Biomass straw briquetting machine with double-layer ring die and pressure roller

A biomass straw and matching technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve problems such as poor working stability and wear of working parts, and achieve the goals of prolonging life, reducing equipment costs, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

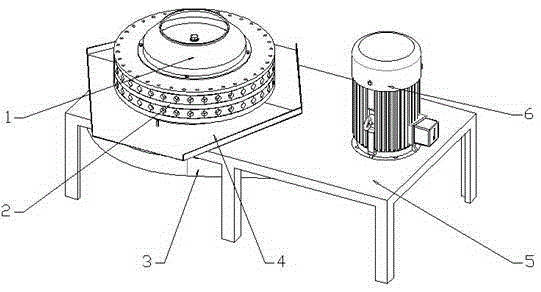

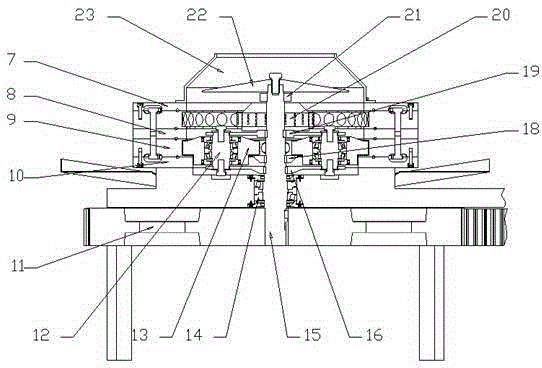

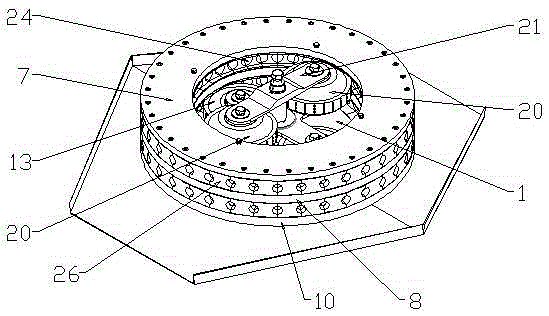

[0036] Specific implementation method: see Figure 1 to Figure 8, a biomass straw briquetting machine with a double-layer ring die and pressure rollers, including a frame 5, a power system and a briquetting system; the power system includes a motor 6, a small pulley, and a synchronous toothed belt 3 and large pulley 11; the briquette forming system includes a double-layer ring die mechanism 2, a hopper 4, a main shaft 15 and a double-layer pressure roller mechanism; the inner chamber of the double-layer ring die mechanism 2 constitutes a compression molding chamber 1, and the double-layer ring The mold mechanism 2 and the motor 6 are installed side by side on the frame 5, the main shaft 15 is installed in the double-layer ring mold mechanism 2, the lower end of the main shaft 15 passes through the frame 5 and is fixedly connected with the large belt pulley 11, and the power shaft of the motor 6 passes through the frame 5. Out of the frame 5 and fixedly connected with the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com