The Method of Quickly Dismantling the Pile Head by Mechanical Hole Grouting Pile

A technology of mechanical hole-forming and cast-in-place piles, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of the overall quality of the project, the difficulty of stripping steel bars and concrete at the pile head, a large number of labor and mechanical equipment, etc. The quality is easy to guarantee, the pile top elevation is easy to control, and the environmental protection effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

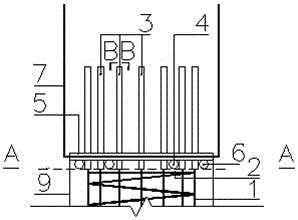

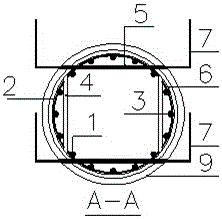

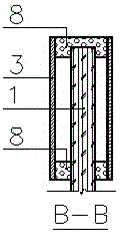

[0024] A method for quickly removing pile heads for mechanical hole-forming cast-in-situ piles, which is constructed according to the following steps:

[0025] First, if Figure 1-3 As shown, before the pile body is poured with concrete, the pile head steel bar is put on, and the plastic sleeve 3 is set on the vertical pile head steel bar 1. The end of the plastic sleeve is sealed with a foaming agent 8, and the pile head steel bar 1 is cut off. With the pile head concrete 9, at the same time, at the position where the pile head is removed (that is, above the spiral hoop 2 of the pile body), two layers of plastic pipes are arranged horizontally. There are 4 plastic pipes arranged horizontally on the upper and lower layers. root, arranged horizontally in the shape of a well, the upper plastic pipe 5 penetrates the steel bar 7 of the lifting ring and the steel bar of the lifting ring bends up to the ground and is temporarily fixed with the ground, the lower plastic pipe 4 is sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com