Yarn controller for guiding yarns before twisting in spinning

A controller and yarn technology, applied in the spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problems of poor fiber convergence, easy to form coarse details, and reduce yarn strength, etc. Achieve the effects of improving production efficiency and product quality, high use value, and reducing coarse details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

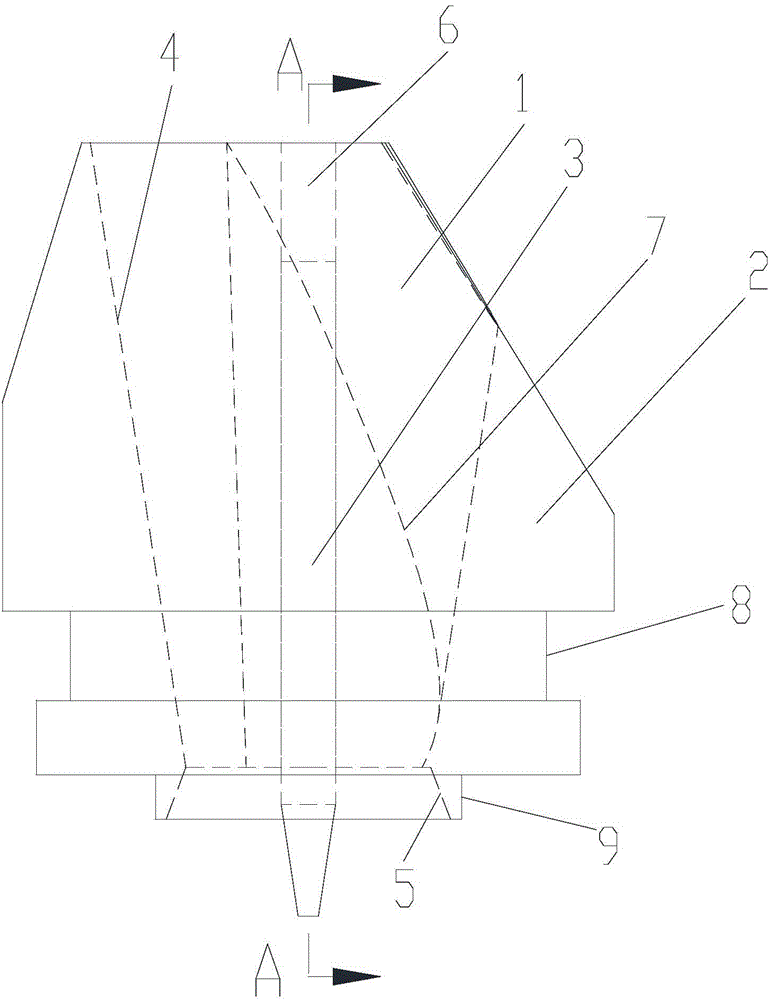

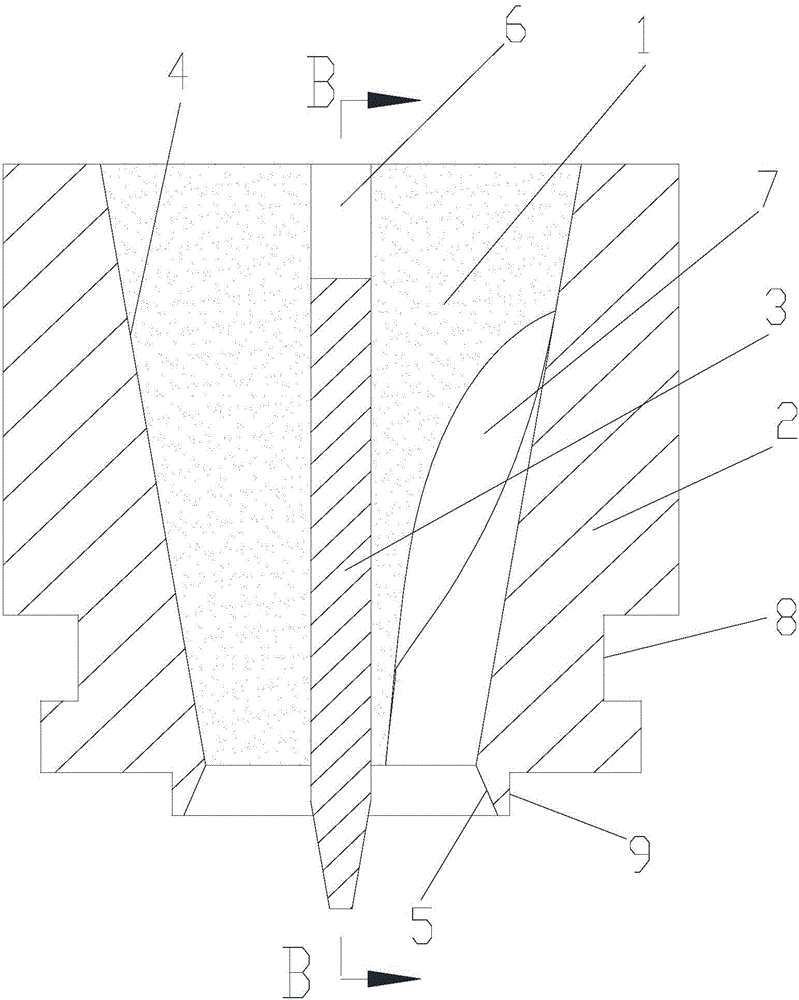

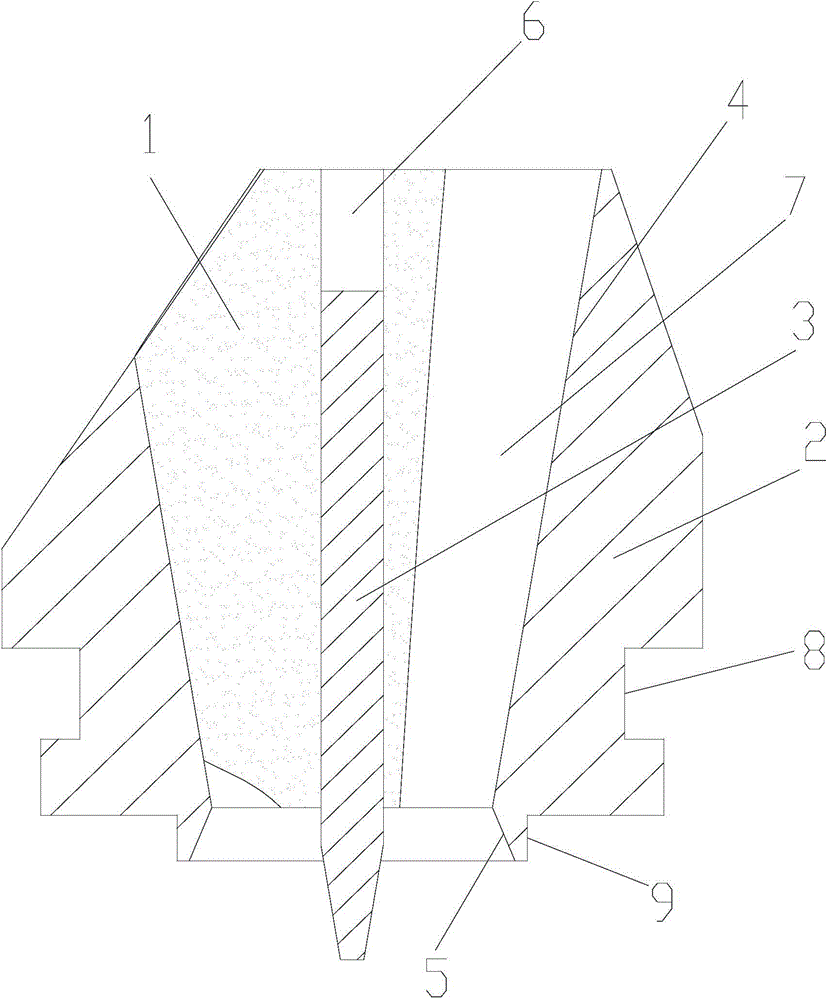

[0019] Attached below Figure 1-6 An embodiment of the present invention is described.

[0020] The yarn controller used for yarn guiding before spinning and twisting has a needle holder 1, a needle holder housing 2 and a needle 3. The outer shape of the needle holder 1 is tapered and a small hole is formed on the outer wall of the needle holder 1 The end to the big end is a helical surface 7 that involutely changes. The needle holder 1 is fixed as a whole after being matched with the tapered hole 4 made on the needle holder housing 2. The lower end of the needle holder housing 2 is formed with a reverse The tapered hole 5 and the reverse tapered hole 5 communicate with the small end of the tapered hole 4. The needle holder 1 is formed with a pinhole 6 and the needle 3 is placed in the needle hole 6. The lower end of the needle 3 extends out of the needle holder 1. And pass through the anti-taper hole 5 and place it outside the needle holder housing 2 and then fix it in the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com