Multilayer co-extrusion high-barrier film and preparation method thereof

A multi-layer co-extrusion, high-resistance technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as defects, complicated production processes, and unclear layers of packaging films, and achieve reduction Energy consumption, good oxygen barrier performance, no solvent residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

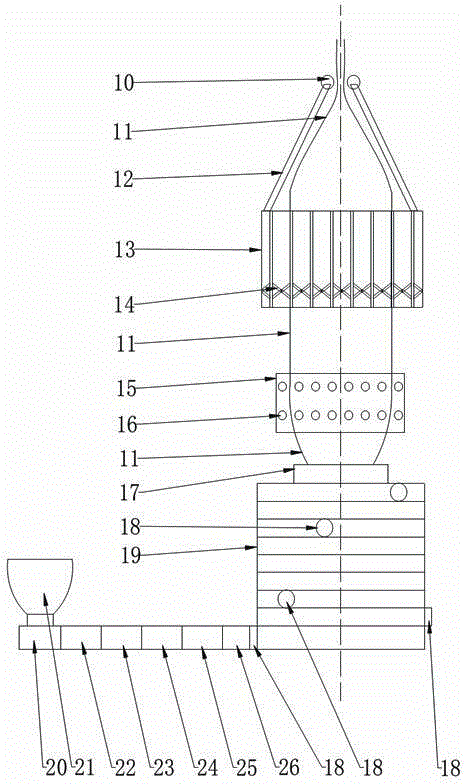

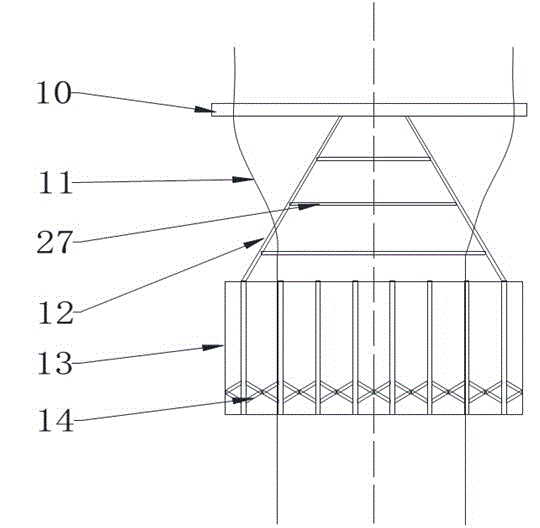

[0066] The technical solution adopted by the present invention is a production equipment for preparing multi-layer co-extruded high-barrier films, including a die head 19, which is a nine-layer co-extrusion die head 19, and the die opening 17 at the upper end of the die head 19 includes 9 annular extrusion dies. Outlet, the 9 extrusion ports are concentric circular structures; the side of the die head 19 is provided with 9 interfaces 18 that are respectively communicated with 9 annular extrusion ports, and each interface 18 is respectively communicated with the outlet of an extruder, extruding After the raw material is heated and melted, the extruder is supplied to the die head 19 for extrusion; the extruder includes a feeding port 20 and a heating zone, a feeding hopper 21 is arranged above the feeding port 20, and the heating zone includes a first heating zone 22 and a second heating zone. 23. The third heating zone 24, the fourth heating zone 25 and the fifth heating zone 26...

Embodiment 2

[0072] Adopt the production equipment of embodiment 1 to manufacture the preparation method of multi-layer co-extruded high barrier film, the steps of this preparation method are:

[0073] (1) Raw material preparation and weighing: Prepare raw material granules according to the components of the nine-layer structure of the multi-layer co-extruded high barrier film, and send the raw material granules into the corresponding extruder hopper 21 through the suction device and weighing mechanism ;

[0074] (2) Extruder shear heating: 9 extruders respectively shear and heat the raw material particles in the hopper 21 to obtain molten raw materials, which are transported to the die head 19 through the interface 18; each extrusion There are five heating areas in the machine, which heat the raw material particles in sequence;

[0075] (3) Extrusion and inflation of the die head 19: Extrude and fuse 9 layers of molten raw materials in the extrusion port of the circular die head 19, and ...

Embodiment 3

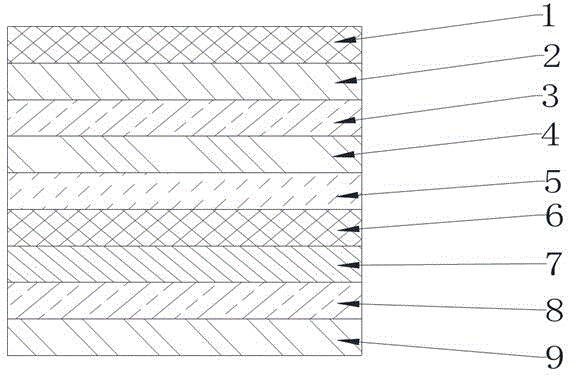

[0097] The multi-layer co-extrusion high barrier film prepared by the preparation method of Example 2, the multi-layer co-extrusion high barrier film has a nine-layer structure, from top to bottom are the first PA layer 1, the first adhesive layer 2. The first PE layer 3, the second adhesive layer 4, the EVOH barrier layer 5, the second PA layer 6, the third adhesive layer 7, the second PE layer 8 and the functional layer 9;

[0098] The thickness of the first PA layer 1 is 7um; the thickness of the first adhesive layer 2 is 20um; the thickness of the first PE layer 3 is 14um; the thickness of the second adhesive layer 4 is 20um; the thickness of the EVOH barrier layer 5 is 4um; The thickness of the layer 6 is 8um; the thickness of the third adhesive layer 7 is 20um; the thickness of the second PE layer 8 is 11um; the thickness of the functional layer 9 is 11um; the functional layer 9 is a heat-sealing layer.

[0099] The component of the first adhesive layer 2 comprises PE an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com