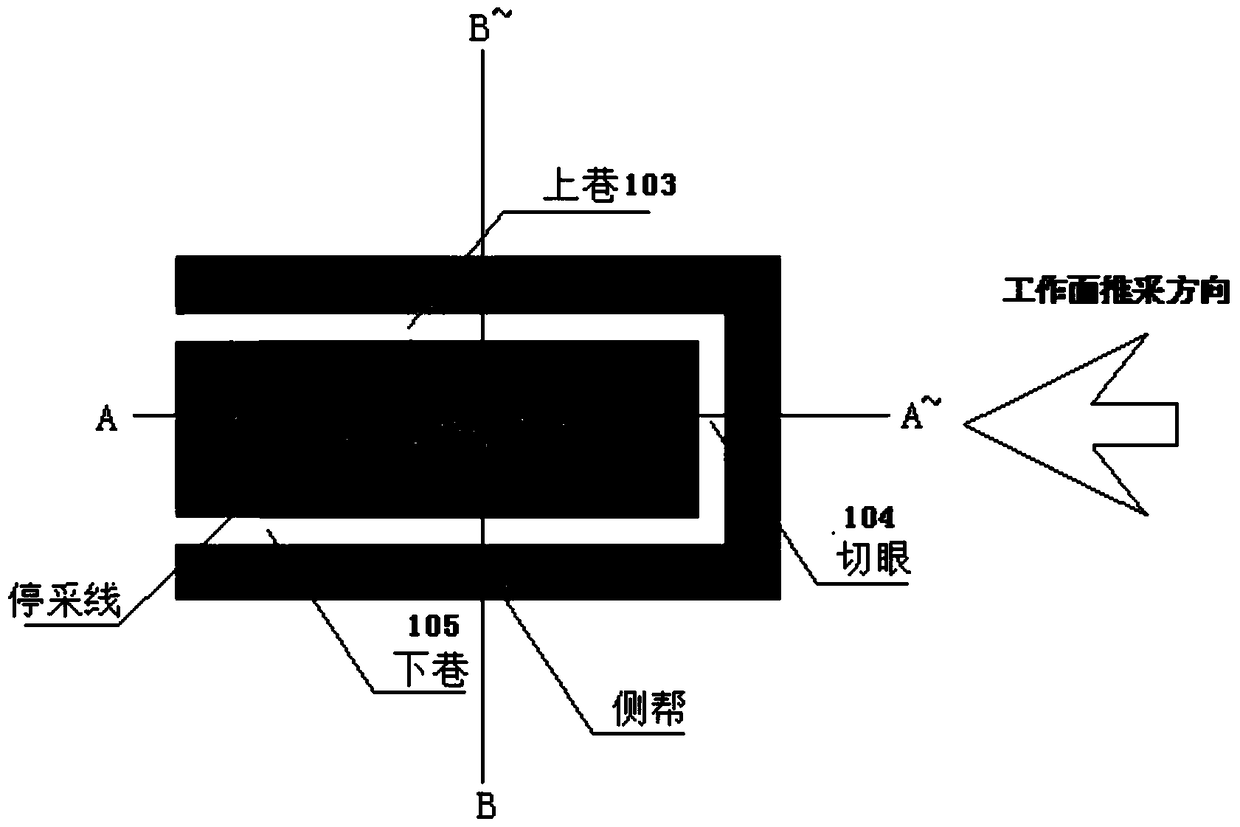

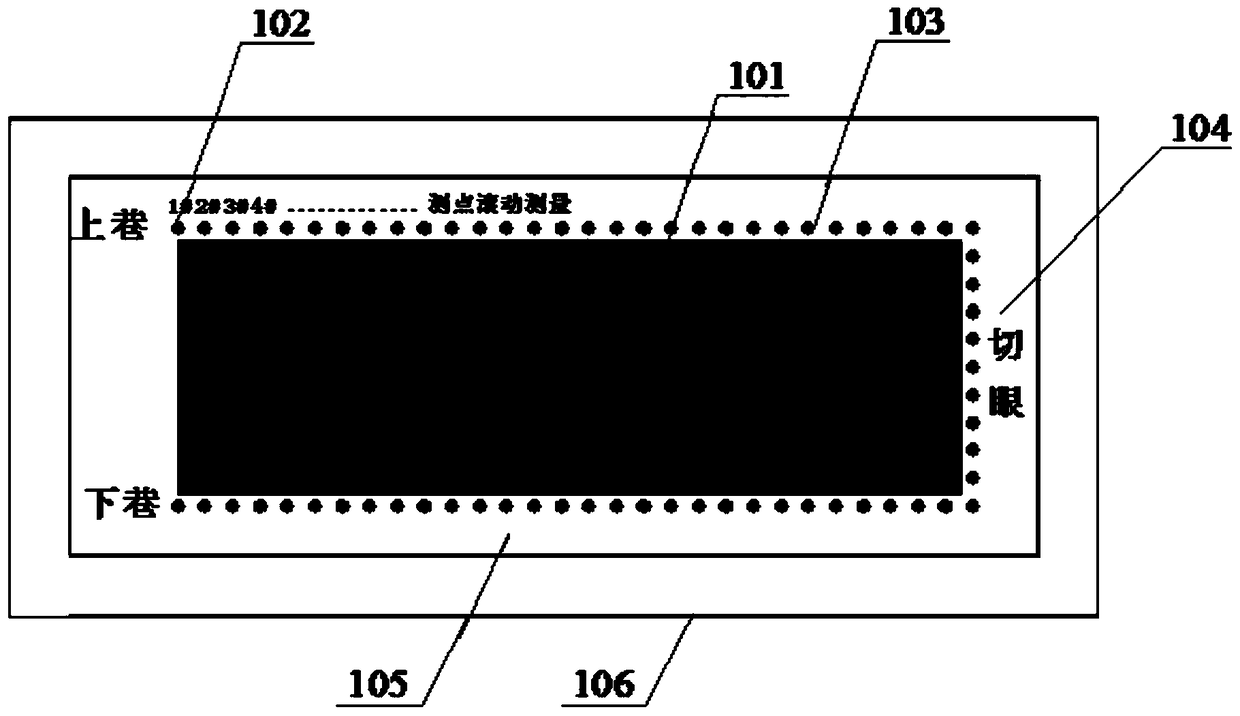

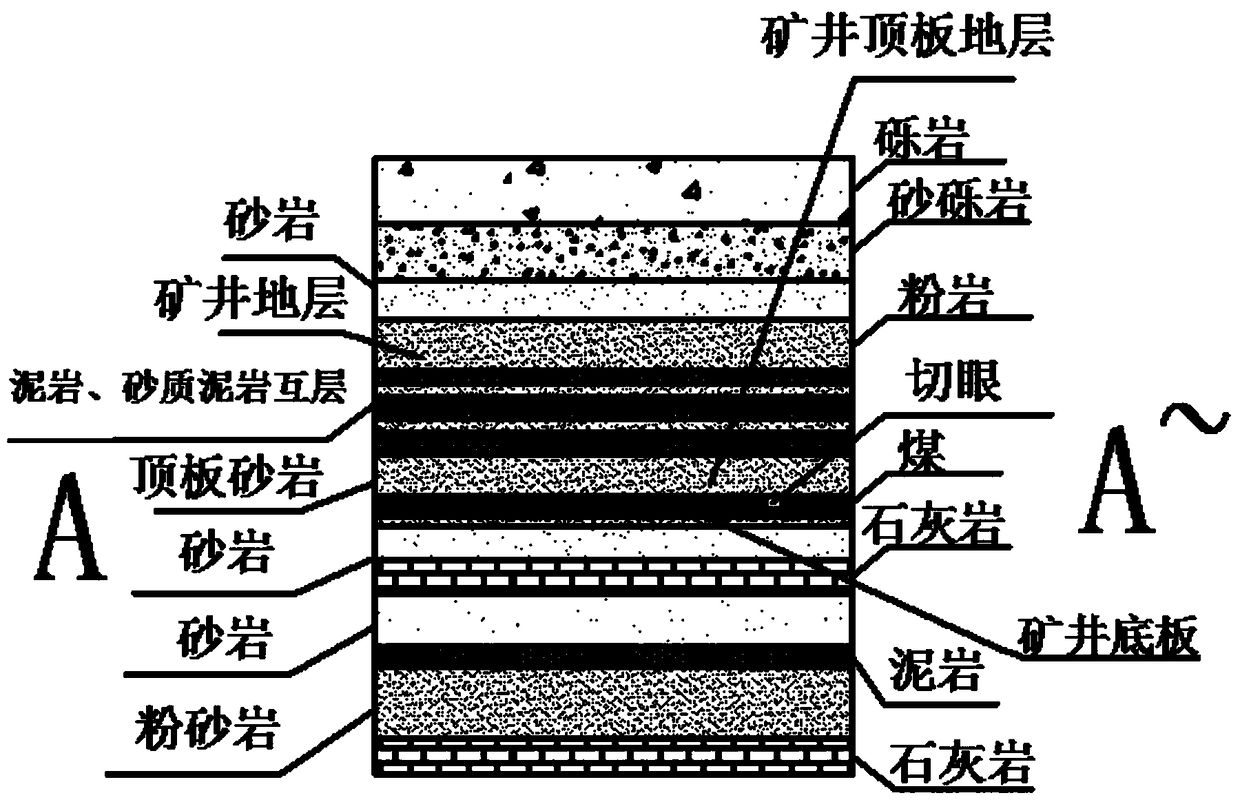

[0025] (1) Pre-mining geophysical prospecting

[0026] Such as figure 1 As shown, after the underground coal mining working face 101 is formed, the underground ultra-high density three-dimensional resistivity method is used to detect the water-rich area of the overlying strata on the working face and the sandstone aquifer above the side of the roadway, as shown in Figure 2-Figure 4 As shown, specifically, the electrodes of the potential device are arranged at the positions of the upper lane 103, the lower lane 105, and the incision 104 of the working face, the electrode point distance is 10m, and the electrode poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com