Production method of anaerobic and aerobic probiotic symbiotic metabolic enzyme preparation

A production method and technology of probiotics, which are applied in the production field of anaerobic and aerobic probiotic symbiotic metabolic enzyme preparations, can solve the problems of strain contamination, difficult operation, high price, etc., and are not easy to degenerate, easy to automatically control, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

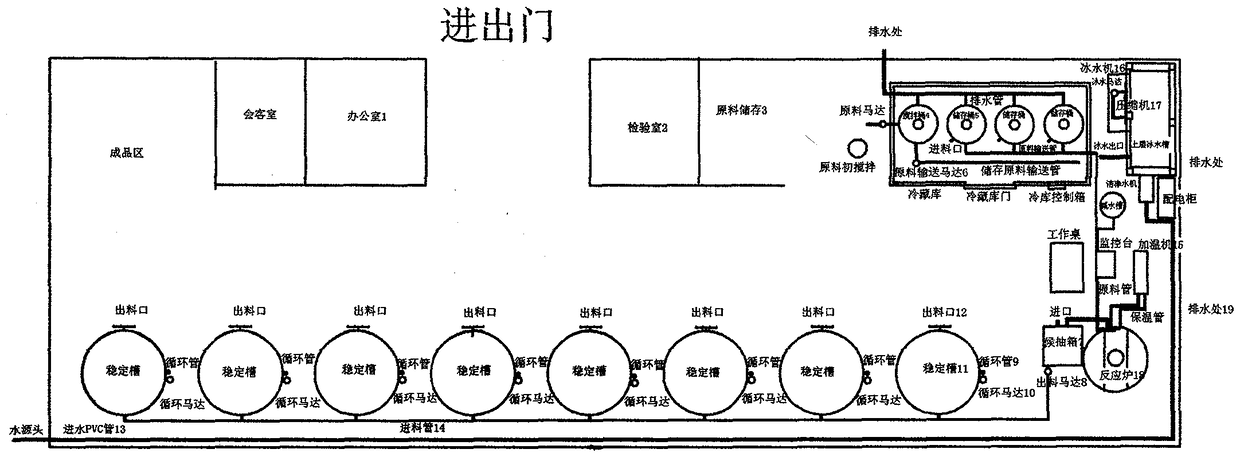

[0019] The production method of anaerobic and aerobic probiotic symbiotic metabolic enzyme preparation of the present invention is the continuous fermentation procedure of anaerobic and aerobic probiotic symbiotic metabolic enzyme, which comprises a special heat preservation substrate refrigerator, an anaerobic fermentation tank, an Circulating heat preservation heaters and back-end storage tanks, the process adopts automatic production, and each process unit is connected to each other to achieve automatic continuous fermentation. Wherein the anaerobic fermentation tank can also be an anaerobic fermentation tank. Back end storage tanks are also known as stabilization tanks.

[0020] The refrigerated cold room of the present invention is equipped with rapid stirring and cooling of the matrix and maintaining the temperature for a long time, and the matrix is regularly and quantitatively injected into the fermenter with anaerobic and facultative probiotics through the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com